A kind of hawthorn fruit juice drink and preparation method thereof

A technology of hawthorn pulp and hawthorn pulp, applied in food preparation, application, food science, etc., to achieve the effects of rich nutrition, high pulp content, and increased dietary fiber content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

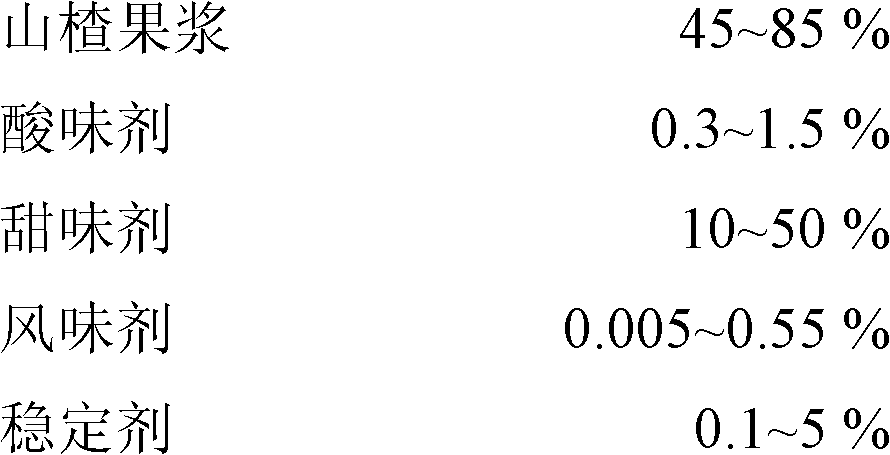

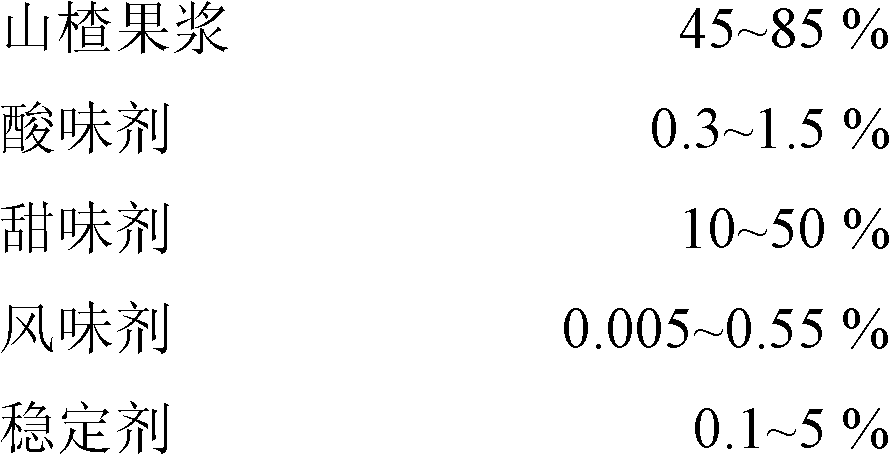

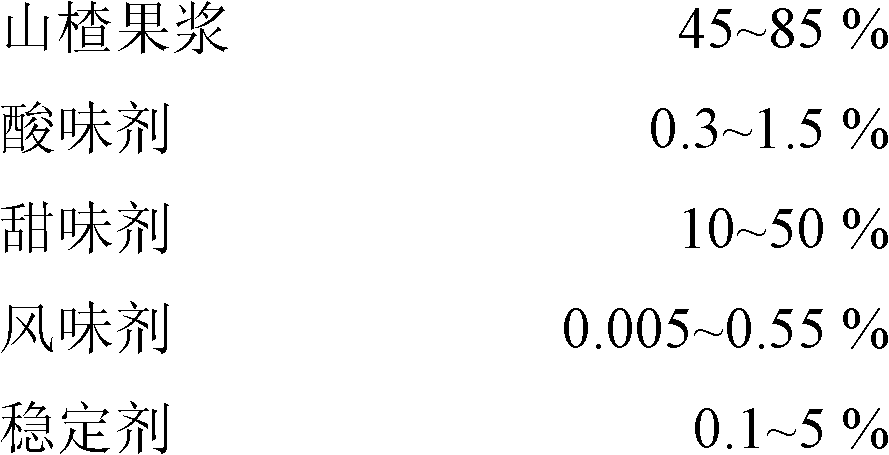

Method used

Image

Examples

Embodiment 1

[0030] Take 1000 kg of hawthorn; sort the raw hawthorn and rinse it with water; add 2000 kg of drinking water to boil the hawthorn fruit, separate the core, and beat the pulp to make 2500 kg of hawthorn pulp; 16 kg of citric acid; 560 kg of sucrose; Base maltol 0.28 kg; pectin 3.0 kg; agar 3.0 kg melted and pumped into the blending tank, add 2100 kg of drinking water and mix thoroughly; then through colloid grinding, the hawthorn pulp particle size is less than 0.1 mm; homogeneous pressure is 20MP; Degassing; instant sterilization at 121°C; hot filling at 80°C; capping; cooling to 20°C; packaging is the finished product of hawthorn pulp juice drink.

Embodiment 2

[0032] Take 10,000 kg of hawthorn; sort the raw hawthorn and rinse it with water; add 50,000 kg of drinking water to boil the hawthorn fruit, separate the core, and beat the pulp to make 50,000 kg of hawthorn pulp; 810 kg of malic acid; 16,200 kg of fructose syrup 400 kilograms of maltol; 400 kilograms of xanthan gum; 400 kilograms of carrageenan melted and then pumped into the blending tank, added 40000kg of drinking water and fully mixed; then through colloid grinding, the hawthorn pulp particle size is less than 0.1 mm; the homogeneous pressure is 50MP; degassing; instant sterilization at 121°C; hot filling at 90°C;

Embodiment 3

[0034] Take 100 kg of hawthorn; sort the raw hawthorn and rinse it with water; add 300 kg of drinking water to boil the hawthorn fruit, separate the core, and beat the pulp to make 340 kg of hawthorn pulp; 2.4 kg of tartaric acid; 72 kg of sucrose; 0.24 kg of maltol; 4.8 kg of gelatin; 4.8 kg of sodium hydroxymethyl cellulose melted and pumped into the blending tank, adding 450 kg of drinking water and mixing thoroughly; then through colloid grinding, the particle size of hawthorn pulp is less than 0.1 mm; homogenization pressure 35MP; degassing; instant sterilization at 121°C; hot filling at 85°C;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com