A kind of environment-friendly adsorption material and preparation method of pottery clay/pyrolulurite for efficient phosphorus removal

An adsorption material, pyrolusite technology, which is applied in the field of clay/pyrolulurite high-efficiency phosphorus removal environmental protection adsorption materials and its preparation, can solve the problems of difficult solid-liquid separation, high filtration resistance, easy to block equipment, etc., and achieve good application prospects and low cost. Inexpensive, inexpensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

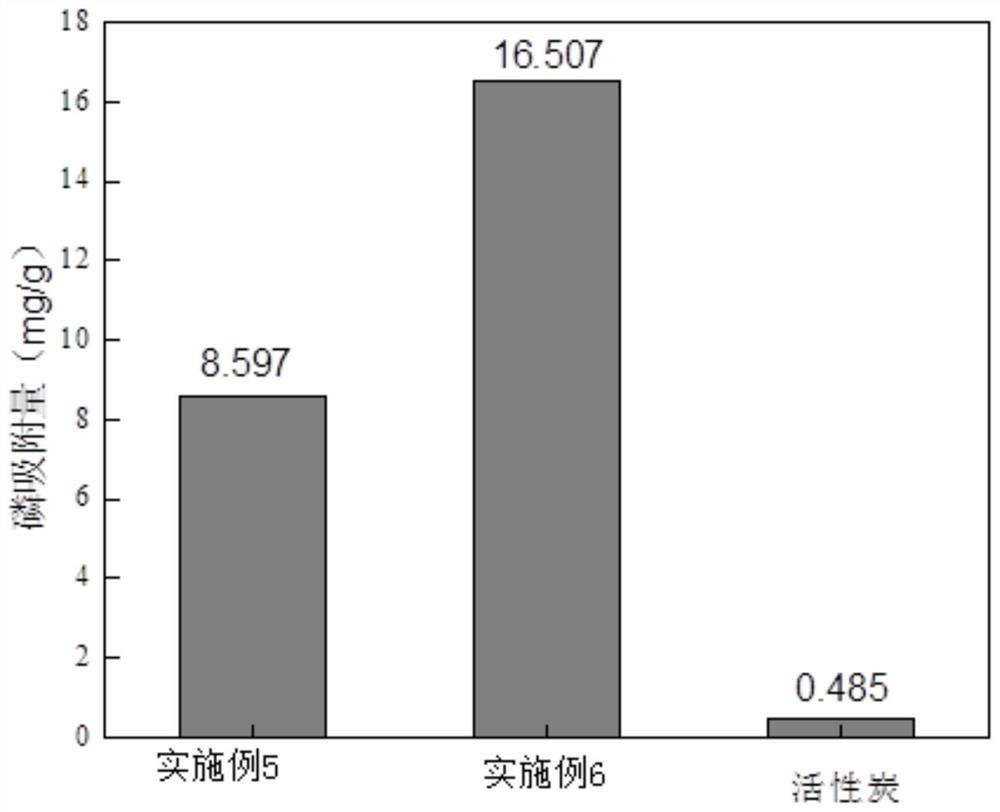

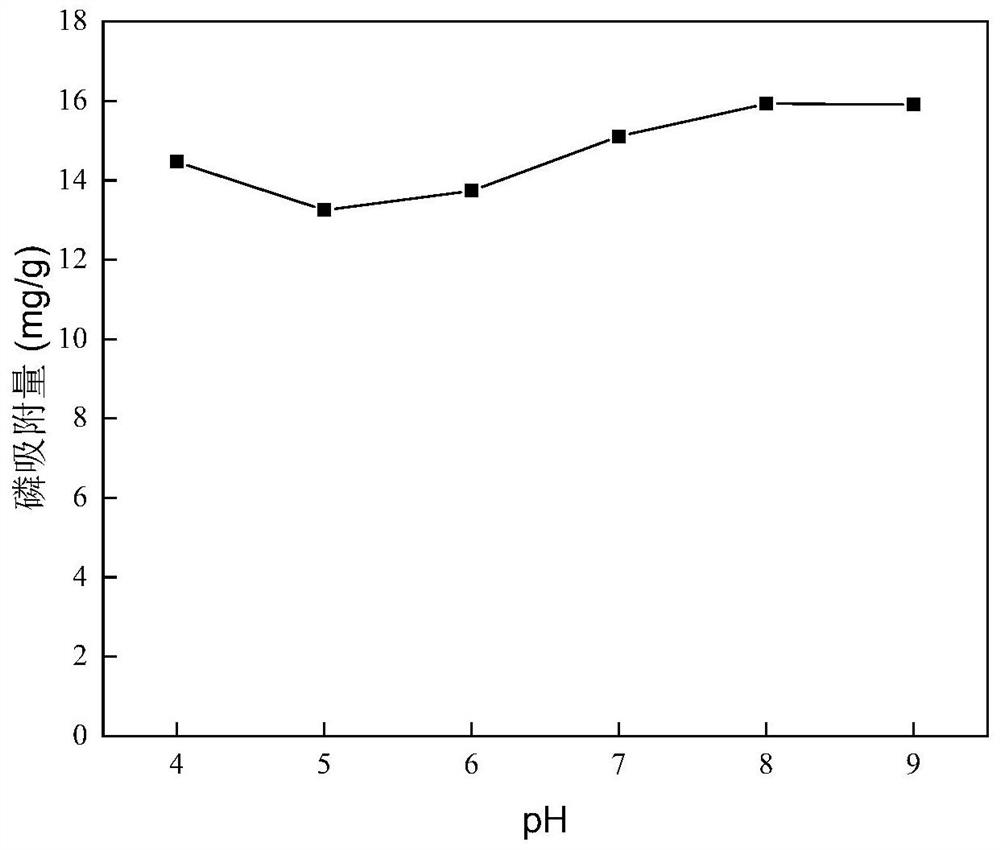

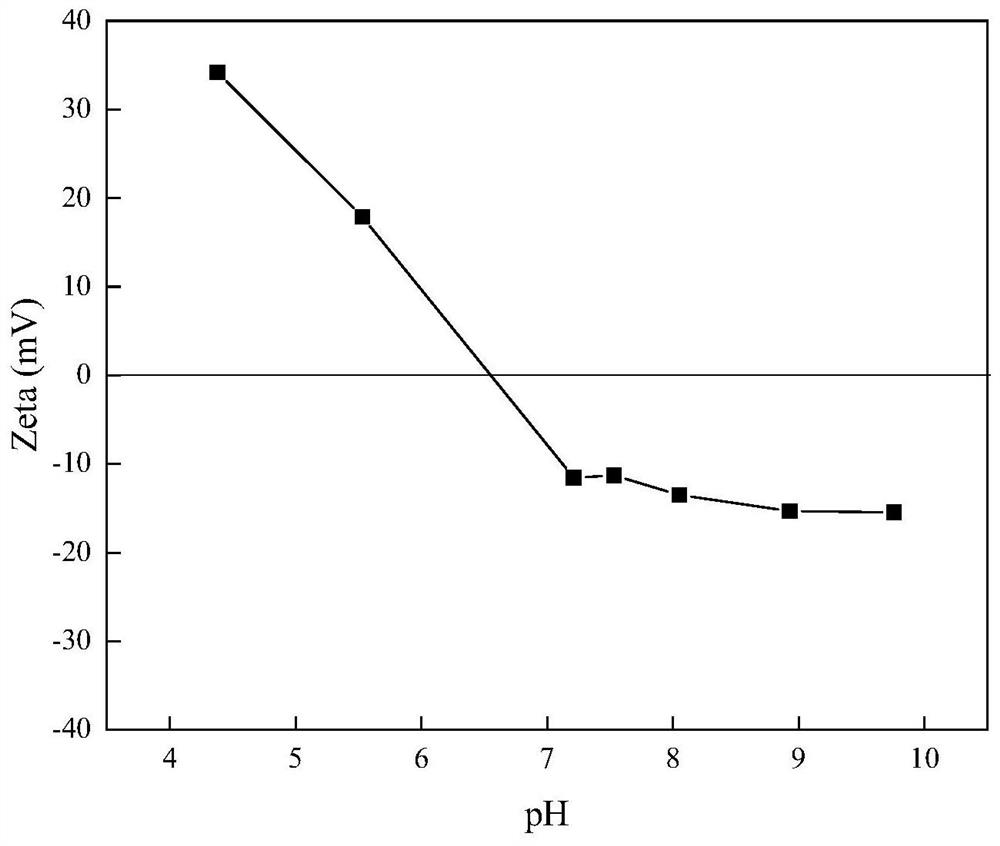

Examples

Embodiment 1

[0041] The high-efficiency phosphorus removal adsorption material of pottery clay / pyrolulusite comprises solid material and water, and the solid material and water are mixed and then air-dried, dried, sintered and cooled, wherein the solid material includes 80 parts by weight of pottery clay, 1 part of pyrolusite and 1 part of sodium silicate, based on the total amount of fixed materials, the mass ratio of solid material: water = 1:0.4. Mainly use the adsorption performance of pyrolusite, and add clay and sodium silicate at the same time, sintered into ceramsite for phosphorus removal.

[0042] The specific preparation method is as follows:

[0043] (1) Raw material processing: sieve pottery clay and pyrolusite respectively;

[0044] (2) Ingredients: Weigh pottery clay, pyrolusite and sodium silicate, mix well;

[0045] (3) Blank making: after the above-mentioned ingredients are evenly mixed with water, put into a mold and form a columnar material;

[0046] (4) Natural air ...

Embodiment 2

[0053] The high-efficiency phosphorus removal adsorption material of pottery clay / pyrolulusite comprises solid material and water, and the solid material and water are mixed and then air-dried, dried, sintered and cooled, wherein the solid material includes 90 parts by weight of pottery clay, 10 parts of pyrolusite and 10 parts of sodium silicate, based on the total amount of fixed materials, the mass ratio of solid material: water = 1:0.6.

[0054] The specific preparation method is as follows:

[0055] (1) Raw material processing: sieve pottery clay and pyrolusite respectively;

[0056] (2) Ingredients: Weigh pottery clay, pyrolusite and sodium silicate, mix well;

[0057] (3) Blank making: after the above-mentioned ingredients are evenly mixed with water, put into a mold and form a columnar material;

[0058] (4) Natural air drying: put the columnar material in the environment to air dry naturally;

[0059] (5) Drying: Put the air-dried columnar material in an oven and d...

Embodiment 3

[0063] The clay / pyrolulurite high-efficiency phosphorus removal adsorption material comprises solid material and water, and the solid material and water are mixed and then air-dried, dried, sintered and cooled, wherein the solid material includes 85 parts by weight of clay, 6 parts by weight of pyrolusite and 4 parts of sodium silicate, based on the total amount of fixed materials, the mass ratio of solid material: water = 1:0.5.

[0064] The specific preparation method is as follows:

[0065] (1) Raw material processing: sieve pottery clay and pyrolusite respectively;

[0066] (2) Ingredients: Weigh pottery clay, pyrolusite and sodium silicate, mix well;

[0067] (3) Blank making: after the above-mentioned ingredients are evenly mixed with water, put into a mold and form a columnar material;

[0068] (4) Natural air drying: put the columnar material in the environment to air dry naturally;

[0069] (5) Drying: put the air-dried columnar material into an oven, the drying te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com