A Microwave Synthesis Method of ZnO Thin Films with Oriented Nanorod Structure

A zinc oxide film, microwave synthesis technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of poor optoelectronic properties of ZnO nanorod film, unfavorable large-scale industrial production, increase operation complexity, etc., and achieve low cost, crystallization The effect of high degree and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

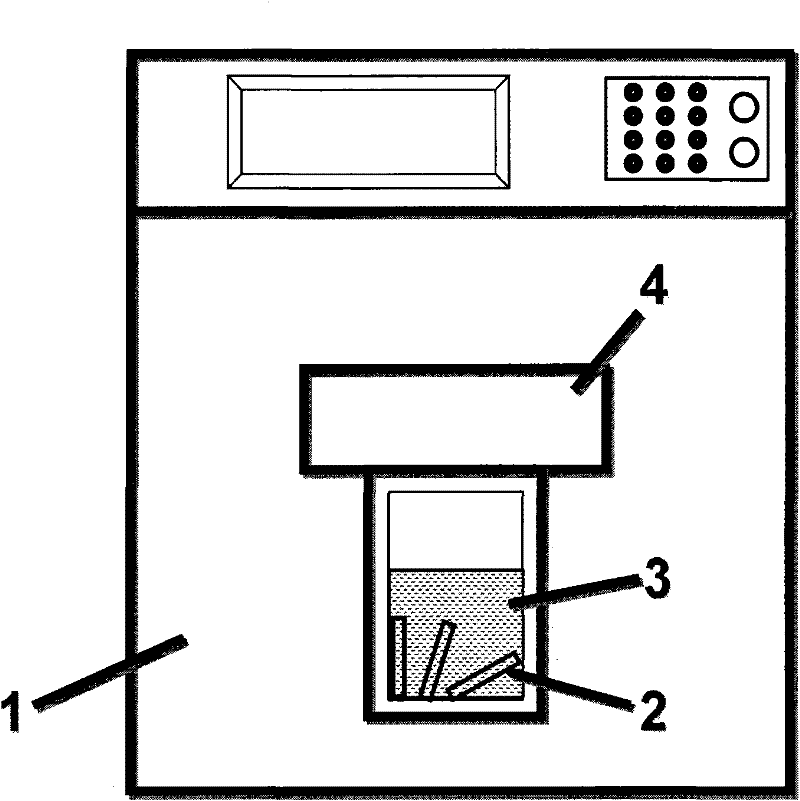

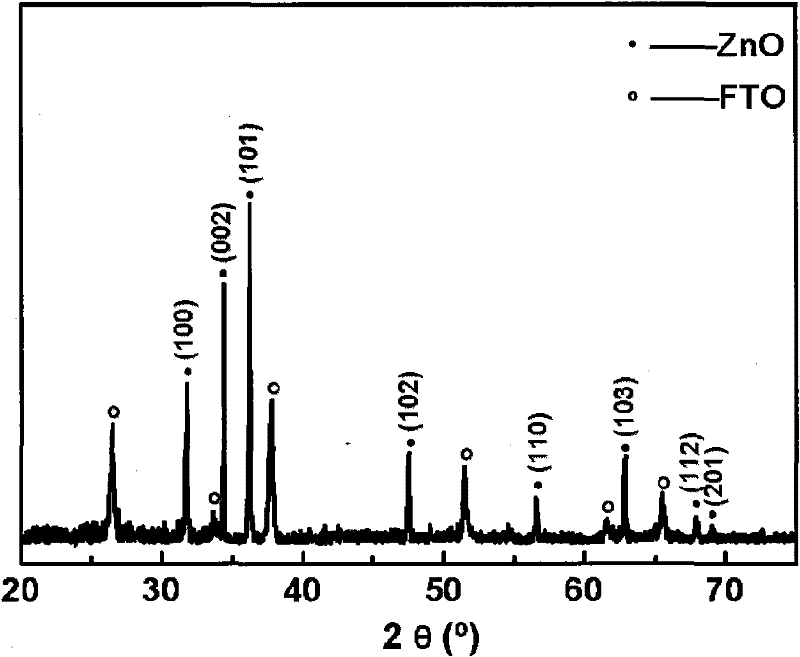

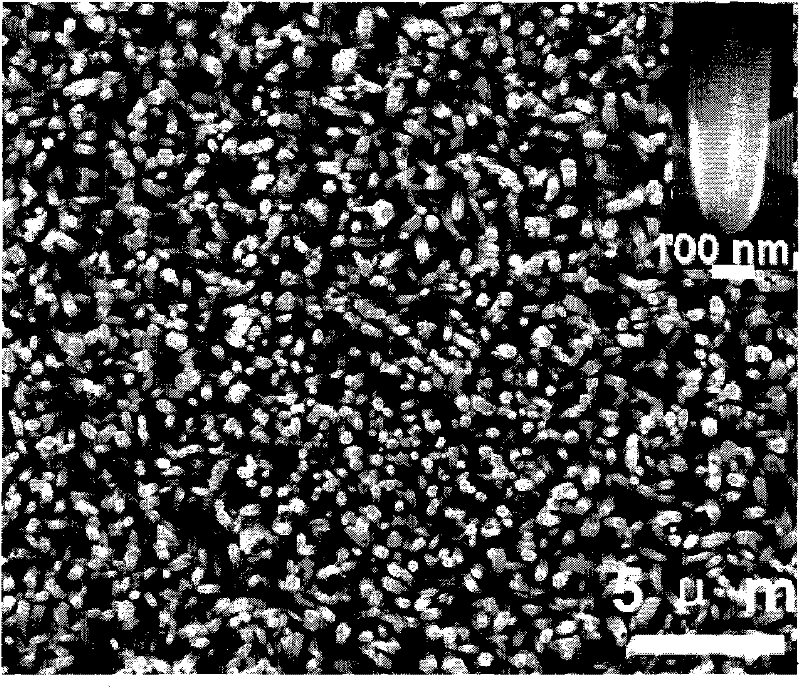

[0029] Embodiment 1: Add analytically pure zinc nitrate hexahydrate into distilled water, and keep stirring to configure Zn 2+Concentration is the transparent solution of 100mM, and the gained solution is denoted as A; Add analytically pure hexamethylenetetramine into distilled water, and keep stirring, is configured into the transparent solution that hexamethylenetetramine concentration is 100mM, and the gained solution is denoted as B: Mix the above prepared A solution and B solution evenly, pour it into the XP1500 microwave digestion container, control the filling degree at 75%, and put the conductive glass substrate inside the XP1500 microwave digestion container, the substrate and the XP1500 microwave digestion container The bottom surface of the digestion vessel is at an angle of 90°, then seal the XP1500 microwave digestion vessel, and put it into the MARS high-throughput closed microwave digestion instrument; select the temperature control mode for reaction, the water h...

Embodiment 2

[0031] Embodiment 2: Add analytically pure zinc sulfate heptahydrate into distilled water, and keep stirring, configure Zn 2+ Concentration is the transparent solution of 50mM, and the gained solution is marked as A; Add the analytically pure hexamethylenetetramine into distilled water, and keep stirring, it is configured into the transparent solution that the hexamethylenetetramine concentration is 50mM, and the gained solution is marked as B: Mix the above prepared A solution and B solution evenly, pour it into the XP1500 microwave digestion container, control the filling degree at 60%, and put the conductive glass substrate inside the XP1500 microwave digestion container, the substrate and the XP1500 microwave digestion container The bottom surface of the digestion vessel is at an angle of 70°, then seal the XP1500 microwave digestion vessel, and put it into the MARS high-throughput closed microwave digestion instrument; select the temperature control mode for the reaction, ...

Embodiment 3

[0032] Embodiment 3: Add analytically pure zinc acetate dihydrate into distilled water, and constantly stir, configure Zn 2+ Concentration is the transparent solution of 150mM, and the gained solution is denoted as A; Add analytically pure hexamethylenetetramine into distilled water, and keep stirring, is configured into the transparent solution that hexamethylenetetramine concentration is 150mM, and the gained solution is denoted as B: Mix the above prepared A solution and B solution evenly, pour it into the XP1500 microwave digestion container, control the filling degree at 90%, and put the plastic substrate inside the XP1500 microwave digestion container, the substrate and the XP1500 microwave digestion container The bottom surface of the container is at an angle of 20°, then seal the XP1500 microwave digestion container, and put it into the MARS high-throughput closed microwave digestion instrument; select the temperature control mode to react, the water heating temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com