Advanced treatment magnetic resin for recycling sewage landscape containing two quaternary ammonium sites and capable of synchronously removing nitrogen and phosphorus and preparation method of advanced treatment magnetic resin

A magnetic resin and advanced treatment technology, applied in the field of resin materials, can solve the problems of the easily damaged release mechanical strength of the magnetic core, the low selectivity of nitrogen and phosphorus substances, the secondary pollution of water bodies, etc., and achieves good recycling effect, simple preparation method, Reduce the effect of shattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

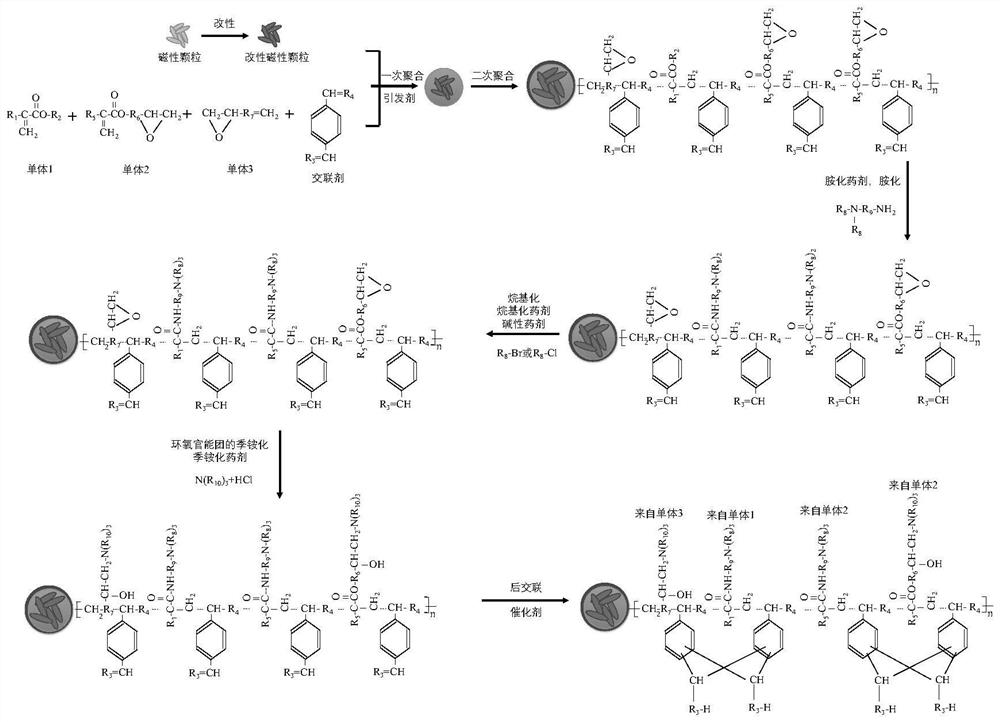

[0058] A preparation method of the above-mentioned magnetic resin for advanced treatment of sewage landscape reuse containing two types of quaternary ammonium sites for simultaneous removal of nitrogen and phosphorus. Agent and modified magnetic particles are mixed into an oil phase, and after mixing, a suspension polymerization is carried out in the water phase, and the magnetic white spheres after the primary polymerization are further subjected to secondary polymerization to obtain secondary copolymerized magnetic microspheres. The ester group is sequentially aminated and alkylated to form a type of quaternary ammonium salt, the epoxy group and the amine salt are further reacted to obtain another type of quaternary ammonium salt, and finally the double bond on the other side of the benzene ring on the cross-linking agent is carried out. After the post-crosslinking reaction, a magnetic strong basic anion resin containing two types of quaternary ammonium sites for simultaneous...

Embodiment 1

[0123] Dissolve 3.0g γ-iron trioxide in 200mL deionized water in a 250mL conical flask, add 25mL ammonia water (25-28wt%), 2.5mL oleic acid, 13mL acetone, stir mechanically in a water bath at 80°C for 30min, wash with ethanol for 3 times, The oleic acid modified magnetic powder was obtained by washing with ultrapure water for 3 times and drying at 60°C. The oil phase was added to the 250ml conical flask dried above, and the oil phase contained 10.0g methyl methacrylate, 2.0g divinylbenzene, 2.0g glycidyl methacrylate, 0.3g 3,4-epoxy-1 - Butene, 0.24 g dibenzoyl peroxide, 8 mL toluene and 6 mL n-heptane. Add 1.8g of polyvinyl alcohol, 1.8g of polyvinylpyrrolidone and 8g of NaCl to 200mL of deionized water as the water phase, transfer the water phase to the oil phase, and then transfer the 250ml conical flask with a stopper to a water bath, and use temperature-programmed heating , the temperature was raised from room temperature to 70°C, and the heating rate was 1°C / min. After ...

Embodiment 2

[0127] Dissolve 2.5g γ-iron trioxide in 200mL deionized water in a 250mL conical flask, add 25mL ammonia water (25-28wt%), 2.5mL oleic acid, 13mL acetone, stir mechanically in a water bath at 80°C for 30min, wash with ethanol 3 times, Washed with ultrapure water 3 times and dried at 60°C. Add the oil phase to the 250ml Erlenmeyer flask dried above, the oil phase contains 10.0g ethyl 2-ethyl acrylate, 2.0g divinylbenzene, 2.0g glycidyl methacrylate, 0.5g 3,4-epoxy -1-Butene, 0.24 g dibenzoyl peroxide, 8 mL toluene and 6 mL n-heptane. Add 1.8g of polyvinyl alcohol, 1.8g of polyvinylpyrrolidone and 8g of KCl to 200mL of deionized water as the water phase, transfer the water phase to the oil phase, and then transfer the 250ml conical flask with a stopper to a water bath, and use temperature-programmed heating , the temperature was raised from room temperature to 70°C, and the heating rate was 1°C / min. After 150 minutes of reaction, the temperature was raised to 80°C at the same h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com