Graphene-cadmium selenide nanobelt heterojunction, battery, component and preparation method

A cadmium selenide and nanoribbon technology, applied in the field of nanomaterial-based solar cells, can solve problems such as high cost, material purity and preparation process limitations, and large-scale popularization and application constraints, and achieve simple manufacturing process, simple structure, and low cost. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Ordinary glass slides are ultrasonically cleaned with deionized water and absolute ethanol, and dried for later use; cadmium selenide nanobelts prepared by chemical vapor deposition are dissolved in ethanol to form ethanol suspensions of cadmium selenide nanobelts for later use ; Graphene film on copper foil prepared by chemical vapor deposition, using HCl and FeCl in conventional technology 3 .6H 2 O (molar ratio 1:1) mixed solution, after dissolving the copper foil, the graphene film floats on the surface of the solution, and is repeatedly transferred to clean deionized water to remove excess ions, and finally the clean graphene film Float on the surface of deionized water and set aside.

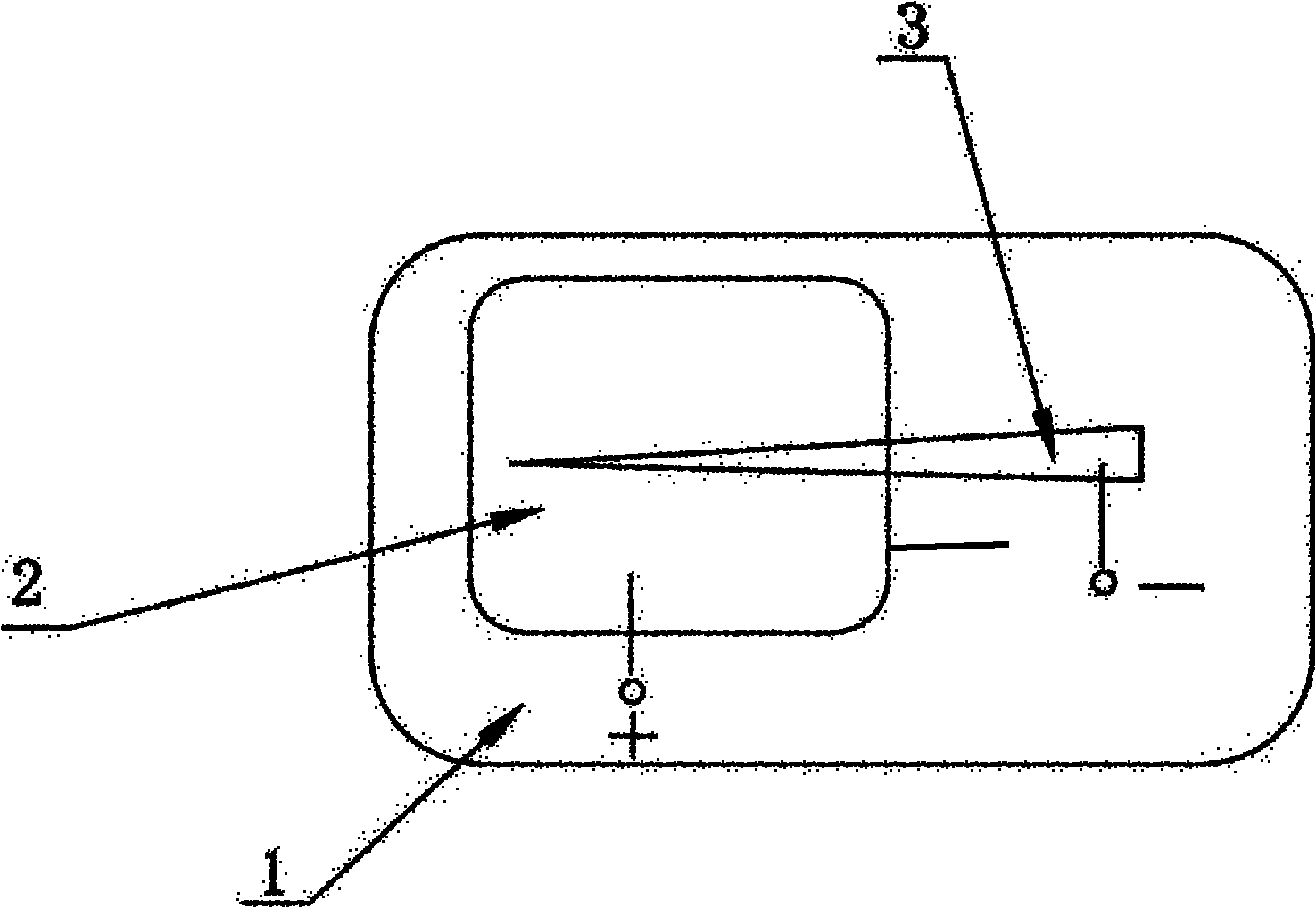

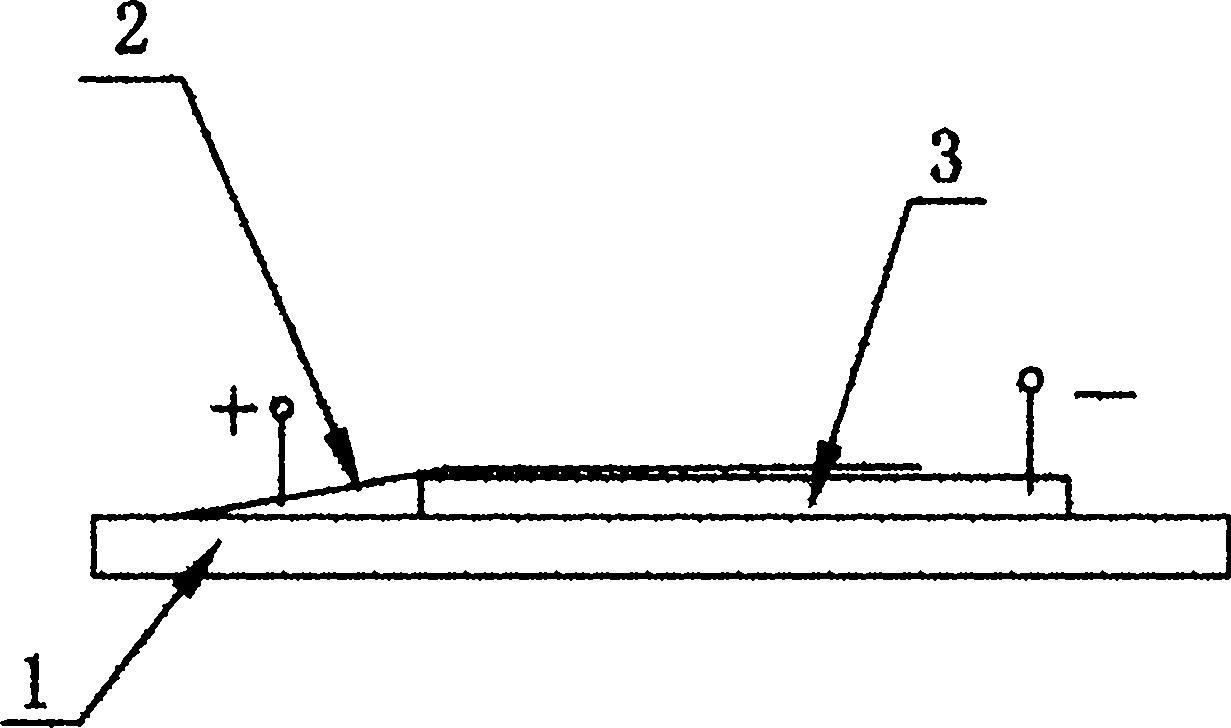

[0048] Get above-mentioned glass slide as transparent insulating smooth substrate, on the substrate, drop a drop of ethanol suspension that contains a cadmium selenide nanoribbon (length is 1.4mm, thickness is about 50nm), after ethanol volatilizes, with The base of the cadmium se...

Embodiment 2

[0051] The poured PDMS (thickness is about 1mm) is standby; the cadmium selenide nanobelt prepared by chemical vapor deposition method is dissolved in ethanol to form the ethanol suspension of cadmium selenide nanobelt for standby; the cadmium selenide nanobelt prepared by chemical vapor deposition is standby; Graphene films using HCl and FeCl 3 .6H 2 O (molar ratio 1:1) mixed solution, after dissolving the copper foil, the graphene film floats on the surface of the solution, and is repeatedly transferred to clean deionized water to remove excess ions, and finally the clean graphene film Float on the surface of deionized water and set aside.

[0052] Take a piece of PDMS as a transparent insulating flexible substrate, drop a drop of ethanol suspension containing a cadmium selenide nanoribbon (1mm in length, about 150nm in thickness) on the substrate, after the ethanol volatilizes, use a cadmium selenide nanoribbon For the base of the nanobelt, pick up the graphene film on th...

Embodiment 3

[0055] Ordinary glass slides are ultrasonically cleaned with deionized water and absolute ethanol, and dried for later use; cadmium selenide nanobelts prepared by chemical vapor deposition are dissolved in ethanol to form ethanol suspensions of cadmium selenide nanobelts for later use ; Graphene films on copper foil prepared by chemical vapor deposition using HCl and FeCl 3 .6H 2 O (molar ratio 1:1) mixed solution, after dissolving the copper foil, the graphene film floats on the surface of the solution, and is repeatedly transferred to clean deionized water to remove excess ions, and finally the clean graphene film Float on the surface of deionized water and set aside.

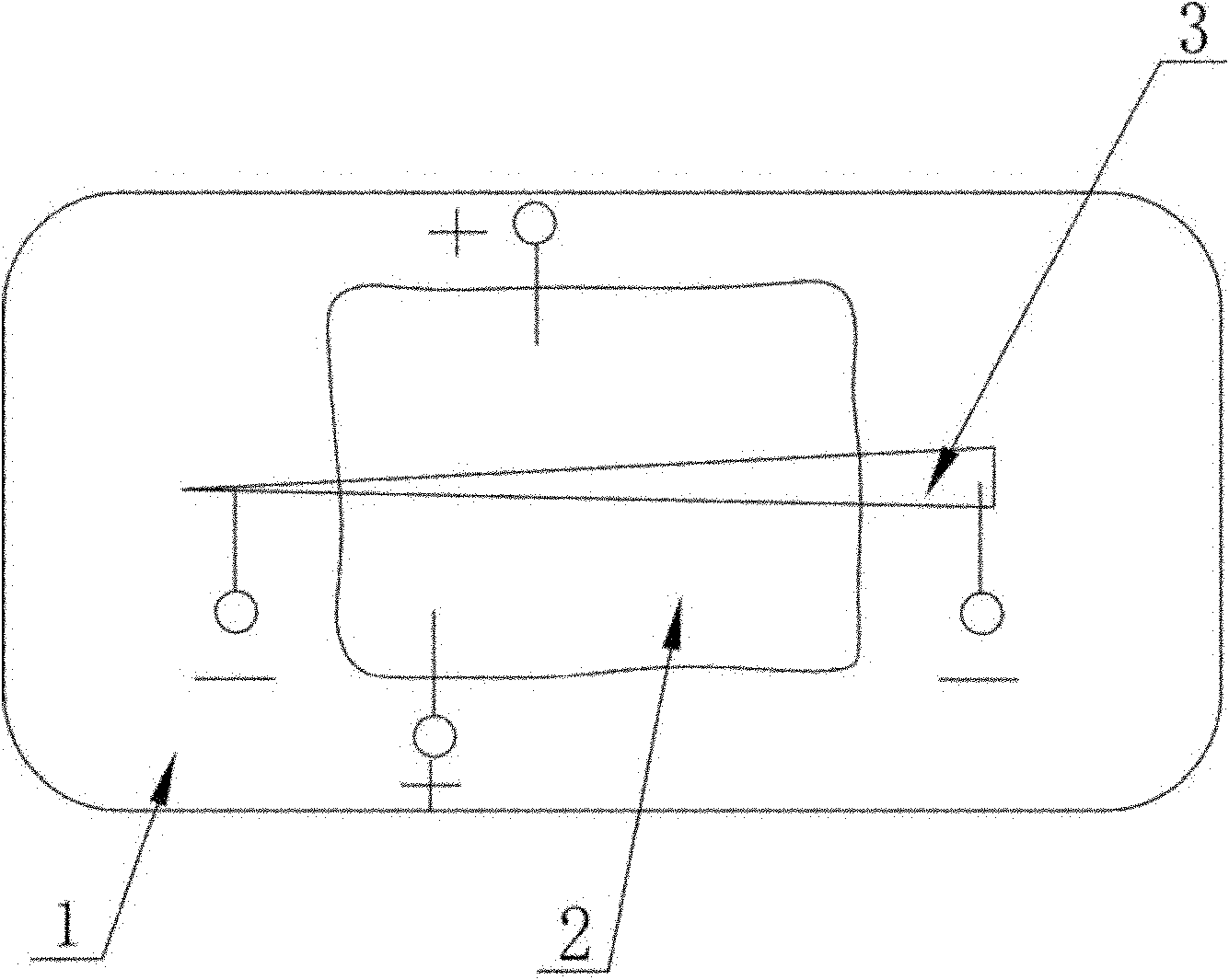

[0056] Take the above-mentioned glass slide as a transparent insulating smooth substrate, drop a drop of ethanol suspension containing a cadmium selenide nanoribbon (1.5mm long, about 200nm thick) on the substrate, after the ethanol volatilizes, use The substrate of the cadmium selenide nanobelt is picked u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com