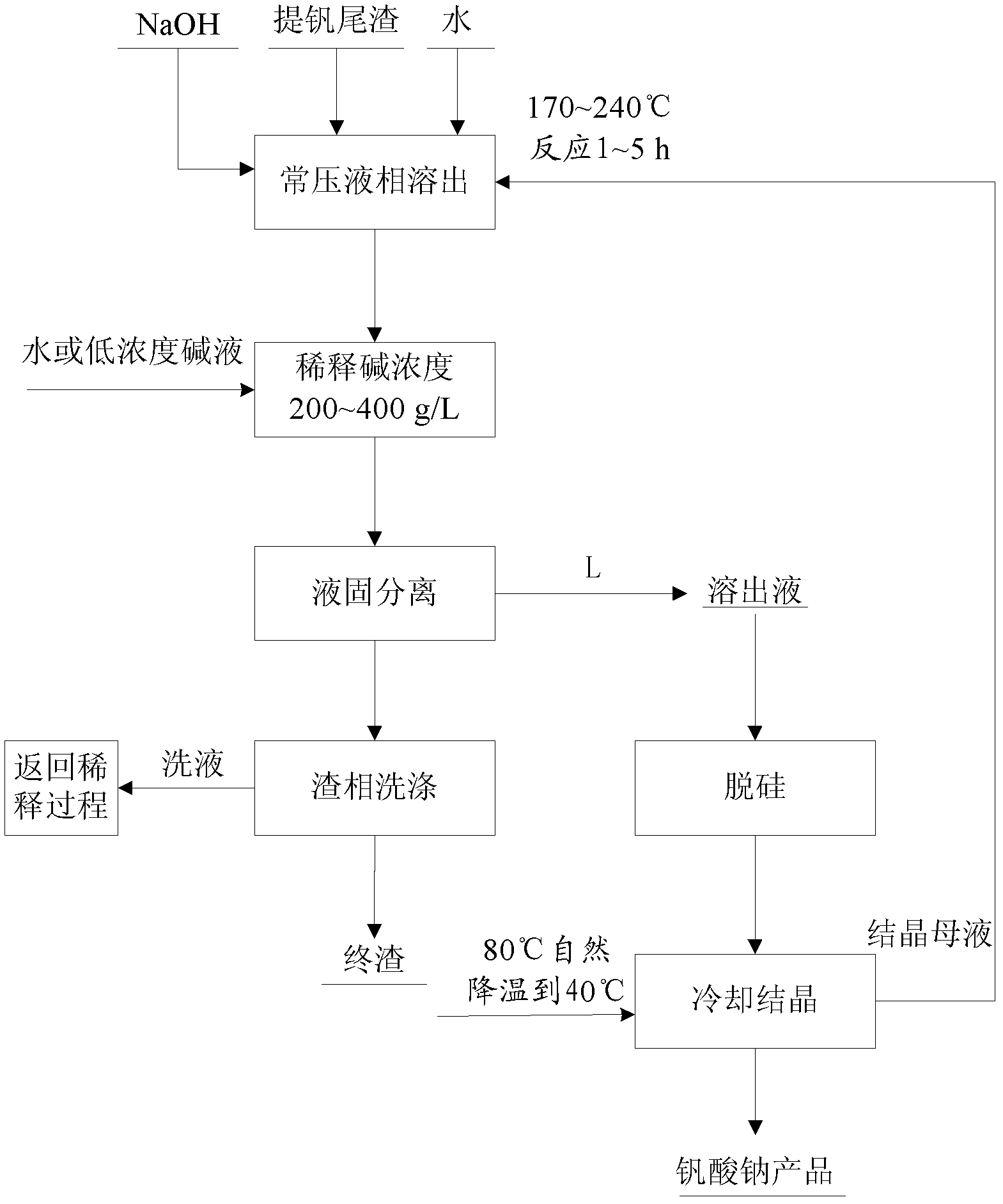

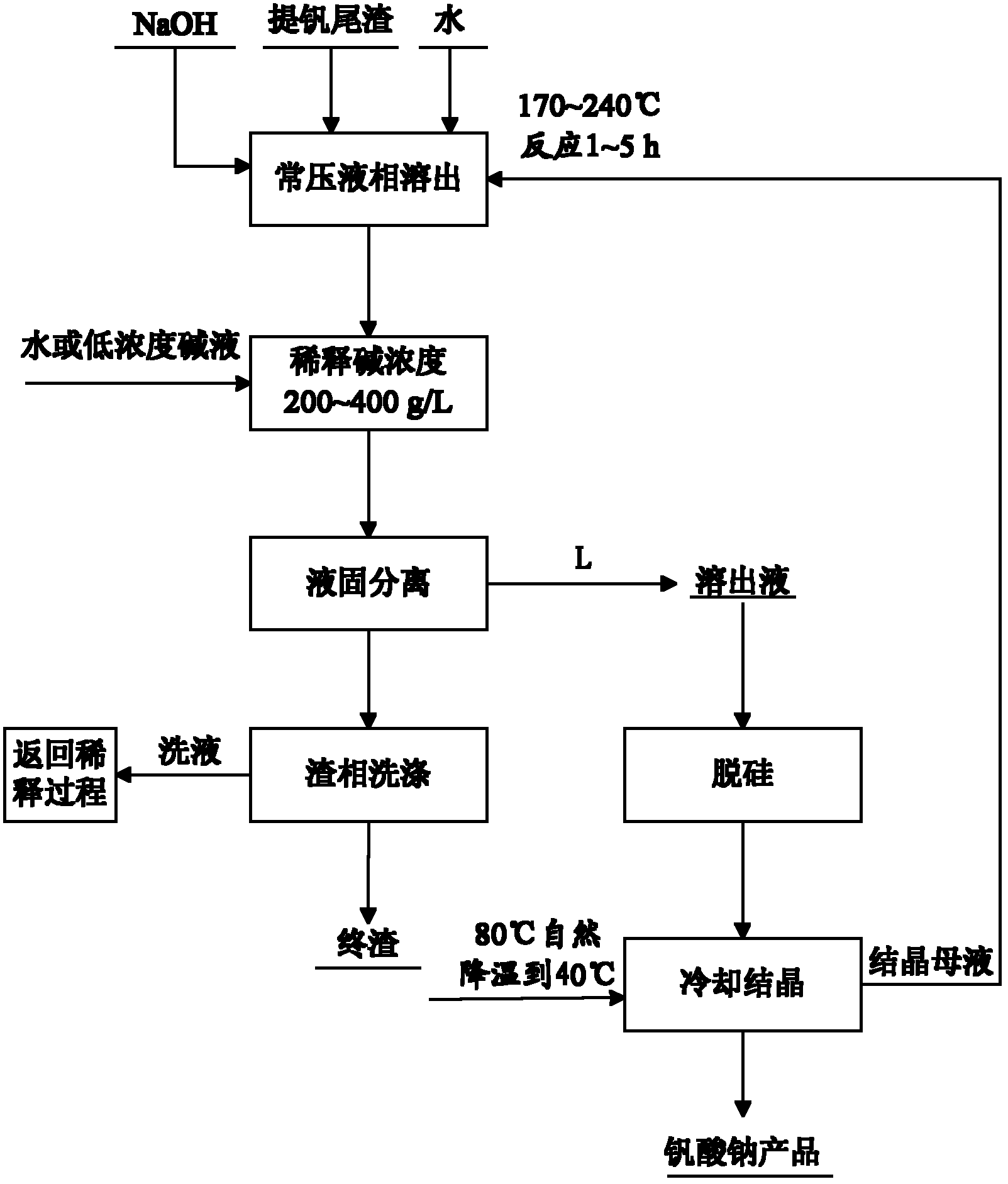

Method for recycling vanadium extraction tailings

A technology for extracting vanadium tailings and vanadium slag, applied in the direction of improving process efficiency, etc., can solve the problem of low vanadium recovery rate, and achieve the effect of high utilization rate of vanadium resources, convenient operation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment uses vanadium extraction tailings containing V 2 o 5 1.23% by weight.

[0033] 1) Ingredients: Put the vanadium extraction tailings screened to 200 mesh into the normal pressure reactor together with water and NaOH, wherein, NaOH 120g, H 2 O 40g, vanadium extraction tailings 40g, and add Na 3 VO 4 12H 2 O30g (to make eluent Na 3 VO 4 Concentration reaches saturation point 60g / L at 40 DEG C, thereby can crystallize and separate the alum of stripping), the weight ratio of NaOH and vanadium extraction tailings is 3: 1; The mass concentration of sodium hydroxide solution is 75wt%;

[0034] 2) Reaction: react the material prepared in step 1) in a normal pressure reactor, control the reaction temperature to 170° C., and the reaction time to 5 hours to obtain a reaction slurry;

[0035] 3) Dilution: after step 2) finishes, dilute the reaction slurry in the reactor with water, be diluted to the sodium hydroxide concentration in the slurry and be 200g / L, o...

Embodiment 2

[0040] This embodiment uses vanadium slag containing V 2 o 5 1.85% by weight.

[0041] 1) Ingredients: add vanadium extraction tailings, circulating fluid, and added NaOH to the atmospheric pressure reactor, wherein the weight ratio of NaOH to vanadium extraction tailings in the reaction system is 4:1; the mass concentration of NaOH solution in the reaction system is 85wt%; the NaOH concentration of the circulating fluid is 700g / L, Na 3 VO 4 Concentration is 45g / L, volume is 200ml; Weigh 40g of vanadium extraction tailings;

[0042] 2) Reaction: react the materials prepared in step 1) in a normal pressure reactor, control the reaction temperature to 220° C., and the reaction time to 3 hours to obtain a reaction slurry;

[0043] 3) Dilution: after step 2) finishes, dilute the reaction slurry in the reactor with the sodium hydroxide solution of 50g / L, be diluted to the slurry sodium hydroxide concentration and be 250g / L, obtain containing sodium hydroxide, vanadium Mixed sl...

Embodiment 3

[0048] This embodiment uses vanadium slag containing V 2 o 5 1.15% by weight.

[0049] 1) Ingredients: add vanadium extraction tailings, circulating liquid and additional NaOH into the atmospheric pressure reactor, wherein the mass ratio of NaOH to vanadium extraction tailings is 5:1; the mass concentration of sodium hydroxide solution in the reaction system It is 80wt%; the alkali concentration of the circulating liquid added is 305g / L, Na 3 VO 4 The concentration is 20.87g / L, and the volume is 520ml; that is, 41.4g of NaOH and 40g of vanadium extraction tailings are weighed;

[0050] 2) Reaction: react the materials prepared in step 1) in a normal pressure reactor, control the reaction temperature to 200° C., and the reaction time to 4 hours to obtain a reaction slurry;

[0051] 3) Dilution: after step 2) ends, water is used to dilute the reaction slurry in the reactor until the concentration of sodium hydroxide in the slurry is 300g / L to obtain sodium hydroxide, sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com