Yttria light-emitting element and preparation method thereof

A light-emitting element, yttrium oxide technology, applied in the direction of chemical instruments and methods, light-emitting materials, etc., can solve the problem of insufficient height of light-emitting films, and achieve the effects of short preparation period, high light intensity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

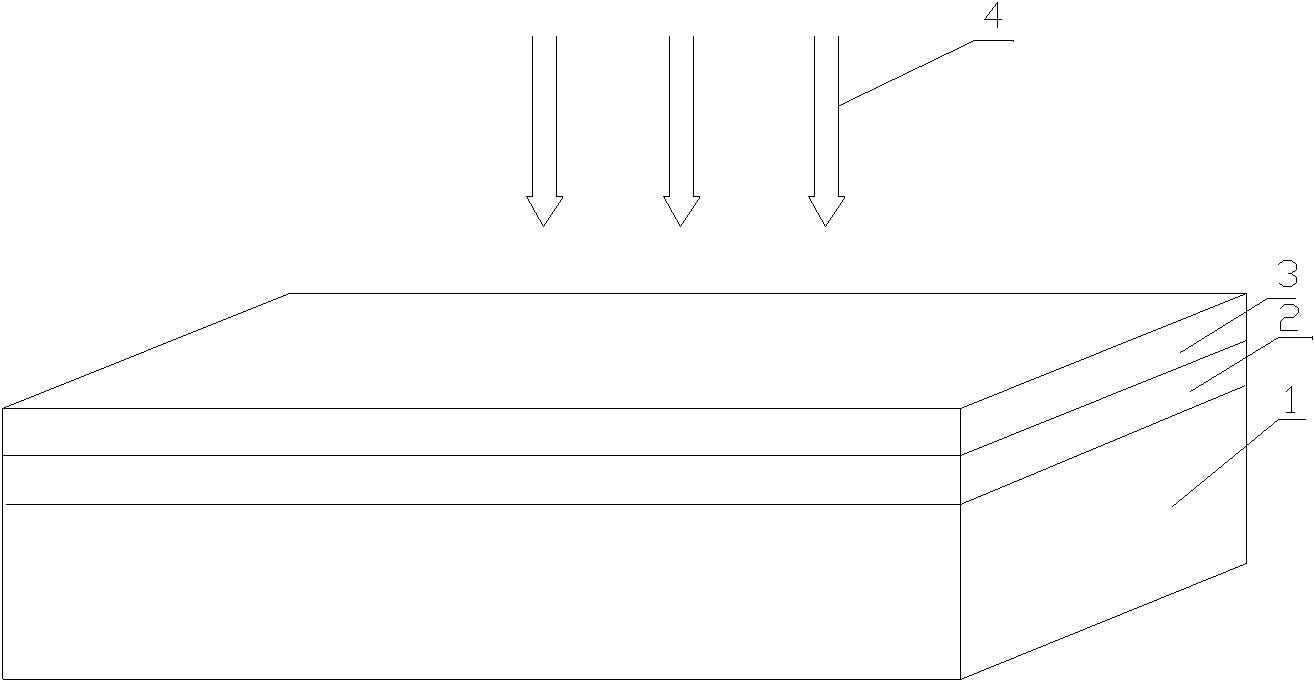

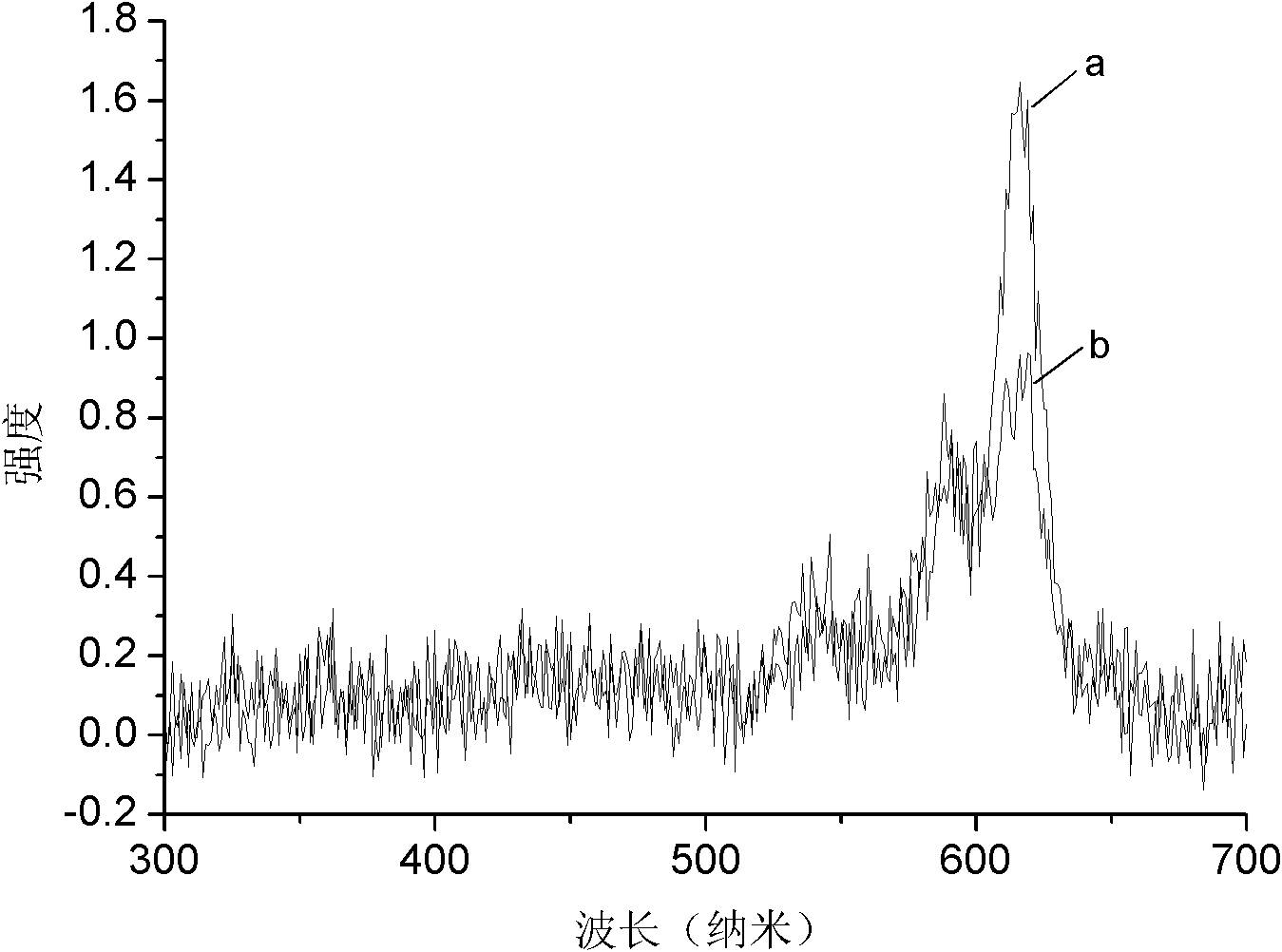

Embodiment 1

[0027] At room temperature, accurately weigh 10.7260g Y 2 o 3 and 0.8798g Eu 2 o 3 Dissolve it in 27mL of hydrochloric acid under the condition of stirring at 60°C, add deionized water to 100mL, and prepare an aqueous solution containing 1mol / L Y and Eu with 5% Eu doping. Measure 8 mL of the above aqueous solution containing 1 mol / L of Y and Eu, add 32 mL of absolute ethanol as a solvent, add 6.1485 g of citric acid and 5 g of polyethylene glycol 6000, and stir for 4 hours in a water bath at 60 ° C to obtain a clear Y , Eu precursor solution. Then the obtained Y and Eu precursor solution was aged in an oven at 70° C. for 60 h to form a uniform Y and Eu mixed colloid. The obtained Y and Eu mixed colloids were spin-coated 6 times. After each coating, the film was dried in an oven at 120°C for 15 minutes, and then the spin-coated film was placed in a temperature-programmed oven at 3°C. / min heating rate to 1000°C and hold for 3 hours to obtain Y with a thickness of 1 μm 2 o...

Embodiment 2

[0031] At room temperature, accurately weigh 37.9180g Y(NO 3 ) 3 ·6H 2 O and 0.4441g Eu(NO 3 )3 ·6H 2 O was dissolved in deionized water, and configured as 100 mL of an aqueous solution containing 1 mol / L of Y and Eu doped with 1% Eu. Measure 20 mL of the above aqueous solution containing 1 mol / L Y and Eu, add 20 mL of absolute ethanol as a solvent, add 15.3712 g of citric acid and 5 g of polyethylene glycol 20000, and stir for 4 hours in a water bath at 60 ° C to obtain a clear Y , Eu precursor solution. Then the obtained Y and Eu precursor solutions were aged in an oven at 80° C. for 56 hours to form a uniform Y and Eu mixed colloid. The obtained Y and Eu colloids were spin-coated three times, and after each coating, the film was dried in an oven at 150° C. for 5 minutes. The spin-coated film was placed in a temperature-programmed furnace to raise the temperature to 700°C at a rate of 1°C / min and hold it for 3 hours to obtain a Y film with a thickness of 100 μm. 2 o ...

Embodiment 3

[0034] Y was prepared by magnetron sputtering 2 o 3 :Eu luminescent film, using electron beam evaporation equipment in Y 2 o 3 : Deposit a metal palladium layer with a thickness of 1nm on the surface of the Eu luminescent film, and then place it in a vacuum of 1×10 -5 Annealing at 200°C for 180min in a vacuum environment of Pa, and then cooling to room temperature to obtain a yttrium oxide light-emitting element with a palladium layer having a metal micro-nano structure formed on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com