Composite insulating material and preparation method thereof

A composite insulation and insulator technology, which is applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of high water absorption, poor dielectric stability, insufficient modulus and strength of nylon 1010 insulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

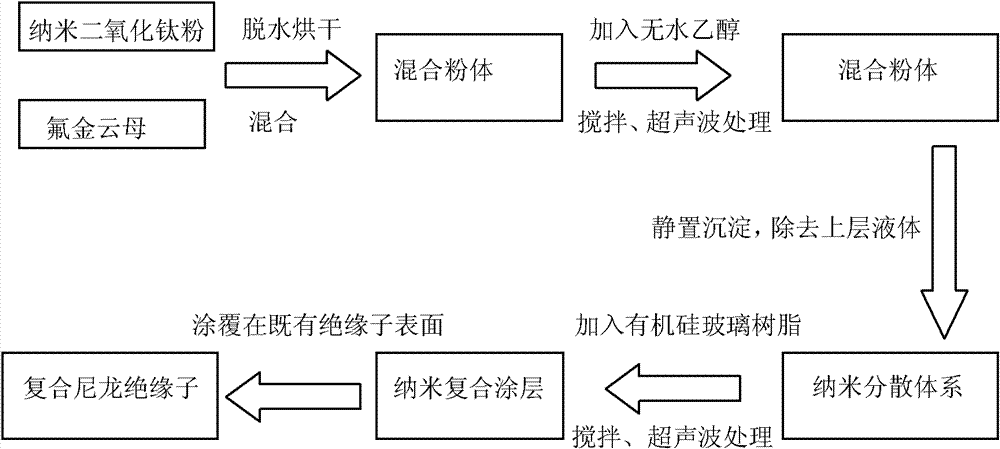

[0032] figure 2 It shows the preparation process of the nylon insulator according to the present invention. The raw materials are mixed according to a certain ratio to prepare a nanocomposite coating material, which is coated on the surface of the existing nylon insulator. The specific preparation process refers to the following examples.

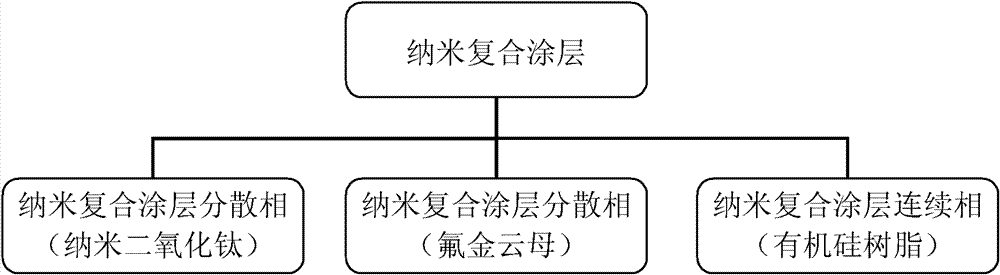

[0033] image 3 Shown according to the schematic diagram of each component of the nanocomposite coating of the present invention, each component is: nano-titanium dioxide (anatase type), organosilicon glass resin (methyltriethoxysilane content is 50%), fluorophlogopite pink.

[0034] In a specific embodiment of the present invention, nano-titanium dioxide (anatase type) is HTTi-type nano-titanium oxide produced by Nanjing Haitai Nanomaterials, with an average particle size of 30-70 nm. The silicone glass resin is MS-1-50 type glass resin produced by Zhonghao Chenguang Chemical Research Institute. It is a methyl silicone resin prepolymer...

Embodiment 1

[0036] First, dry and dehydrate the required nano-titanium dioxide (anatase type) and fluorphlogopite at 110°C for 5 hours, and then add it to an appropriate amount of absolute ethanol. The amount of absolute ethanol is enough to make the mixed powder Just immerse it all, stir it magnetically for 3 hours, and the stirring speed is 150-200 rpm, then use 100W ultrasonic wave to treat the mixed system for 1 hour, remove the gas adsorbed by the nano-powder, let it stand for 24 hours, and wait until the solution system is fully After layering, pour out the absolute ethanol in the upper layer of the solution, then add the silicone glass resin into the dispersion system, stir evenly, and use ultrasonic treatment to disperse the nanoparticles evenly, and obtain a nanocomposite coating. In the nanocomposite coating The mass ratio of organic silicon resin, titanium dioxide and fluorophlogopite is 48%:39%:13%.

[0037] Clean the existing nylon 1010 insulators with alcohol and deionized w...

Embodiment 2

[0041] The preparation process is as in Example 1, the difference is that the mass percentage of silicone glass resin, nano-titanium dioxide and fluorophlogopite is 68%: 24%: 8%, the stirring speed is 200-250 rpm; the vacuum insulation flashover performance test The results show that the vacuum flashover voltage of the nylon insulator coated with the nanocomposite coating has been improved, and the data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com