Core/shell fiber with nanowire-embedded microtube structure and preparation method thereof

A technology of microtubes and nanowires, which is applied in the field of core/shell fibers with microtube-in-nanowire structure and its preparation, can solve unfeasible problems, achieve the effects of improving material performance, expanding the selection range, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

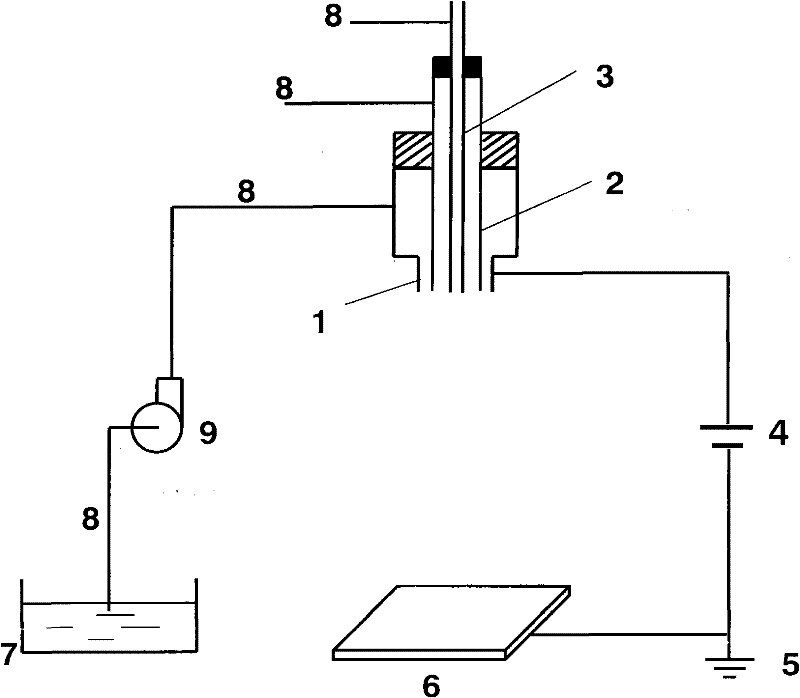

[0043] The three-fluid coaxial electrospinning device utilized in this embodiment is as figure 1 As shown, it includes a composite spinneret assembled coaxially by three stainless steel outer nozzles 1, middle nozzles 2, and inner nozzles 3 of different thicknesses, a DC high-voltage power supply 4, a ground wire 5, a collecting plate 6, and A liquid supply system composed of a liquid storage tank 7, an infusion pipeline 8, and a liquid supply pump 9; between the outer nozzle 1 and the inner nozzle 3 is the middle nozzle 2, the outer nozzle 1 The inner diameter of the nozzle is 2.0-3.0mm, the inner diameter of the middle nozzle 2 is 1.0-2.0mm, and the inner diameter of the inner nozzle 3 is 0.15-1.0mm; the outer nozzle 1, the middle nozzle 2, and the inner nozzle 3 pass through their respective The infusion pipelines 8 are connected to the outlets of the respective liquid supply pumps 9, and the feed ports of the respective liquid supply pumps 9 are connected to the respective...

Embodiment 2

[0050] Adopt the device as embodiment 1, join 2.0g PVP in the mixed solution of 10g ethanol and 2g glacial acetic acid, add 6.0g Ti(OBu) again after stirring and dissolving 4 , and continued to stir for 4 hours to form a homogeneous sol. The sol is used as an external fluid through the liquid supply system at a rate of 5.0-8.0mL·h -1 The velocity is delivered to the outer nozzle.

[0051] Add 2.0g of PVP to the mixture of 10g of ethanol and 2g of glacial acetic acid, stir and dissolve, then add 3.0g of Ti(OBu) 4 And 3.0g triisopropoxyvanadium oxide [VO(OiPr) 3 ], continue stirring for 5 hours to form a uniform sol. The sol is used as the internal fluid through the liquid supply system at a rate of 0.1-1.0mL·h -1 The speed is delivered to the inner nozzle.

[0052] Add 1.0 g of lecithin to 8.5 g of liquid paraffin oil, stir to dissolve, then add 0.5 g of deionized water drop by drop, stir magnetically for 5 hours to form a water-in-oil emulsion, and the stirring speed is 2...

Embodiment 3

[0056] Adopt the device as embodiment 1, join 2.0g PVP in the mixed solution of 9g ethanol and 2g glacial acetic acid, add 7.0g tetra-n-butyl zirconate [Zr(OBu) after stirring and dissolving 4 ], continue stirring for 5 hours to form a uniform sol. The sol is used as the external fluid through the liquid supply system at a rate of 5.0-8.0mL·h -1 The velocity is delivered to the outer nozzle.

[0057] Add 1.8g of PVP to the mixed solution of 12.2g of ethanol and 2g of glacial acetic acid, stir and dissolve, then add 4.0g of germanium isopropoxide [Ge(OiPr) 4 ], continue stirring for 5 hours to form a uniform sol. The sol is used as the internal fluid through the liquid supply system at a rate of 0.1-1.0mL·h -1 The speed is delivered to the inner nozzle.

[0058] Add 0.5 g of lecithin to 9.4 g of peanut oil, stir to dissolve, add 0.1 g of deionized water drop by drop, and magnetically stir for 2 hours to form a water-in-oil emulsion at a stirring speed of 2000 r / min. The em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com