A kind of water-based polyurethane and its preparation method, and the water-based ink composition containing this water-based polyurethane and its preparation method

A technology of water-based polyurethane and water-based ink, which can be used in inks, household utensils, applications, etc., and can solve the problems of easy cracking of water-based ink layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

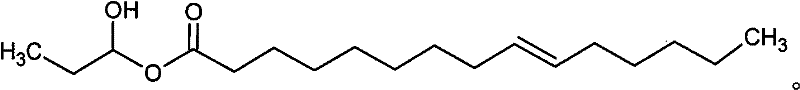

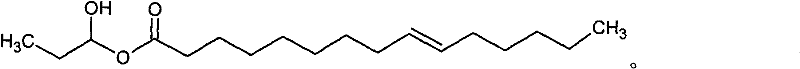

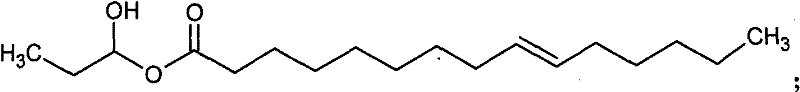

Image

Examples

preparation example Construction

[0018] The present invention also provides a kind of preparation method of above-mentioned waterborne polyurethane, described preparation method is the method for the common synthetic polyurethane of those skilled in the art, comprises the following steps:

[0019] 1) vacuum dehydration of polycarbonate diol and catalyst, adding diisocyanate to react, adding solvent to dilute the reaction system viscosity;

[0020] 2) Adding a hydrophilic chain extender and lignin to the reaction system for chain extension reaction;

[0021] 3) adding a neutralizing agent to the system after the chain extension reaction to carry out the neutralization reaction;

[0022] 4) The solvent is distilled off under reduced pressure to obtain lignin-modified polycarbonate polyurethane.

[0023] The above synthesis method is the acetone method commonly used by those skilled in the art: prepolymer synthesis - viscosity reduction with acetone - chain extension - quaternization - lignin modification - rem...

Embodiment 1

[0059] The present invention provides a synthesis of lignin-modified water-based polyurethane below.

[0060] Add 5500g relative molecular mass in the dry reactor that reflux condenser, stirring tank are housed and be the polycarbonate dihydric alcohol of 2000 and the catalyzer (10% solution of dibutyltin dilaurate) of 20g, add 2500g isophorone again Diisocyanate, reacted at 60°C for 2h, then added 500g of acetone to reduce viscosity, then added 900g of hydrophilic chain extender dimethylolpropionic acid (DMPA) and 600g of sodium lignosulfonate and stirred, reacted for another 4h, and cooled to 40°C, and then under stirring, add 500g of tertiary amine neutralizing agent weighed in step 1 to carry out neutralization, and the neutralized material is equally divided into two parts.

[0061] Part of the acetone was distilled off under reduced pressure to obtain lignin-modified water-based polyurethane powder A11.

[0062] One part was added with 5000 g of distilled water for emul...

Embodiment 2

[0068]The difference from Example 1 is that the water-based ink of the present embodiment does not contain pigment, and the content of sodium lignosulfonate is 1000g to obtain water-based ink A23.

[0069] Adopting a PET sheet with a thickness of 0.125mm, adopting the water-based ink A23 of the present invention to print patterns to form a patterned PET sheet, drying to obtain a PET sheet A24 with a water-based ink pattern layer.

[0070] The in-mold injection molding was carried out according to the conditions of Example 1 to obtain the in-mold decoration A25.

[0071] Prepare 100 pieces of A25 as above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com