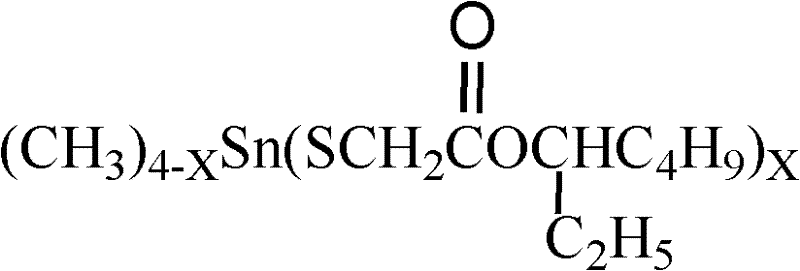

Preparation method of methyltin mercaptide

A technology of methyl tin mercaptide and methyl tin, applied in the direction of tin organic compounds and the like, can solve the problems of high process equipment conditions and energy consumption, insufficient reaction, excess intermediates, etc., and achieves reduction of energy consumption, easy application, The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add the mixture of 90g methyl tin chloride (dimethyl tin dichloride: monomethyl tin trichloride mass ratio=80: 20) (Hangzhou Dongxu Auxiliary Co., Ltd.) in the reactor that connects stirring device, Add 150g of distilled water, start stirring, control the speed at 150 rpm, after it is completely dissolved, raise the temperature to 30°C, slowly add sodium hydroxide until the white turbid liquid pH = 6, after reacting for 3 hours, add 180g of isooctyl thioglycolate (Lianyungang Zuoshi Chemical Co., Ltd.), control the reaction temperature at 40°C, react for 2 hours, stop stirring, cool down, the reaction solution is divided into upper and lower layers, wash the lower reaction solution with water, filter, and put the filtrate in a vacuum of -0.81MPa ~-0.70MPa, 75°C~80°C to distill and remove water to obtain 234.4g of the product methyltin mercaptide, with a yield of 98.5%.

[0034] During the reaction, put the PH test paper at the mouth of the reactor bottle, and the PH tes...

Embodiment 2

[0038] Add the mixture of 95g methyl tin chloride (dimethyl tin dichloride: monomethyl tin trichloride mass ratio=75: 25) (Hangzhou Dongxu Auxiliary Co., Ltd.) in the reactor that connects stirring device, Add 160g of distilled water, start stirring, control the speed at 170 rpm, after the complete dissolution, raise the temperature to 35°C, slowly add calcium hydroxide until the white turbid liquid pH=7, after 4 hours of reaction, add 195g of isooctyl thioglycolate (Lianyungang Zuoshi Chemical Co., Ltd.), control the reaction temperature at 45 ° C, react for 3 hours, stop stirring, cool down, the reaction solution is divided into upper and lower layers, the lower reaction solution is washed, filtered, and the filtrate is vacuumed at -0.80MPa ~-0.74MPa, 70°C~75°C to distill and remove water to obtain 250.9g of the product methyltin mercaptide, with a yield of 98.2%.

[0039] Analysis of product results:

[0040] Tin content: 19.6%; Sulfur content: 12.2%; Specific gravity: 1.1...

Embodiment 3

[0043] Add the mixture of 92g methyl tin chloride (dimethyl tin dichloride: monomethyl tin trichloride mass ratio=85: 15) (Hangzhou Dongxu Auxiliary Co., Ltd.) in the reactor that connects stirring device, Add 140g of distilled water, start stirring, control the rotating speed to be 210 rev / min, after being completely dissolved, heat up to 40°C, slowly add ammonia water until the white turbid liquid pH=8, after reacting for 5 hours, add 185g isooctyl thioglycolate (Lianyungang Zuoshi Chemical Co., Ltd.), control the reaction temperature at 55°C, react for 3.5 hours, stop stirring, cool down, the reaction solution is divided into upper and lower layers, wash the lower layer of reaction solution with water, filter, and put the filtrate at a vacuum degree of -0.80MPa~- 0.71MPa, 75°C-80°C to distill off water to obtain 239.9g of the product methyltin mercaptide, with a yield of 98.0%.

[0044] Analysis of product results:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com