A modified organosilicon polymer transmission line anti-icing coating and preparation method thereof

A technology for power transmission lines and polymers, applied in coatings and other directions, can solve problems such as ineffectiveness, and achieve the effects of slowing icing, convenient construction, and solving safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

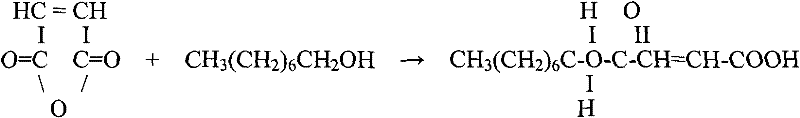

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of a modified organosilicon polymer transmission line anti-icing coating, the method is 45 parts by weight of functional polymer, 50 parts by weight of functional vacuum hollow microspheres coated with fluorosiloxane, and functional additives 1.8 parts by weight, 0.2 parts by weight of defoamer, and 3 parts by weight of polytetrafluoroethylene wax emulsion were stirred and mixed at room temperature for 2 hours to obtain the product.

[0040] Wherein the preparation method of functional polymer comprises the following steps:

[0041] (1) Preparation of emulsion

[0042] Mix 14 parts by weight of cis-octyl grafted with silane monomer, 8 parts by weight of isooctyl acrylate, and 0.2 parts by weight of emulsifier to form emulsion A;

[0043] Mix 14 parts by weight of cis-octyl grafted with silane monomer, 2 parts by weight of isooctyl acrylate, 2 parts by weight of methyl methacrylate, 2 parts by weight of butyl acrylate, and 0.2 parts by weight of emu...

Embodiment 2

[0063] A preparation method of modified organosilicon polymer transmission line anti-icing coating, the method is 40 parts by weight of functional polymer, 55 parts by weight of functional vacuum hollow microspheres coated with fluorosiloxane, and functional auxiliary agent 1 part by weight, 0.3 parts by weight of antifoaming agent, 5 parts by weight of polytetrafluoroethylene wax emulsion, stirred and mixed at room temperature for 1 hour to obtain the product.

[0064] Wherein: the preparation method of functional polymer comprises the following steps:

[0065] (1) Preparation of emulsion

[0066] Mix 10 parts by weight of cis-octyl grafted with silane monomer, 7 parts by weight of isooctyl acrylate, and 0.1 part by weight of commercially available emulsifier sodium alkylbenzenesulfonate to form emulsion A;

[0067] Mix 10 parts by weight of cis-octyl grafted with silane monomer, 2 parts by weight of isooctyl acrylate, 1 part by weight of methyl methacrylate, 1 part by weigh...

Embodiment 3

[0075] A preparation method of modified organosilicon polymer transmission line anti-icing coating, the method is 50 parts by weight of functional polymer, 45 parts by weight of functional vacuum hollow microspheres coated with fluorosiloxane, and functional auxiliary agent 2 parts by weight, 0.1 part by weight of defoamer, and 2 parts by weight of polytetrafluoroethylene wax emulsion were stirred and mixed at room temperature for 3 hours to obtain the product.

[0076] Wherein the preparation method of functional polymer comprises the following steps:

[0077] (1) Preparation of emulsion

[0078] Mix 15 parts by weight of cis-octyl grafted with silane monomer, 10 parts by weight of isooctyl acrylate, and 0.4 parts by weight of emulsifier to form emulsion A;

[0079] Mix 15 parts by weight of cis-octyl grafted with silane monomer, 3 parts by weight of isooctyl acrylate, 2 parts by weight of methyl methacrylate, 2 parts by weight of butyl acrylate, and 0.4 parts by weight of e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com