Solid-phase synthesis method of ziconotide

A technology of solid-phase synthesis of ziconotide, applied in peptide preparation methods, chemical instruments and methods, peptides, etc., can solve the difficulties of separation and purification, low accuracy of disulfide bond connection, low yield, etc. problems, to achieve the effect of easy preparation and purification, the same number of steps, and simplified steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

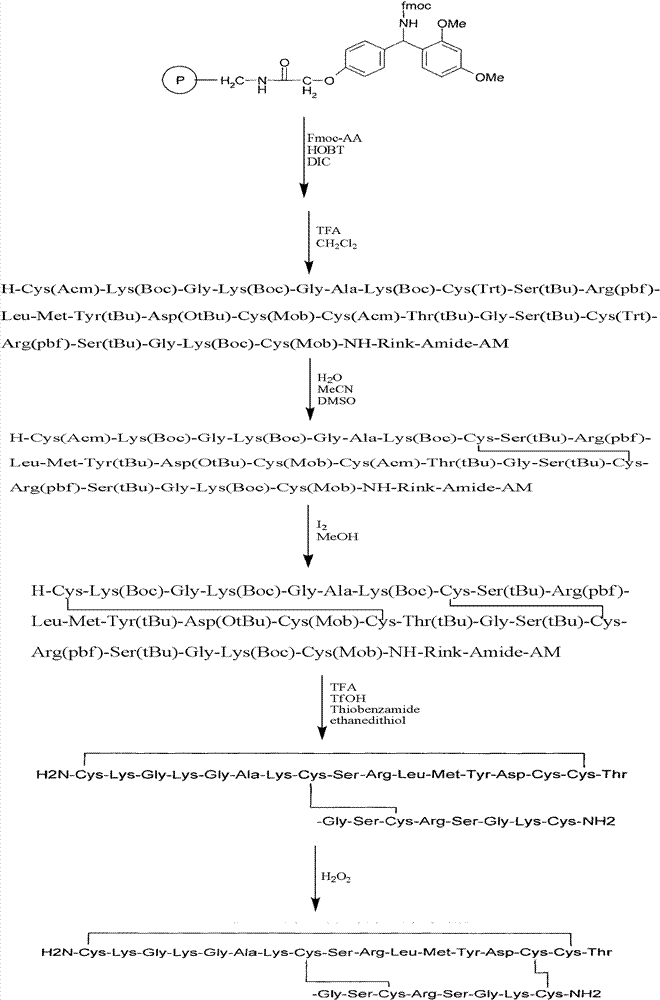

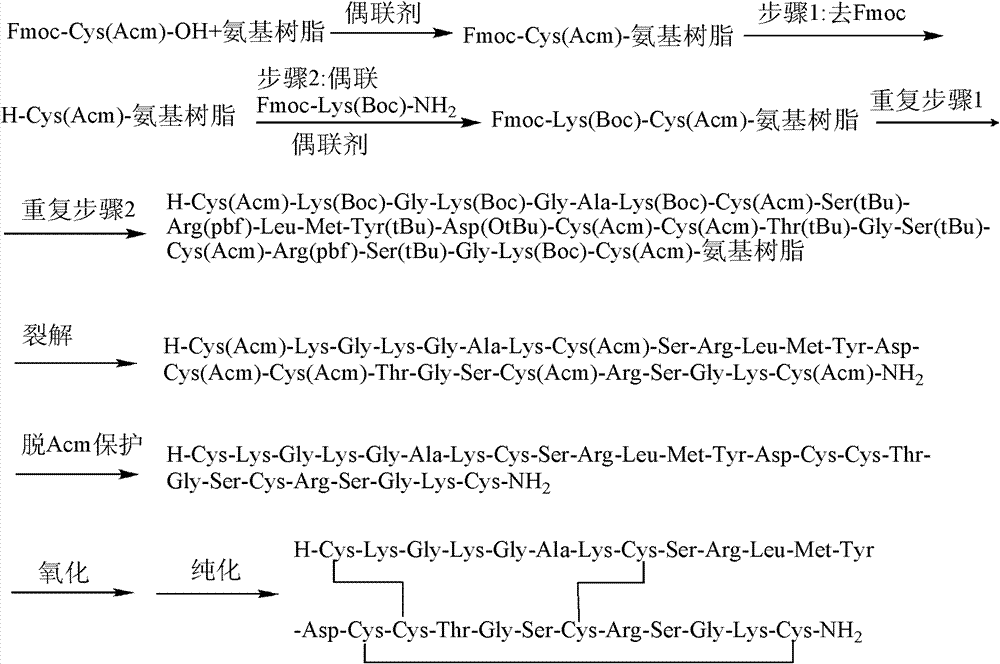

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Preparation of ziconotide linear peptide resin.

[0041] Resin swelling: Weigh 1g of Fmoc-Rink-Amide-MBHA resin into a 20ml BD syringe with sieve plate (common glass peptide reactor can also be used), swell with 3 times the volume of the resin in DCM for 1-4 hours, and wait until the resin swells completely Then, the Fmoc protective group was removed twice with a 20% (v / v) piperidine / DMF solution for 5 min and 20 min, respectively, and washed with DCM and DMF 6 times alternately.

[0042] Amino acid connection: Dissolve 2mmol of Fmoc protected amino acid, 2mmol of HoBt, 2mmol of HBTU, 4mmol of DIPEA in DMF, pre-activate for 5 minutes, then add the swollen resin (resin quality * substitution value = 0.5mmol), shake at room temperature The reaction time is 1.5-2.5 hours. The dosage of each amino acid and condensing agent and the specific reaction time are shown in Table 1. Fmoc removal before connecting the next amino acid. Use piperidine in N, N dimethylformamide ...

Embodiment 2

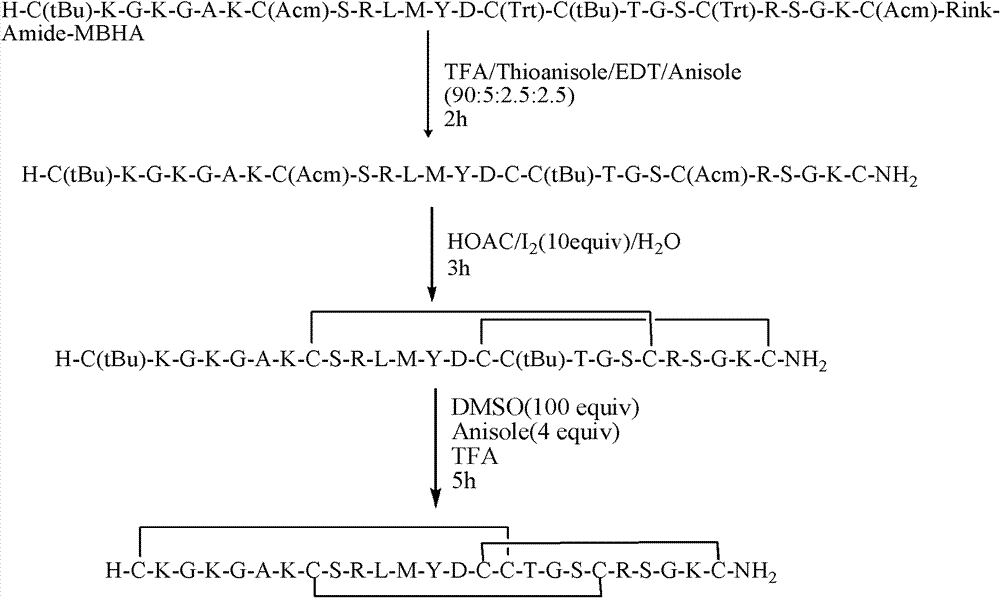

[0050] Example 2: Cutting of the resin and removal of part of the side chain protecting groups.

[0051] Mix trifluoroacetic acid, anisole, dimercaptoethane and anisole in a volume ratio of 90:5:2.5:2.5, or combine trifluoroacetic acid, methanol, water and triisopropylsilane in a volume ratio 88:5:5:2 was mixed, and the linear fully protected peptide resin prepared in Example 1 was added to any of the above two mixtures. The volume of the mixed solution used per 1g of linear fully protected peptide resin was 10 mL, and shake After 2 hours of reaction, the reaction solution was poured into cold ether at -20°C, precipitated, and the white precipitate was collected after centrifugation, and air-dried to obtain a linear crude peptide containing Acm and tBu in the side chain of Cys, weighing 1.4g, and the crude yield was 94%.

Embodiment 3

[0052] Example 3: Formation of Ziconotide Bicyclic Peptide.

[0053] 1.0 g of the linear peptide prepared in Example 2 was dissolved in acetic acid to make the concentration of the linear peptide 0.5 mg / mL, and then 10 times the molar amount of I was added 2 (Dissolved in methanol), stir for 1 hour at room temperature, then add 20% water of the reaction solution volume, check whether the reaction is complete or not by HPLC, after the reaction is complete, add 0.1M ascorbic acid until the solution becomes colorless, the reaction mixture is frozen After drying, washing the precipitate with ether, the crude bicyclic peptide of Cys side chain containing tBu was obtained, weighing 0.91g, and the crude yield of this step was 91%.

[0054] The analytical HPLC detection method is:

[0055] Equipment: C18 analytical column: 4.6×150mm;

[0056] Eluent A: 0.1% (v / v) TFA / H 2 O;

[0057] Eluent B: 0.08% (v / v) TFA / acetonitrile;

[0058] Flow rate: 1ml / min;

[0059] Detection wavelength: 220nm;

[0060]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com