Method for preparing barium strontium titanate nano powder

A technology of nano-powder and barium strontium titanate, which is applied in the field of nano-powder preparation, can solve the problems of difficult control of stoichiometric ratio, large particle size of BST powder, uneven distribution, etc., and achieves short preparation period, uniform composition, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

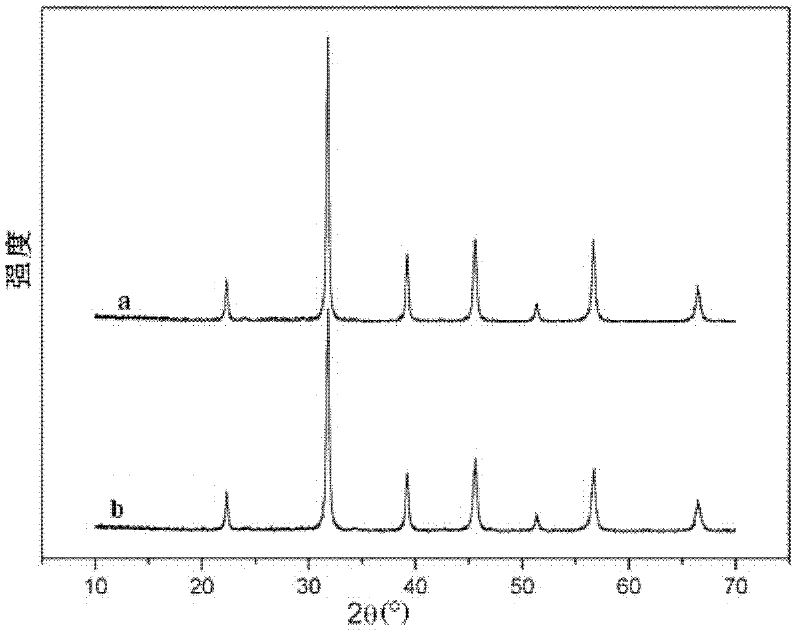

Image

Examples

Embodiment 1

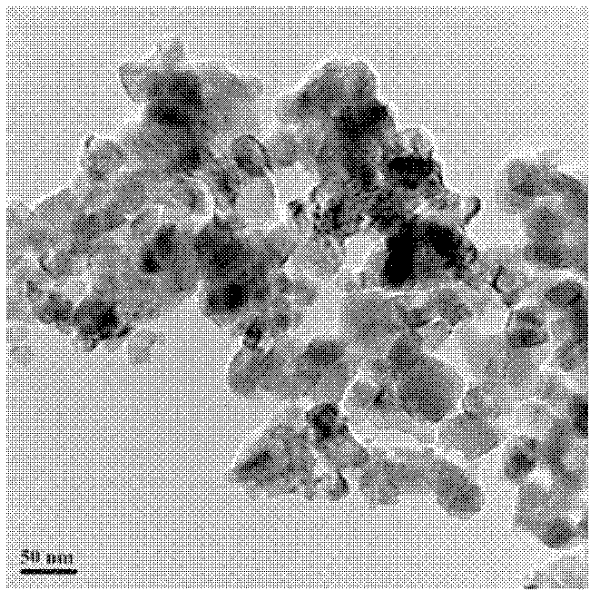

[0028] Take 0.1 mol of tetrabutyl titanate, add 2.0 mol of ethylene glycol, stir until clear; take 0.5 mol of CA powder, slowly add to the above solution, and drop in 48ml of water (add 0.5ml of water per gram of CA Calculation), stirred well until all CA dissolved to obtain a clear solution; according to Ba 0.70 Sr 0.30 TiO 3 The barium carbonate and strontium carbonate powder of stoichiometric ratio are mixed and ground in a mortar, and this mixed powder is slowly added in the above-mentioned clear solution, and a small amount of concentrated nitric acid is dripped (calculated by dripping 3 drops per 100ml solution), fully Stir until all the carbonates are dissolved to obtain a transparent light brown solution. Heat the above light brown solution in an oil bath at 55°C for 2 hours to form a sol-like substance; put the above-mentioned sol-like substance in an oven and keep it at 140°C for 20 hours, and finally turn black The viscous resin; the black viscous resin was carbon...

Embodiment 2

[0033] The difference between this example and Example 1 is only that the molar ratio (CA / M) of citric acid to total metal ions is 5.0, and the remaining contents are the same as those described in Example 1.

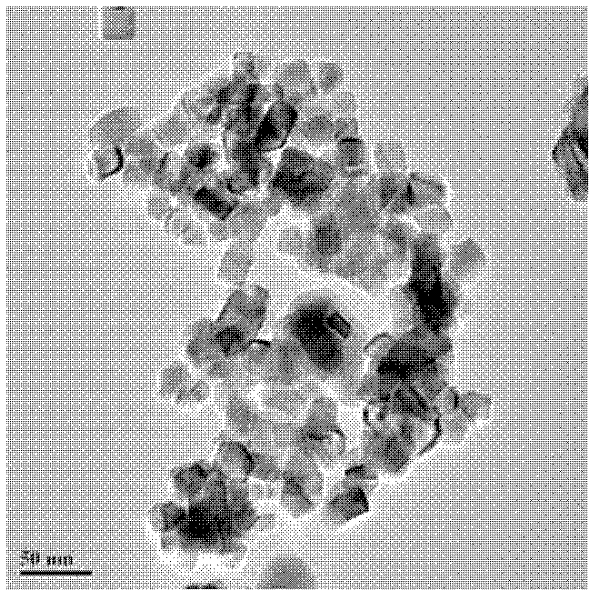

[0034] image 3 It is a TEM image of the barium strontium titanate powder prepared in this example. Depend on image 3 It can be seen that the particle size of the prepared strontium barium titanate powder is very small, about 15-25nm, which is close to the calculation result of XRD, the powder distribution is uniform, and the agglomeration degree is very low.

[0035] In summary, the nano-powder prepared by the method of the present invention has small particle size, light agglomeration, and uniform distribution, and the method has simple process, short cycle, cheap and easy-to-obtain raw materials, and does not require special equipment. It is suitable for large-scale production and is expected to obtain industrial applications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com