Zirconium alloy for nuclear reactor

A nuclear reactor and zirconium alloy technology, which is applied in the field of zirconium alloy materials, can solve problems such as unsatisfactory requirements, and achieve the effects of improving corrosion resistance, improving safety and efficiency, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to the following examples.

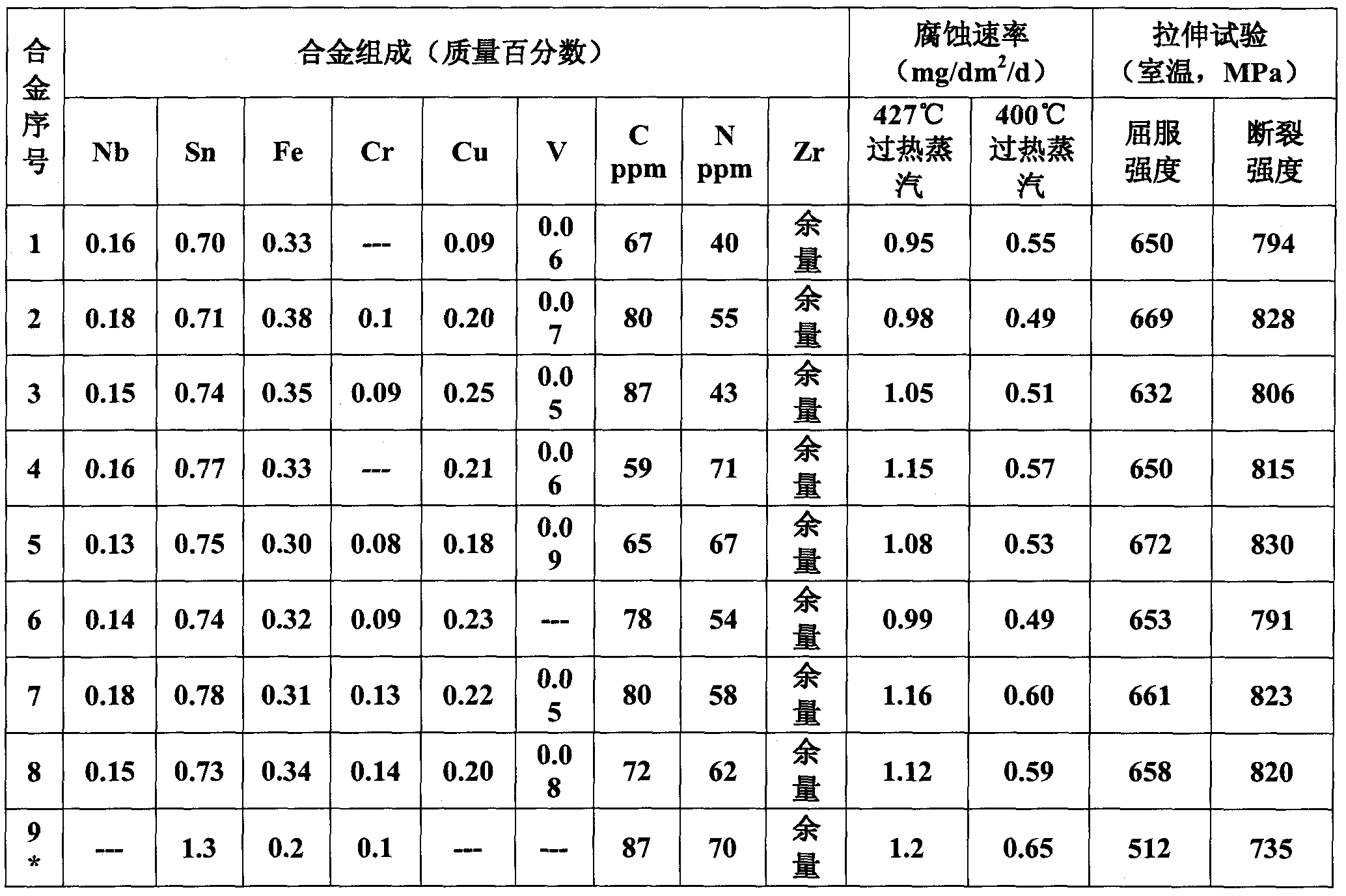

[0012] Use nuclear grade sponge zirconium, Nb, Sn, Fe, Cu, Cr, and V elements in the form of master alloys according to mass percentage, and use vacuum consumable electric arc furnace for multiple melting to make alloy ingots; ingot sampling Chemical composition analysis, the alloy composition is shown in Table 1. Zirconium alloy plates of corresponding composition were produced through forging, quenching, hot rolling, cold rolling, annealing and other processes in the ingot, and prepared into corrosion samples for autoclave corrosion performance test, and some zirconium alloy plates were made into samples for tensile performance test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com