Core-shell type magnetic mesoporous nano-microsphere as well as preparation method and application thereof

A technology of nano-microspheres and core-shells, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., to achieve the effect of large adsorption capacity and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] (2) Preparation of ferric oxide nanoparticles: 0.02molL -1 The ferric chloride was aged at 100°C for 48 hours, then centrifuged at 6000 rpm to obtain a red precipitate, which was washed three times with water and ethanol respectively, and finally dissolved in water to obtain ferric oxide nanoparticles with a diameter of 100nm-150nm aqueous solution.

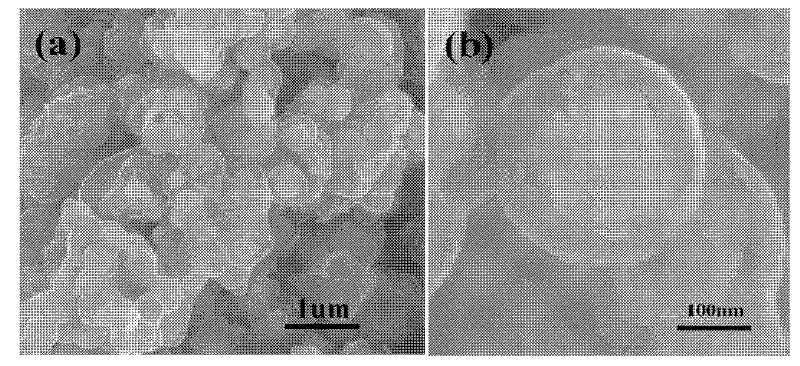

[0027] (3) Iron oxide coated with silicon dioxide (FeO x @nSiO 2 ) preparation: Dissolve 0.3g ferric oxide or ferric oxide nanoparticles in a mixed solution of 160ml ethanol and 40ml water, ultrasonic for 10 minutes, then place the mixed solution in a 250ml round bottom flask, mechanically stir Add 3.5ml of ammonia water with a mass concentration of 25%-28%, stir for 15 minutes, add 1ml-2ml tetraethoxysilane, continue stirring for 6-10h, and finally wash the obtained product three times with water and ethanol, namely Get FeO with a diameter of 100nm-380nm x @nSiO 2 .

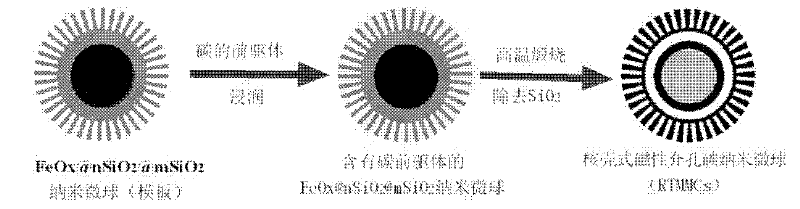

[0028] (4) FeO x @nSiO 2 @mSiO 2 Preparation ...

Embodiment 1

[0029] Embodiment 1, preparation of core-shell magnetic mesoporous carbon nanospheres (RTMMCs)

[0030] (1) Mesoporous carbon / FeO x @nSiO 2 @mSiO 2 Preparation of complex

[0031] Add 60wt% furfural in trimethylbenzene dropwise to 1g FeO x @nSiO 2 @mSiO 2 In the template material, stop adding when it is just completely wet, then dry it in vacuum below 50°C, repeat this step twice, then put it in an oven at 50°C for two days, and then bake and cure at 90°C for one day. Then put it under the protection of argon for calcination and carbonization at 700°C for 8 hours to obtain mesoporous carbon / FeO x @nSiO 2 @mSiO2 Complex;

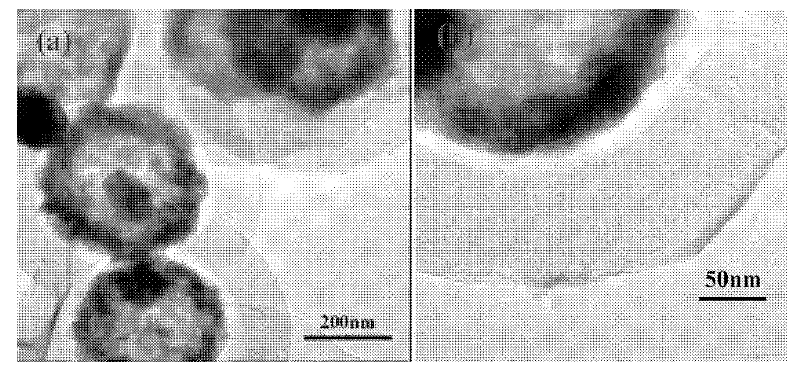

[0032] (2) Preparation of core-shell magnetic mesoporous carbon nanosphere RTMMCs

[0033] mesoporous carbon / FeO x @nSiO 2 @mSiO 2 The complex was dissolved in 100ml 5Wt% sodium hydroxide aqueous solution (mesoporous carbon / FeO x @nSiO 2 @mSiO 2 The mass fraction ratio of the composite to sodium hydroxide was 1:5), refluxed for 3 hours, and the...

Embodiment 2

[0035] Embodiment 2, preparation of core-shell magnetic mesoporous carbon nanospheres (RTMMCs)

[0036] (1) Mesoporous carbon / FeO x @nSiO 2 @mSiO 2 Preparation of complex

[0037] With the step in the step (1) of embodiment 1, difference is: the concentration of the trimethylbenzene solution of furfural is 20Wt%.

[0038] (2) Preparation of core-shell magnetic mesoporous carbon nanosphere RTMMCs

[0039] Same as the steps in step (2) of Example 1, the diameter of RTMMCs is 350nm, and the pore size is 3nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com