Methanation catalyst, preparation process thereof and methanation reaction device

A methanation catalyst and preparation technology, which is applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, and hydrocarbon production from carbon oxides, etc., can solve the problems of high flow rate, burning of cooling equipment, membrane State boiling and other problems to achieve the effect of ensuring quality, ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

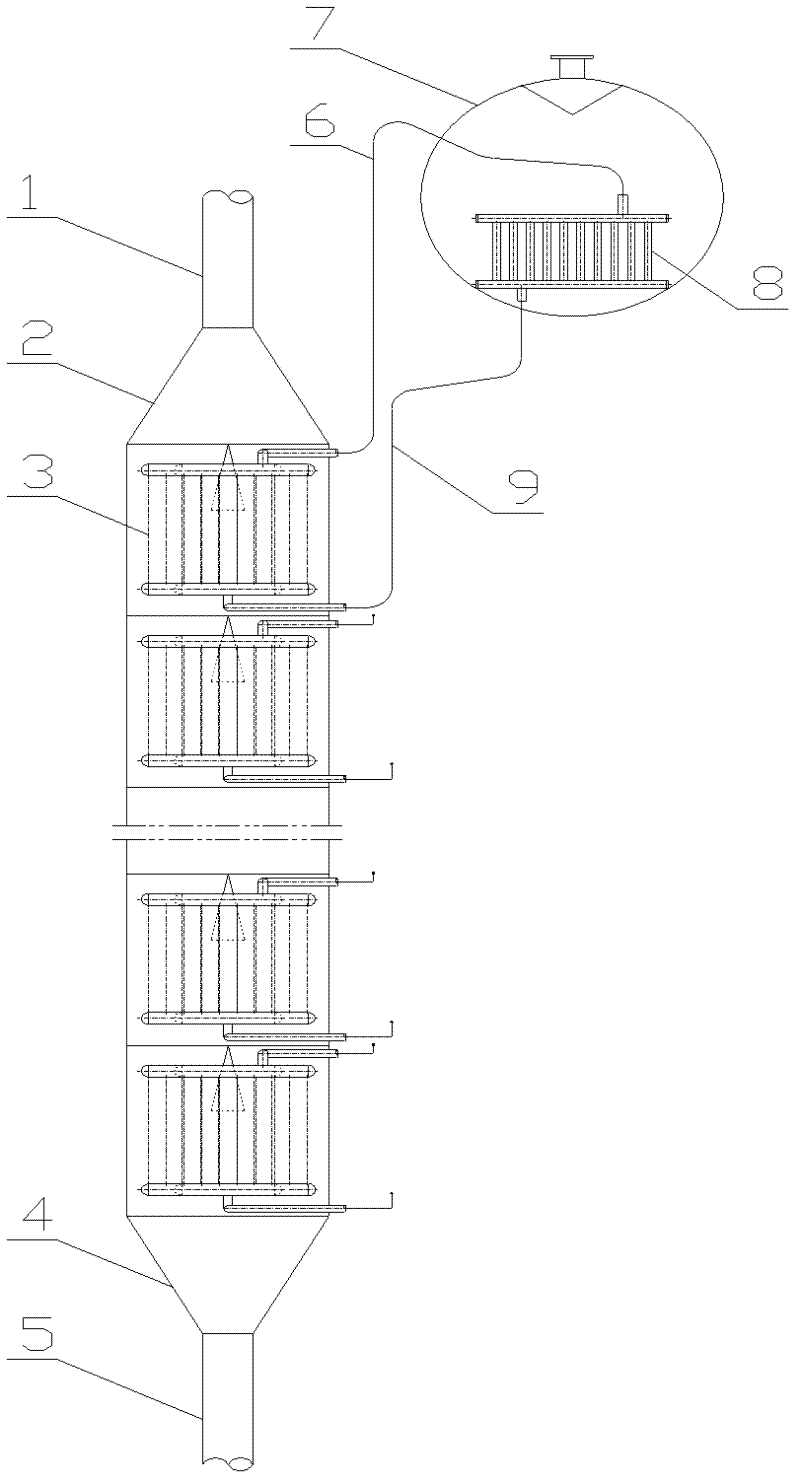

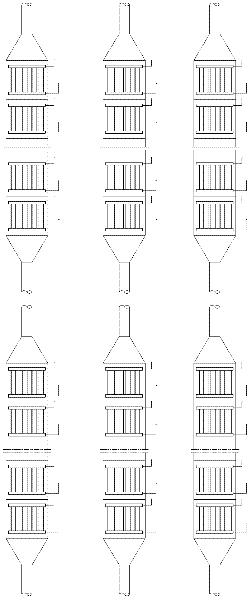

Image

Examples

preparation example Construction

[0038] A kind of preparation technology of methanation catalyst, comprises the following steps:

[0039] Dissolution: the active ingredient nickel compound is configured into a solution;

[0040] Mixing: adding the carrier to the above solution, mixing evenly to obtain a mixture;

[0041] Co-precipitation: add a precipitant to the above mixed solution, stir while adding, so that the mixture is fully mixed, and the pH value is detected at the same time to obtain a precipitate;

[0042] Filtration: filter the above precipitate, discard the filtrate, and wash the filtered solid with water until there is no soluble matter;

[0043] Drying: Dry the above-mentioned washed solid at 25-300°C to obtain a powder sample;

[0044] Molding: add a molding binder to the powdered catalyst after drying, and then extrude or punch into a tablet to obtain a molded catalyst.

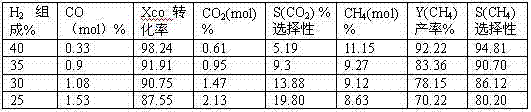

Embodiment 1

[0047] The following substances are all in mass percentage: take 30% of the active ingredient nickel nitrate, 5% of the additive cerium nitrate, and the balance is carrier alumina; prepare the methanation catalyst according to the above process steps, dissolve the nickel nitrate in water and dissolve it in the dissolution process A small amount of ammonium citrate and a small amount of ethylene glycol are added to the mixture, and the precipitant used is ammonia water. When the pH value of the mixture is detected and adjusted to 9.5, it is then left to stand, filtered, washed with water, and dried continuously at 120°C / min. After drying for 4 hours, use acetate fiber accounting for 1% of the weight of the dried powder as a molding binder to extrude the powder or make a tablet.

[0048]

Embodiment 2

[0050] The following various materials are all in mass percentage: take by weighing 60% of active ingredient nickel nitrate, 3wt% of auxiliary agent lanthanum nitrate, and the balance is carrier calcium aluminate; prepare methanation catalyst according to the above-mentioned process steps, nickel nitrate is ethanolized and combined Add a small amount of citric acid and a small amount of urea during the dissolution process: the precipitant used is potassium carbonate, check and adjust the pH value of the mixture to 10.5, then let it stand, filter, wash with water, and then dry continuously at 120oC 2 hours, 400oC air roasting for 5 hours. The powder is extruded or tableted with 1% cellulose acetate molding binder in the weight of the dried powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com