Method for preparing ZnS quantum dot modified by mercaptoacetic acid

A technology of thioglycolic acid and quantum dots, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of cumbersome operation process, long time consumption, etc., and achieve the effects of simple preparation process, good dispersibility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

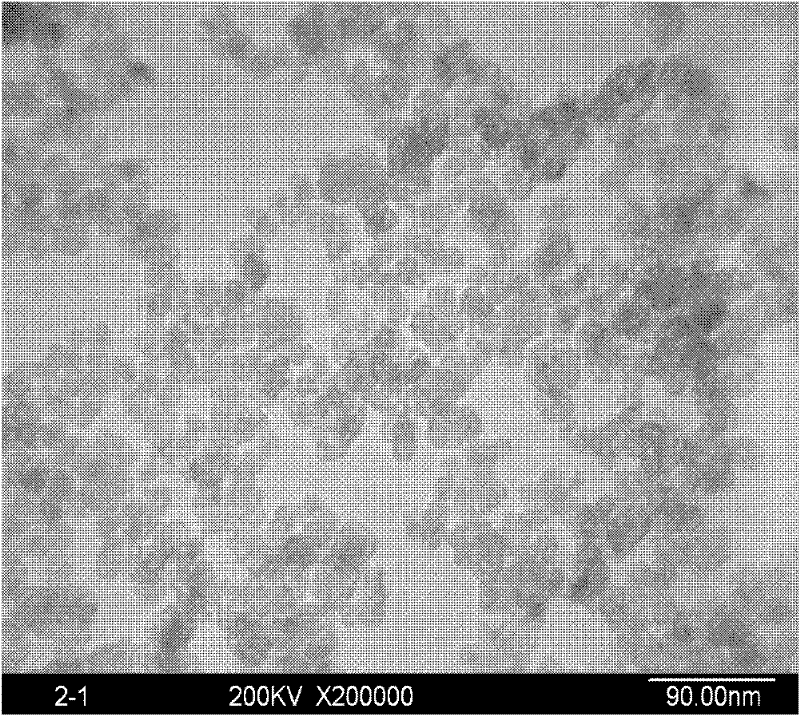

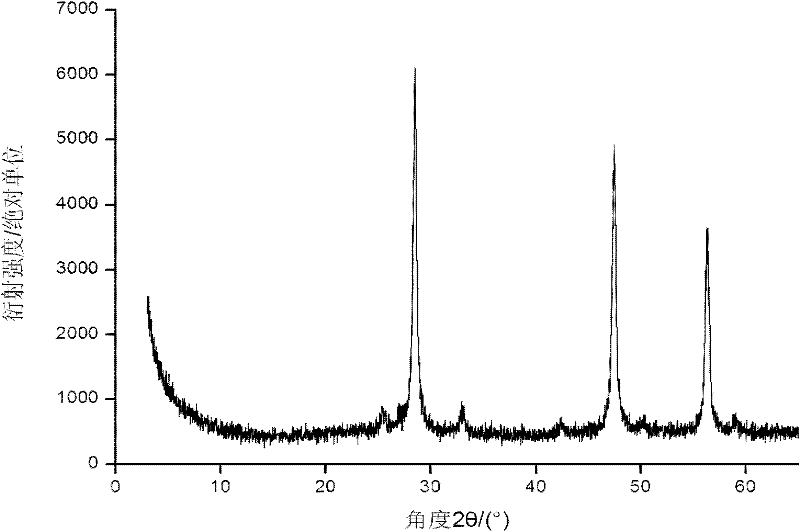

[0022] 2.20g Zn(Ac) 2 2H 2 O (10mmol) was added to 50mL of deionized water to make Zn(Ac) with a concentration of 0.20mol / L 2 2H 2 O aqueous solution, add 4.5 mL of thioglycolic acid with a mass concentration of 90% under magnetic stirring, thioglycolic acid and Zn(Ac) 2 2H 2 The molar ratio of O is 5:1, then add 2.4g Na 2 S·9H 2 O (10mmol), Na 2 S·9H 2 O and Zn(Ac) 2 2H 2 The molar ratio of O is 1:1, adjust the pH=10 with ammonia water with a mass concentration of 25%, put it into a polytetrafluoroethylene high-pressure reactor after stirring evenly, the volume of the mixed solution accounts for 60% of the reactor volume, 130°C Keep warm for 14 hours. After the reaction kettle is naturally cooled, centrifuge and discard the supernatant, wash the precipitate twice with 20mL of absolute ethanol, then wash the precipitate twice with 20mL deionized water, and disperse the precipitate in deionized water to obtain a stable hydrosol; or dissolve the precipitate Vacuum dry...

Embodiment 2

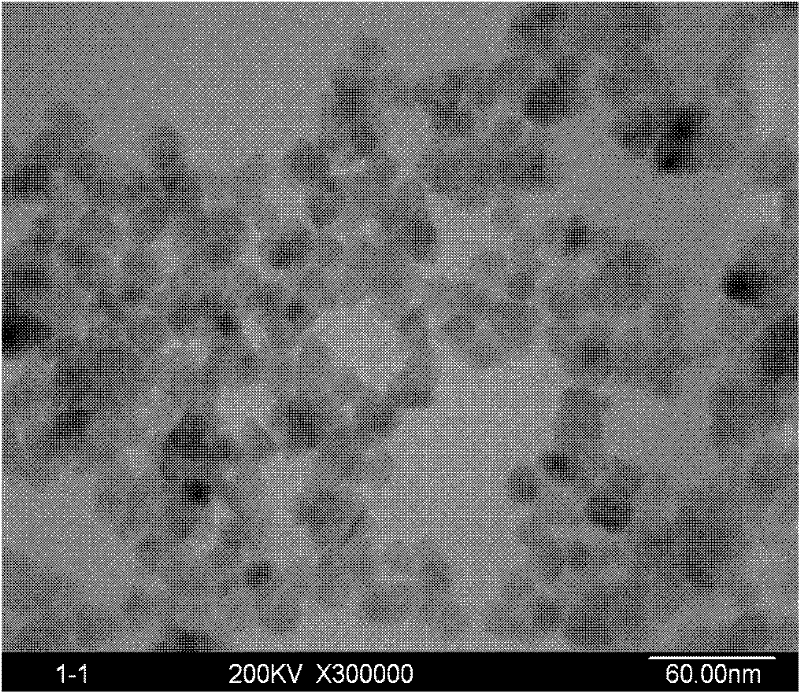

[0025] 1.32g Zn(Ac) 2 2H 2 O (6mmol) was added to 50mL of deionized water to make Zn(Ac) with a concentration of 0.12mol / L 2 2H 2 O aqueous solution, add 4.5 mL of thioglycolic acid solution with a mass concentration of 90% under magnetic stirring, thioglycolic acid and Zn(Ac) 2 2H 2 The molar ratio of O is 9:1, then add 2.16g Na 2 S·9H 2 O (9 mmol), Na 2 S·9H 2 O and Zn(Ac) 2 2H 2 The molar ratio of O is 1.5:1, adjust the pH=9 with ammonia water with a mass concentration of 25%, put it into a polytetrafluoroethylene high-pressure reactor after stirring evenly, the volume of the mixed solution accounts for 60% of the reactor volume, 150°C Keep warm for 10 hours. After the reaction kettle is naturally cooled, centrifuge and discard the supernatant, wash the precipitate twice with 20mL of absolute ethanol, and then wash the precipitate twice with 20mL of deionized water. The precipitate is directly dispersed in deionized water to obtain a stable hydrosol; or The preci...

Embodiment 3

[0027] 3.96g Zn(Ac) 2 2H 2 O (18mmol) was added to 50mL of deionized water to make Zn(Ac) with a concentration of 0.36mol / L 2 2H 2 O aqueous solution, add 4.5 mL of thioglycolic acid solution with a mass concentration of 90% under magnetic stirring, thioglycolic acid and Zn(Ac) 2 2H 2 The molar ratio of O is 3:1, then add 6.48g Na 2 S·9H 2 O (27mmol), Na 2 S·9H 2 O and Zn(Ac) 2 2H 2 The molar ratio of O is 1.5:1, adjust the pH=9 with ammonia water with a mass concentration of 25%, put it into a polytetrafluoroethylene high-pressure reactor after stirring evenly, the volume of the mixed solution accounts for 60% of the reactor volume, 180°C Keep warm for 6 hours. After the reaction kettle is naturally cooled, centrifuge and discard the supernatant, wash the precipitate twice with 20mL of absolute ethanol, then wash the precipitate twice with 20mL of deionized water, and disperse the precipitate in deionized water to obtain a stable hydrosol; or place the precipitate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com