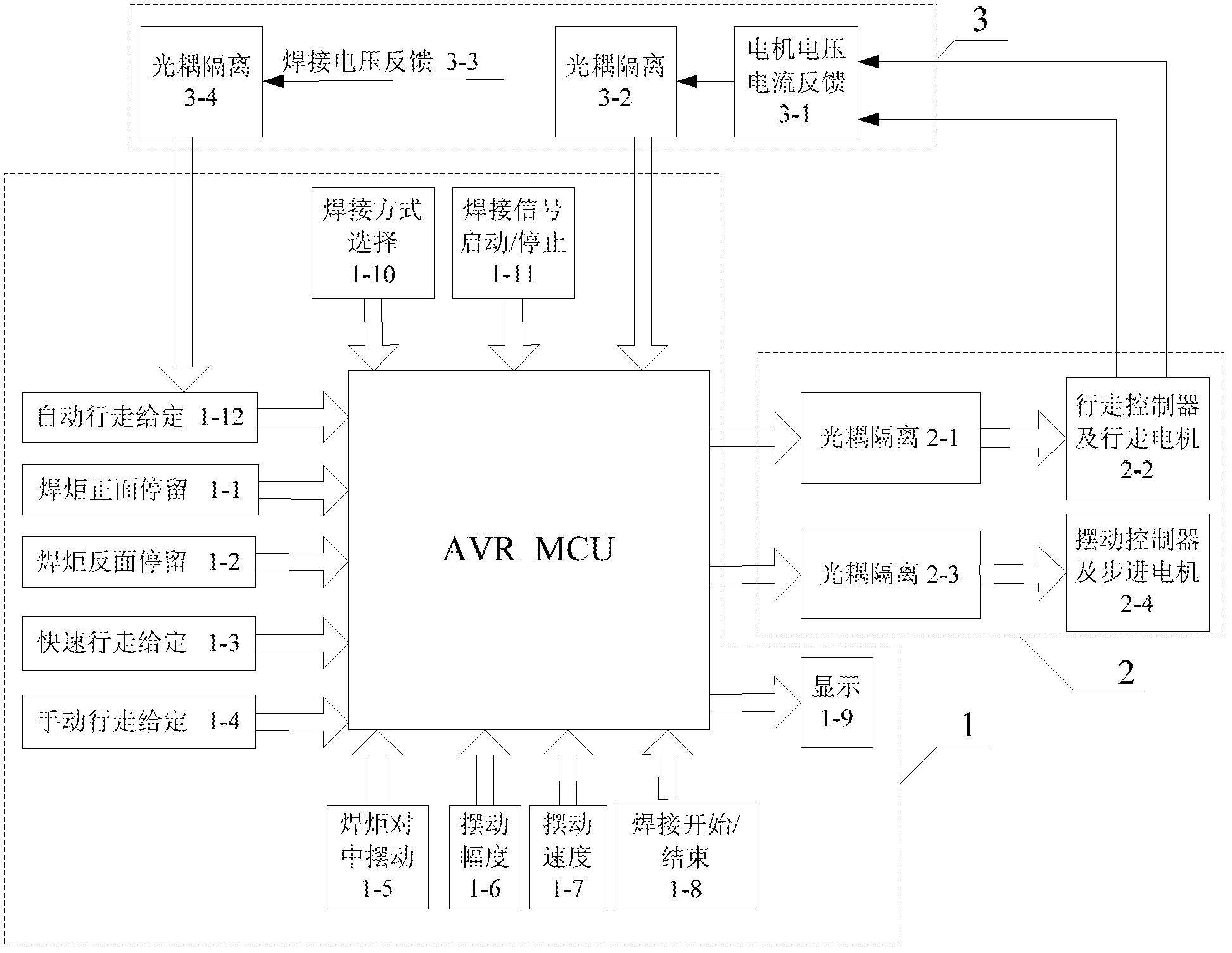

Automatic voltage regulation (AVR) singlechip control-based thick wire electric-gas vertical welding machine and control method

A single-chip microcomputer control, gas-electric vertical welding machine technology, applied in the direction of arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of easy aging, slow dynamic response, low control precision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

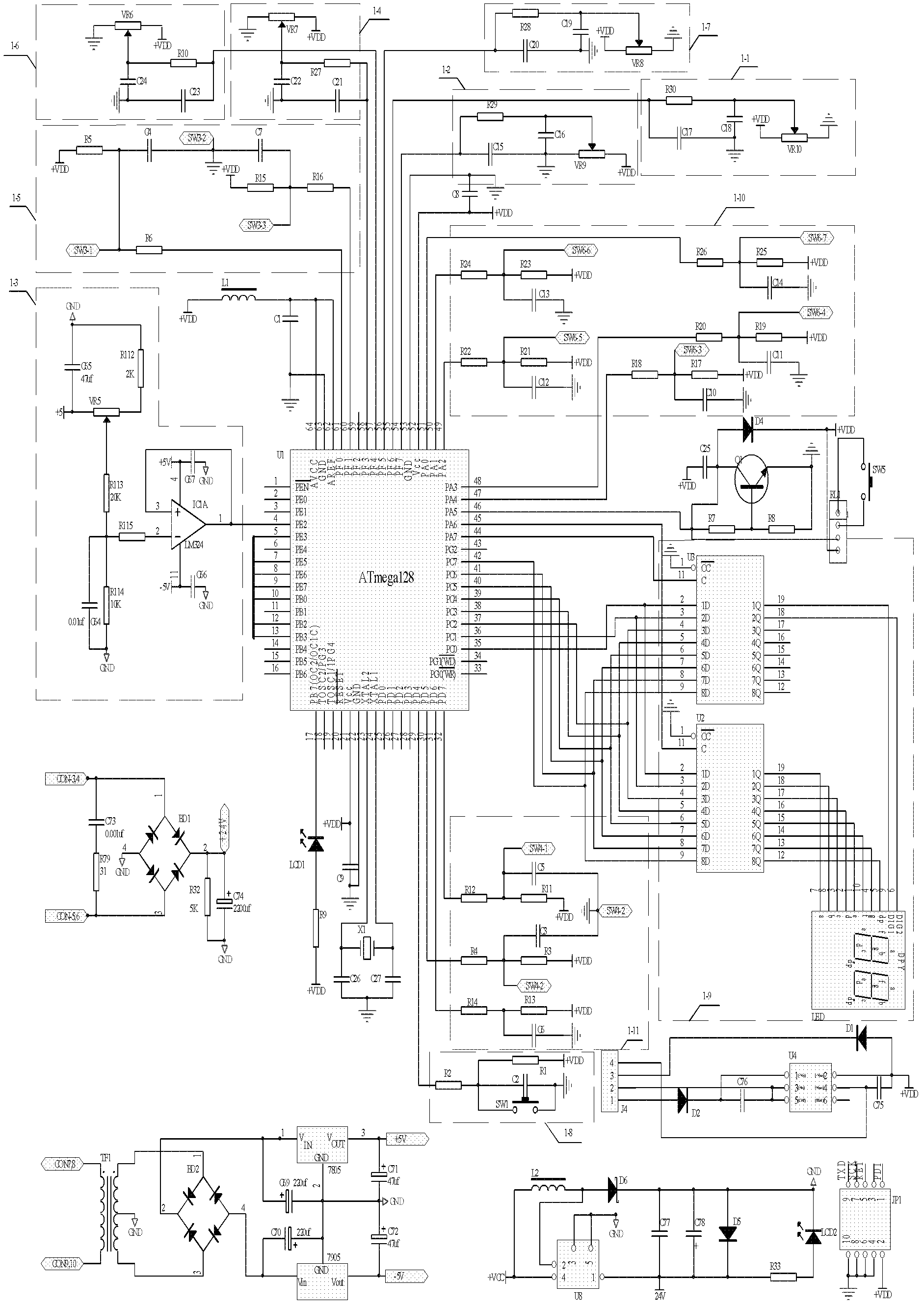

[0055] Such as figure 2 As shown, after the main power is turned on, the chip U1 automatically reads the program into the chip, and the light-emitting diode LCD1 lights up. When the switch UP or DOWM is selected, press the fast travel switch, the circuit starts the fast travel mode, and the given voltage starts from the middle tap of VR5 through R113 and R114, and then through R115, IC1, VR4, R116 and R117 The optocoupler isolation circuit composed of , E1, and C68 enters the No. 4 pin of the AVR single-chip microcomputer, and performs AD conversion inside the single-chip microcomputer, and at the same time generates a PWM pulse signal to drive the DC servo motor. The microcontroller sends the PWM pulse signal and forward and reverse signals to IN1 and IN2 of the TA8429H. When the pressed switch is UP, the input of IN1 is "0" and the input of IN2 is "1", and the motor rotates forward at this time; when the switch is pressed, it is When DOWN, IN1 input is "1" and IN2 input is...

Embodiment 2

[0057] Such as figure 2 As shown, after the main power is turned on, the chip U2 automatically reads the program into the chip, and the light-emitting diode LCD1 lights up. The switch SW2 is placed in the first gear, which is the manual welding mode. First, the climbing speed of the trolley is adjusted by the speed-regulating rheostat VR7, which is input to one end of R27 and then input to the inside of the single-chip microcomputer by R7. After AD conversion, the walking speed of the trolley is adjusted. After pressing the switch SW1, pins 12 and 13 of the single chip microcomputer respectively send PWM pulse signals and motor forward rotation signals to R72 and R73, and then are connected to R71, E8, R68 and R69 through R70, E7, R66 and R67 optocoupler isolation respectively. The IN1, IN2, and EN of the DC servo motor drive chip TA8429, that is, the input of IN1 is "0", and the input of IN2 is "1", and the speed of the DC motor is adjusted at the same time. When the car is...

Embodiment 3

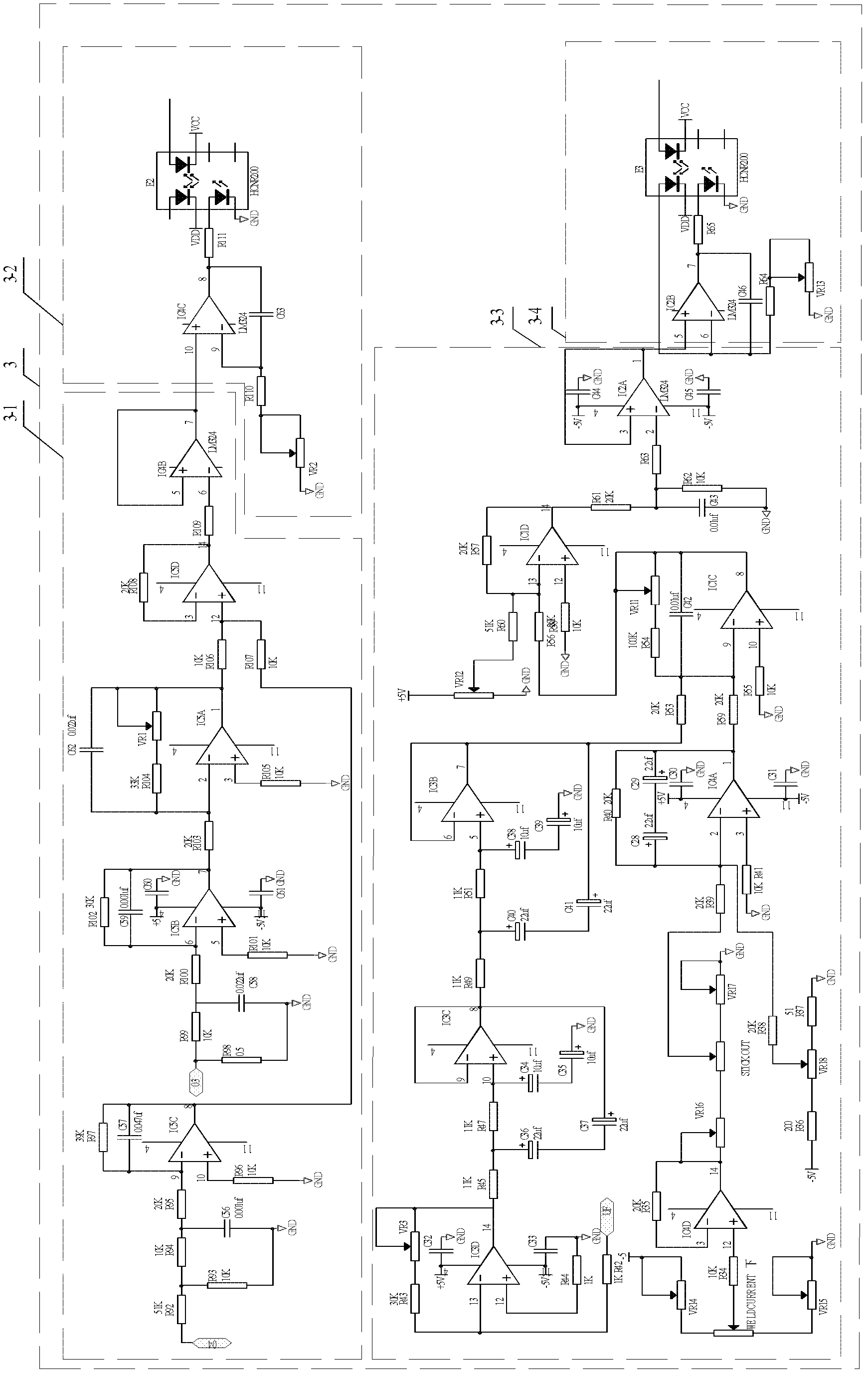

[0060] Such as figure 2 As shown, after the main power is turned on, the chip U1 automatically reads the program into the chip, and the light-emitting diode LCD1 lights up. Put the switch SW2 in the second gear, which is the automatic welding mode. First adjust the rheostat WELDCURRENT, which is a coaxial slider, and at the same time adjust the given welding current. Through the follower composed of R34, R35 and IC4, the output is from pin 14 of IC4. . The center tap of VR16 is connected to one end and then connected to the other end of R35 and pin 14 of IC4. The other end of VR16 is connected with one end of the sliding rheostat STICKOUT. The other end of STICKOUT is connected to one end of VR17, and the middle tap of VR17 is connected to the other end and grounded. To adjust the rheostat STICKOUT is to adjust the dry elongation, and to input one end of R59 into a regulating circuit composed of R39, IC4, R40, R41, C28, C29, VR18, R36, R37, and R38. The welding feedback v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com