Sea cucumber feed produced from alfalfa and its manufacturing method

A technology of alfalfa and sea cucumber, applied in animal feed, animal feed, application, etc., can solve the problems of poor breeding effect, easy deterioration of water quality, and low survival rate, so as to improve stress resistance, reduce water pollution, and promote sea cucumber The effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

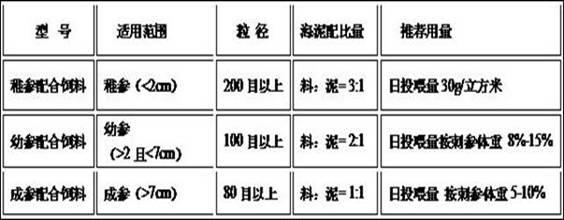

[0033] Special compound feed for juvenile ginseng

[0034] The special compound feed for juvenile ginseng produced from alfalfa contains the following components, according to the weight percentage of each component: 25% alfalfa, 14% soybean meal, 8% peanut meal, 10% corn flour, 1% gluten, seaweed 12% powder, 5% fish meal, 15% scallop powder, 5% shrimp powder, 2% yeast, 2% commercially available multivitamins for aquatic products, and 1% commercially available special minerals for aquatic products.

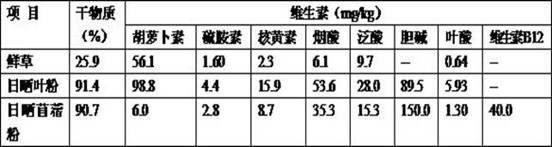

[0035] The alfalfa used is alfalfa hay powder, and its preparation process: the fresh alfalfa grass before the flowering period is harvested and broken into small pieces with a length of 2cm to 3cm, and immediately sent to the dryer by a conveyor, dried at a high temperature of 800°C to 1000°C, and then dried at a high temperature of 800°C to 1000°C. The water content of fresh grass is reduced to 8-15% in a few seconds, and the most suitable range is 10-12%. The dried high-quality...

Embodiment 2

[0047] Special compound feed for young ginseng

[0048]The difference between this example and Example 1 is that the percentages by weight of the components in the raw materials are: 28% alfalfa meal, 16% soybean meal, 8% peanut meal, 10% corn flour, 4% gluten, seaweed 8% powder, 3% fish meal, 10% scallop powder, 8% shrimp powder, 2% yeast, 1.5% commercially available multivitamins for aquatic products, and 1.5% commercially available special minerals for aquatic products;

[0049] Its manufacturing method is different from embodiment 1 in that:

[0050] 3) Superfinely pulverize the coarsely pulverized material to more than 120 mesh;

[0051] 4) Use a 120-mesh sieve to sieve the ultra-finely pulverized material, and the material under the sieve is the finished product, which enters the packaging process.

Embodiment 3

[0053] The difference between this example and Example 2 is that the percentages by weight of the components in the raw materials are: 30% alfalfa meal, 11% soybean meal, 14% peanut meal, 5% corn flour, 5% gluten powder, seaweed 3% powder, 5% fish meal, 12% scallop powder, 4% shrimp powder, 6% yeast, 3% commercially available multivitamins for aquatic products, and 2% commercially available special minerals for aquatic products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com