Method for preparing nano platinum/titanium dioxide nanotube electrode by pulse electrodeposition

A technology of pulse electrodeposition and titanium dioxide, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of low current density, uneven deposition layer, high recombination rate of photogenerated carriers, and achieve Pt nanoparticles The effect of small size, excellent photocatalytic performance, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

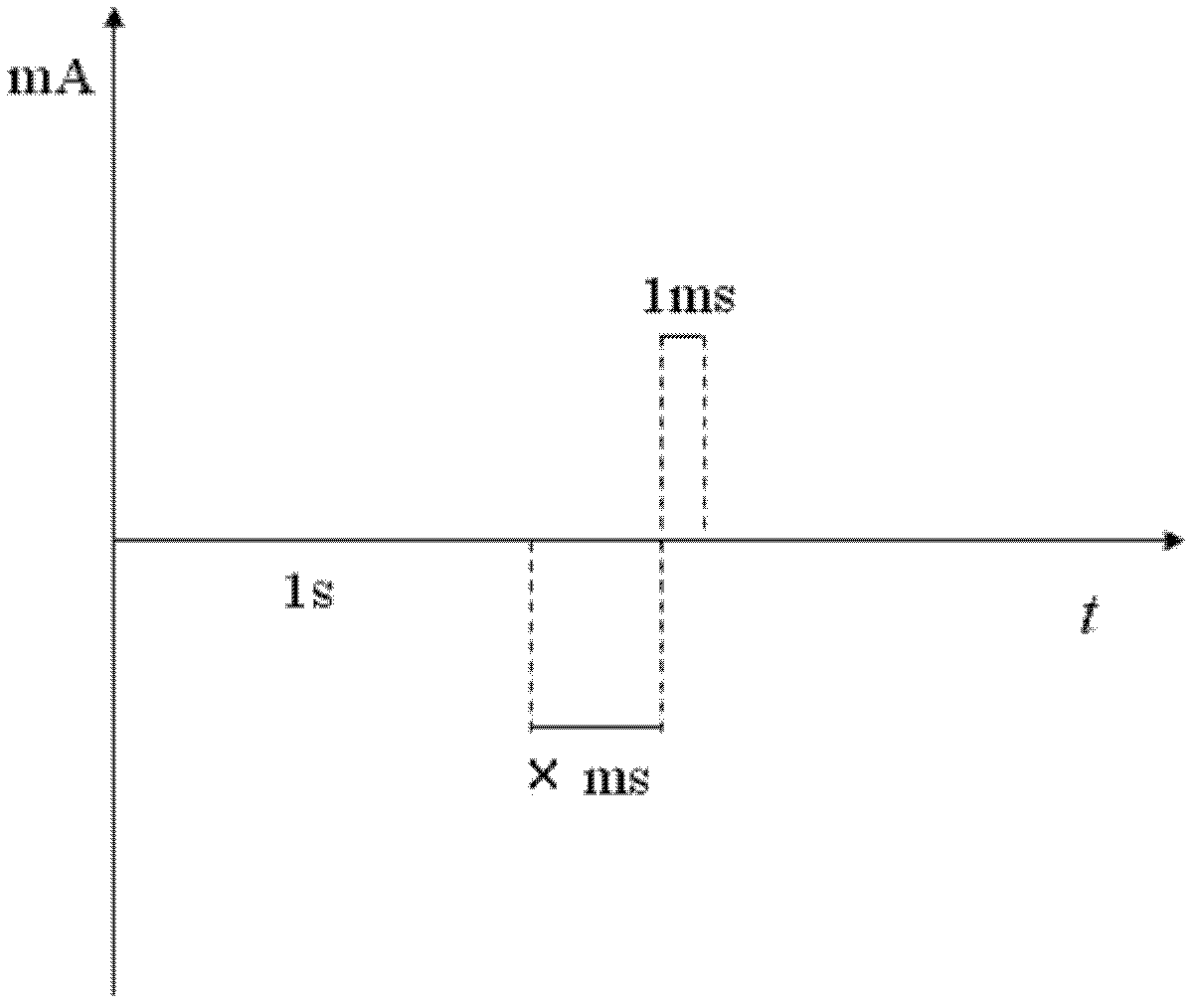

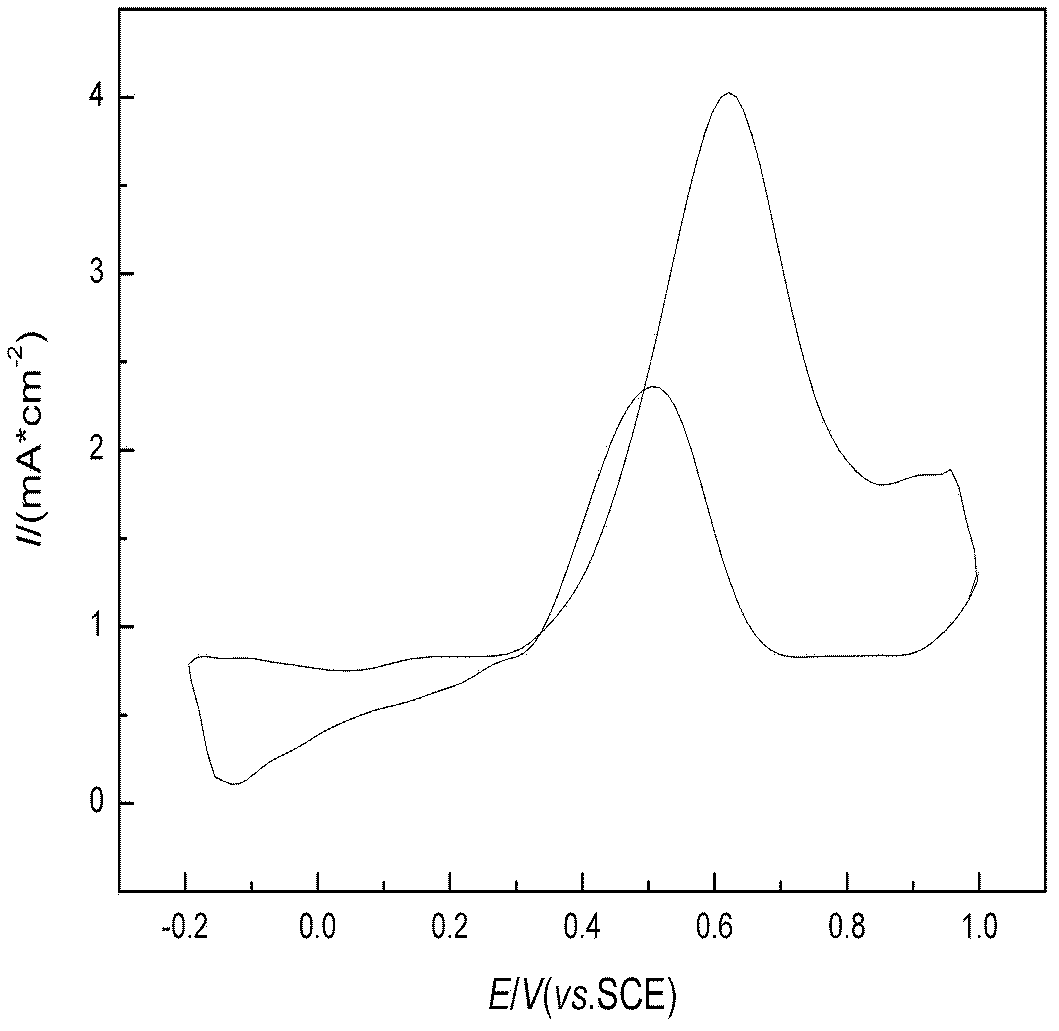

[0022] Example 1. Put 1g / L NH after surface treatment of 1.5mm*1.5mm TA1 titanium 4 HF 2 , 50g / LH 2 The ethylene glycol solution of O was subjected to anodic oxidation at a constant voltage of 10V and a temperature of 20°C for 1h, with constant mechanical stirring during the period. Prepared TiO 2 After the nanotubes are rinsed, they are placed in an electrolyte solution with a composition of 1.0-4.0mM chloroplatinic acid + 0.5M sulfuric acid, and the pulse current density at the cathode is -70mA / cm 2 , the anode pulse current density is 70mA / cm 2 , the cathode pulse conduction time is 10ms, the anode pulse conduction time is 1ms, the off time is 1s, and the electrodeposition time is 15min, that is, the electrode is prepared. The test of the prepared electrode to catalyze methanol is: put the electrode into 0.5M H 2 SO 4 +0.5M CH 3 In the solution of OH, the reference electrode is a saturated calomel electrode, the counter electrode is a platinum electrode, and the work...

example 2

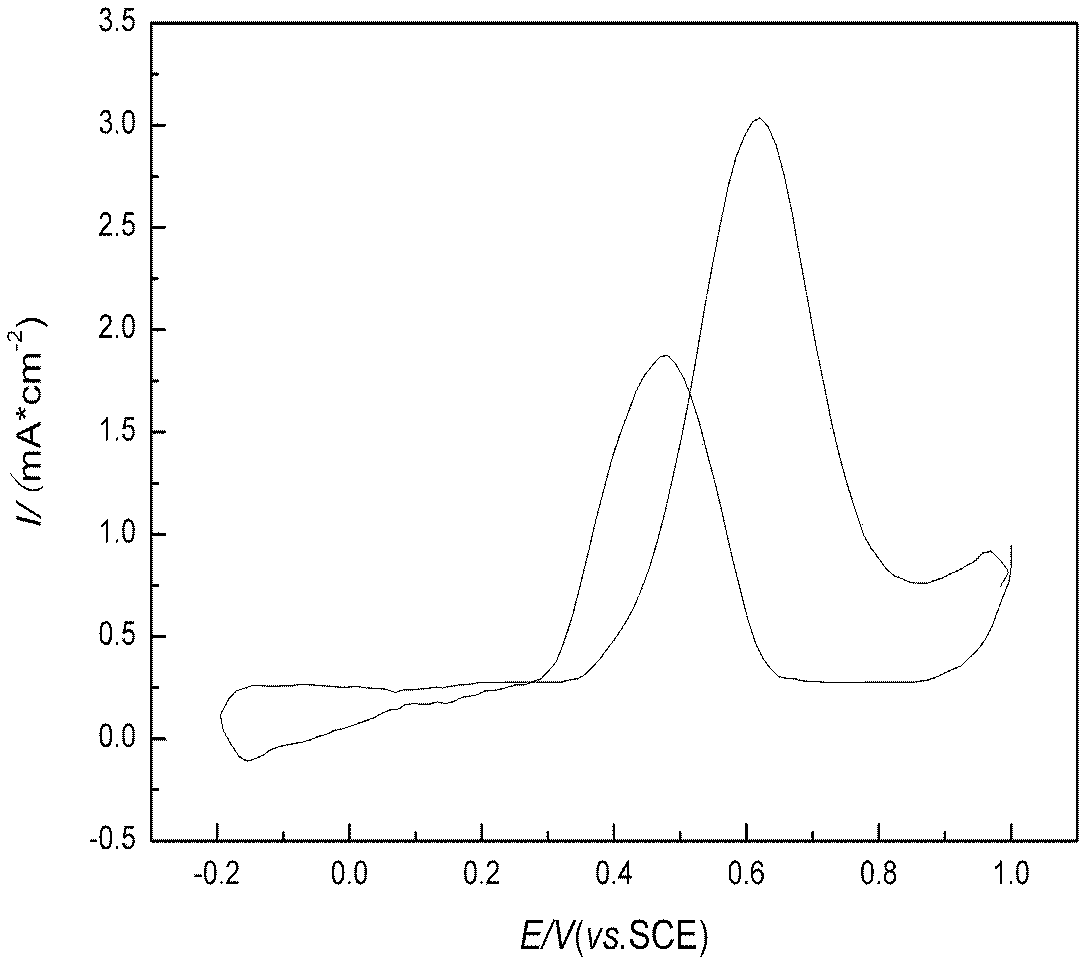

[0023] Example 2. Put 5g / L NH 4 HF 2 , 200g / LH 2 The ethylene glycol solution of O was subjected to anodic oxidation at a constant voltage of 60V and a temperature of 30°C for 6h, with constant mechanical stirring during the period. Prepared TiO 2 After the nanotubes are rinsed, they are placed in an electrolyte solution with a composition of 1.0-4.0mM chloroplatinic acid + 0.5M sulfuric acid, and the pulse current density at the cathode is -10mA / cm 2 , the anode pulse current density is 10mA / cm 2 , the cathode pulse conduction time is 2ms, the anode pulse conduction time is 1ms, the off time is 1s, and the electrodeposition time is 5min, that is, the electrode is prepared. The test of the prepared electrode to catalyze methanol is: put the electrode into 0.5MH 2 SO 4 +0.5M CH 3 In the solution of OH, the reference electrode is a saturated calomel electrode, the counter electrode is a platinum electrode, and the working electrode is Pt-TiO 2 / Ti nanotube electrodes. B...

example 3

[0024] Example 3. Put 3g / L NH 4 HF 2 , 100g / LH 2 The ethylene glycol solution of O was subjected to anodic oxidation at a constant voltage of 30V and a temperature of 10°C for 2h, with constant mechanical stirring during the period. Prepared TiO 2 After the nanotubes are rinsed, they are placed in an electrolyte solution with a composition of 1.0-4.0mM chloroplatinic acid + 0.5M sulfuric acid, and the pulse current density at the cathode is -50mA / cm 2 , the anode pulse current density is 50mA / cm 2 , the cathode pulse conduction time is 6ms, the anode pulse conduction time is 1ms, the off time is 1s, and the electrodeposition time is 25min, that is, the electrode is prepared. The test of the prepared electrode to catalyze methanol is: put the electrode into 0.5M H 2 SO 4 +0.5M CH 3 In the solution of OH, the reference electrode is a saturated calomel electrode, the counter electrode is a platinum electrode, and the working electrode is Pt-TiO 2 nanotube electrodes. Bef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com