Method for determining impurity content in high-titanium slag

A technology of impurity content and high titanium slag, applied in the field of metallurgy and chemical industry, can solve the problems of affecting the accurate determination of the components to be measured, unsuitable for the decomposition measurement of high titanium slag, poor melting effect of high titanium slag, etc., so as to reduce the effect of salt and acid. effect, simple operation, and consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

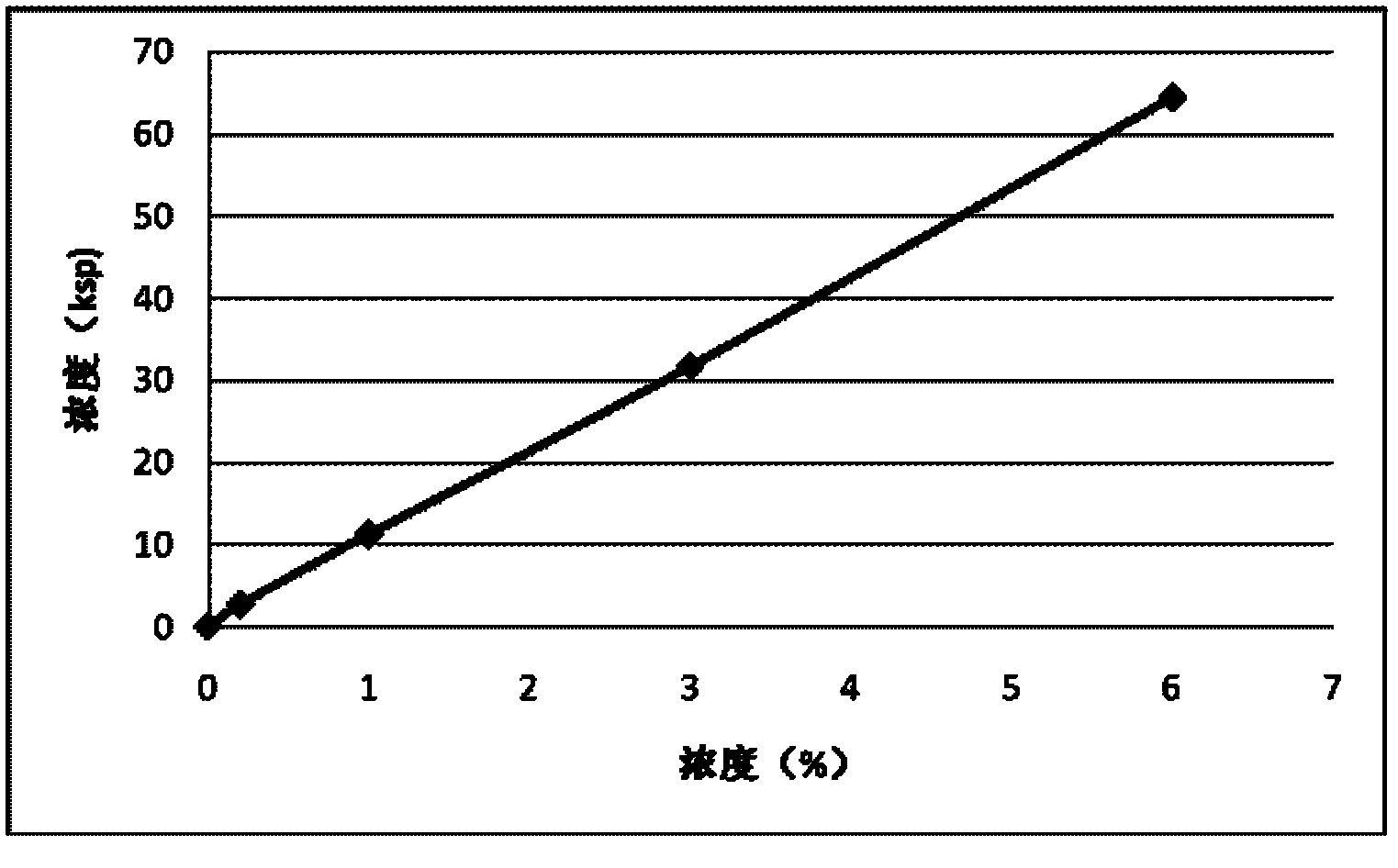

[0026] (1) Melting of the sample to be tested: Weigh 0.2000 g of a sample to be tested and place it in a platinum crucible. The amount of the sample to be tested is generally related to the uniformity, representativeness and subsequent The amount of reagent used in the analysis is directly related to the volume of constant volume dilution. For powder raw material samples, if the samples to be tested are uniformly prepared and representative, for the determination of components with different orders of magnitude, the sample size to be tested is generally said to be 0.1g to 1g. In the determination of inductively coupled plasma spectrometry, usually for the determination of components greater than 0.1% in the sample to be tested, the sample weight is set at 0.1g to 0.5g. For the conventional content of impurities in high titanium slag, iron, silicon dioxide, The determination of dialuminum, calcium oxide, magnesium oxide, manganese oxide, etc. is sufficient to achieve its determ...

Embodiment 2

[0032] (1) Melting of the sample to be tested: Weigh 0.1000 g of a sample to be tested and place it in a platinum crucible; The mixed flux is mixed; after mixing, it is melted in a high-temperature furnace at 950°C for 30 minutes, taken out, and cooled to obtain a frit.

[0033] (2) Leaching and dilution of the frit to be tested: Clean the outer wall of the crucible, add 100mL sulfuric acid (4+96) to a 250mL beaker, heat, leach the frit, and dilute to volume with sulfuric acid (4+96) In a 200mL volumetric flask, pipette 10.00mL to a 100mL volumetric flask to obtain the solution to be tested.

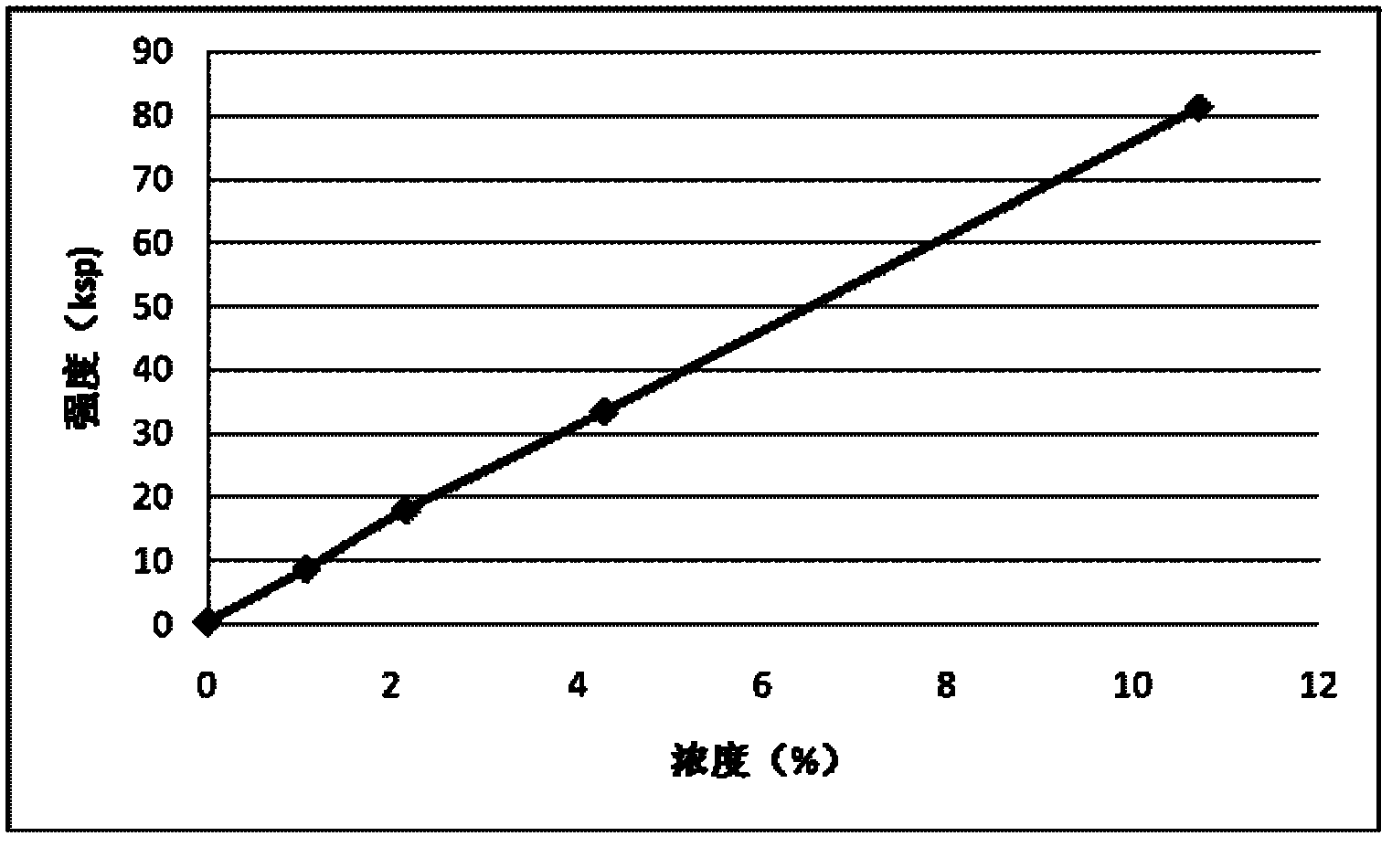

[0034] (3) Preparation of working curve standard solution: take a portion of titanium dioxide reference reagent (more than 99.99% purity) of 90% sample size to be tested, carry out melt leaching under the same conditions as the sample to be tested, and constant volume at In the 200mL volumetric flask, take five parts of 10.00mL and place them in five 100mL volumetric flasks respectively...

Embodiment 3

[0038] (1) Melting of the sample to be tested: Weigh a portion of 0.5000 g of the sample to be tested and place it in a platinum crucible; The mixed flux is mixed; after mixing, it is melted in a high-temperature furnace at 1150°C for 10 minutes, taken out, and cooled to obtain a frit.

[0039] (2) Leaching and dilution of the sample frit: wash the outer wall of the crucible, add 120mL sulfuric acid (6+94) into a 250mL beaker, heat, leach the frit, dilute with sulfuric acid (6+94) to 200mL In the volumetric flask, pipette 10.00mL and dilute it into a 100mL volumetric flask to obtain the solution to be tested.

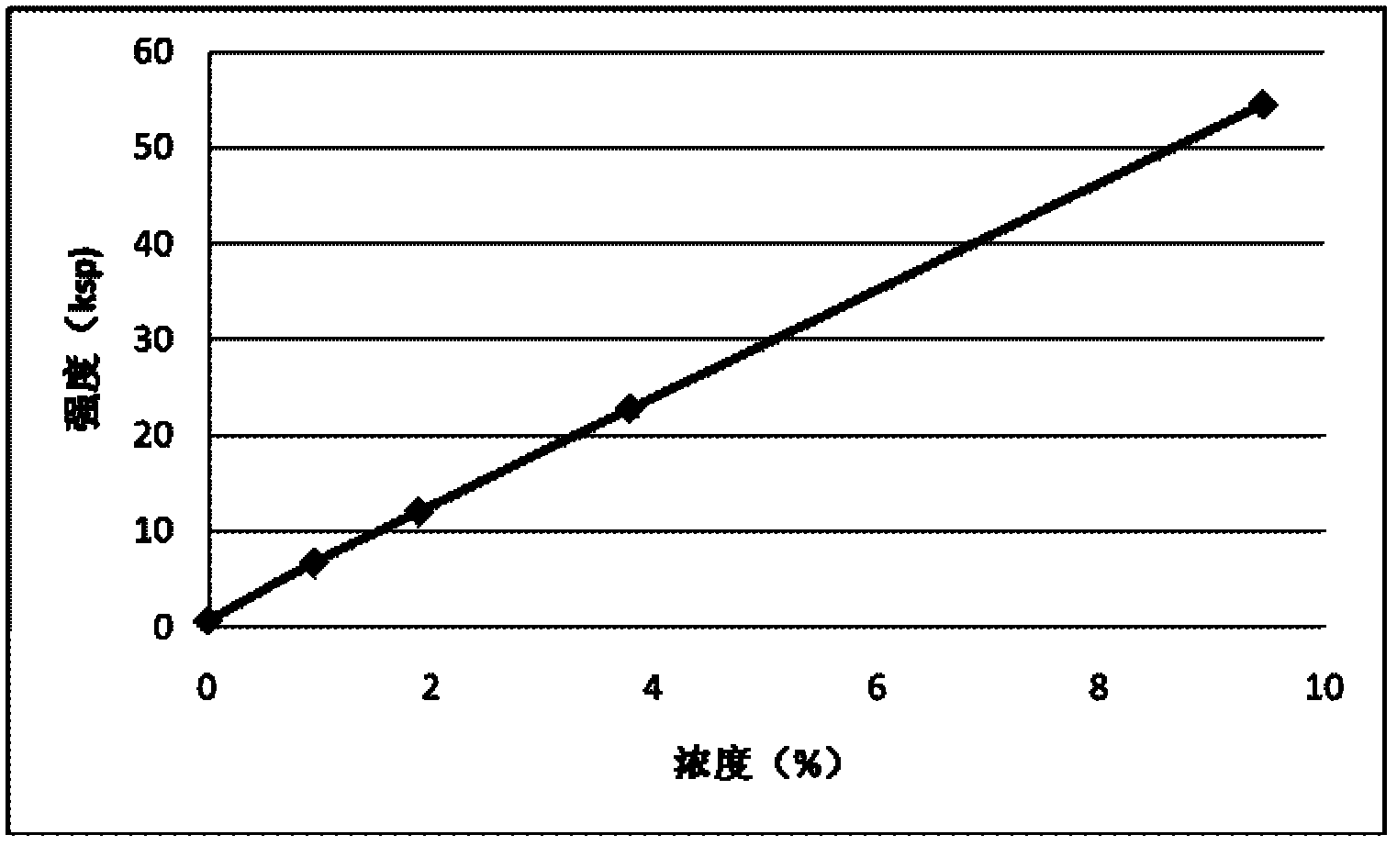

[0040] (3) Preparation of working curve standard solution: Weigh a portion of titanium dioxide reference reagent (above 99.99% purity) with 60% of the sample amount, carry out melt leaching under the same conditions as the sample, and set the volume in a 200mL volumetric flask . Take five portions of 10.00mL and place them in five 100mL volumetric flasks respectively,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com