Polycrystalline silicon ingot and manufacturing method thereof as well as solar cell

A technology of polycrystalline silicon ingots and manufacturing methods, which is applied to the growth of polycrystalline materials, chemical instruments and methods, circuits, etc., can solve the problems of high impurity content and defect density, affecting the photoelectric conversion efficiency of solar cells, and low photoelectric conversion efficiency. Effect of reducing impurity content and improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

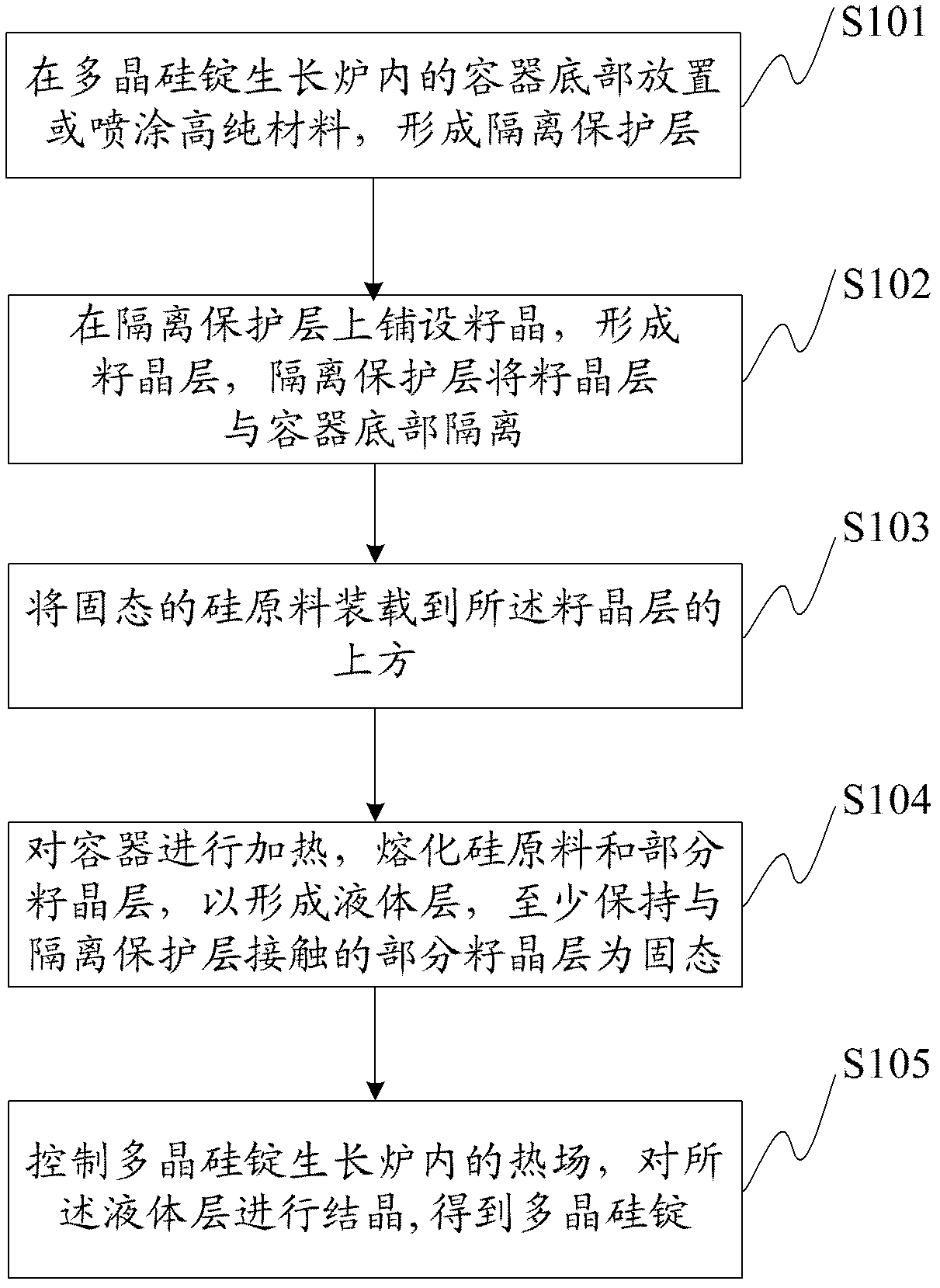

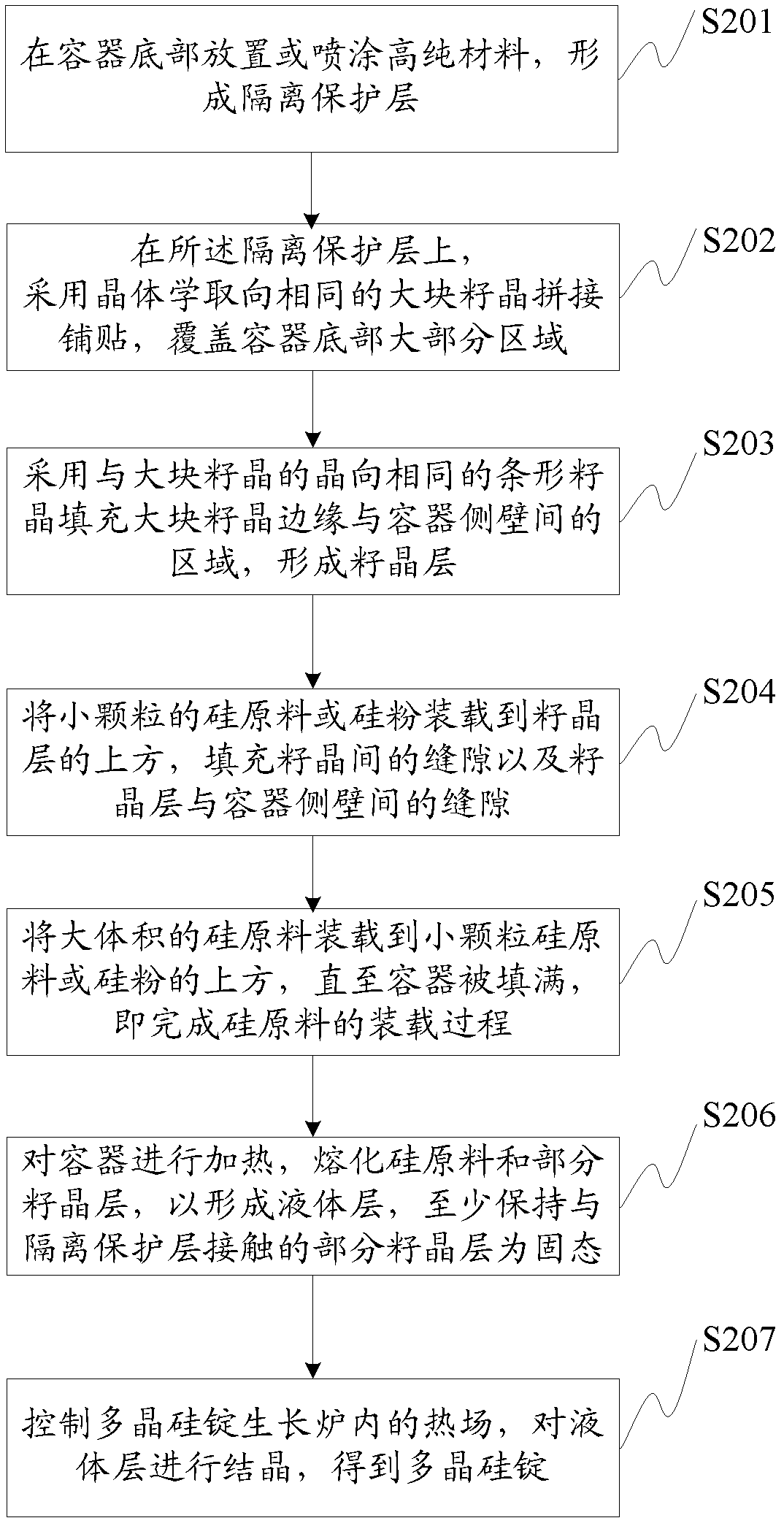

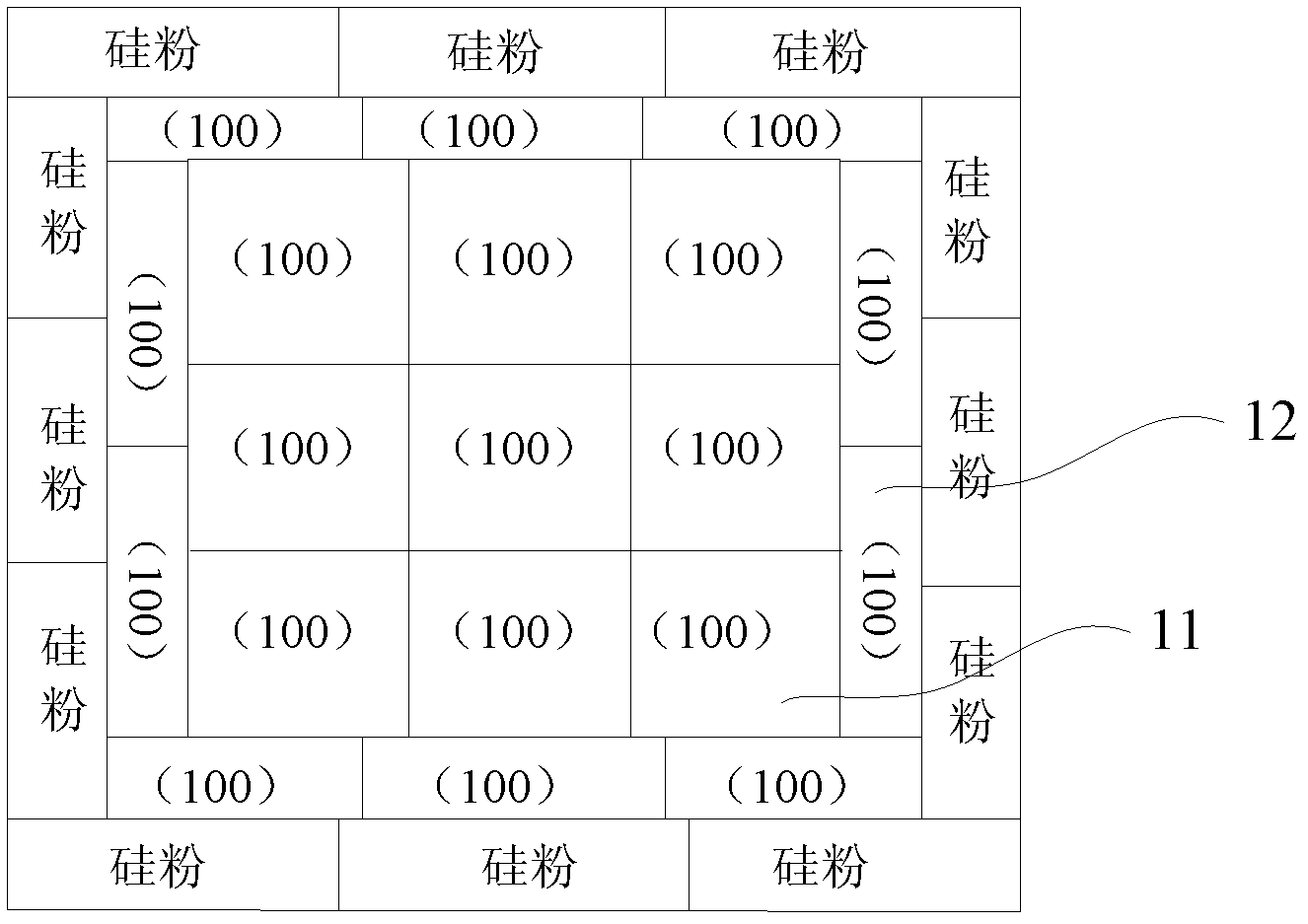

[0052]As mentioned in the background technology section, the photoelectric conversion efficiency of solar cells made of polycrystalline silicon ingots produced by the DSS method of the prior art is low. Specifically, oxygen and carbon are the main light element impurities in cast polycrystalline silicon ingots, especially the concentration of carbon is higher than that in Czochralski single crystal silicon, and there are also impurities such as metal elements, nitrogen, and hydrogen. It will adversely affect the performance of polycrystalline silicon materials and solar cells; on the other hand, because the cast polycrystalline silicon ingot has high density of grain boundaries, dislocations and micro-defects, these defects become the recombination centers of minority carriers in silicon materials, The rapid recombination of charge carriers leads to low minority carrier lifetime, and, because the orientation between grains is random, it is difficult to use chemical methods to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com