A kind of patchouli oil microcapsules and its preparation method and application

A technology of patchouli oil and microcapsules, which is applied in microcapsules, capsule delivery, pharmaceutical formulations, etc., can solve the problems of low drug efficacy, prolonged efficacy, poor stability, etc., to eliminate strong odor, prolong efficacy, Antibacterial enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

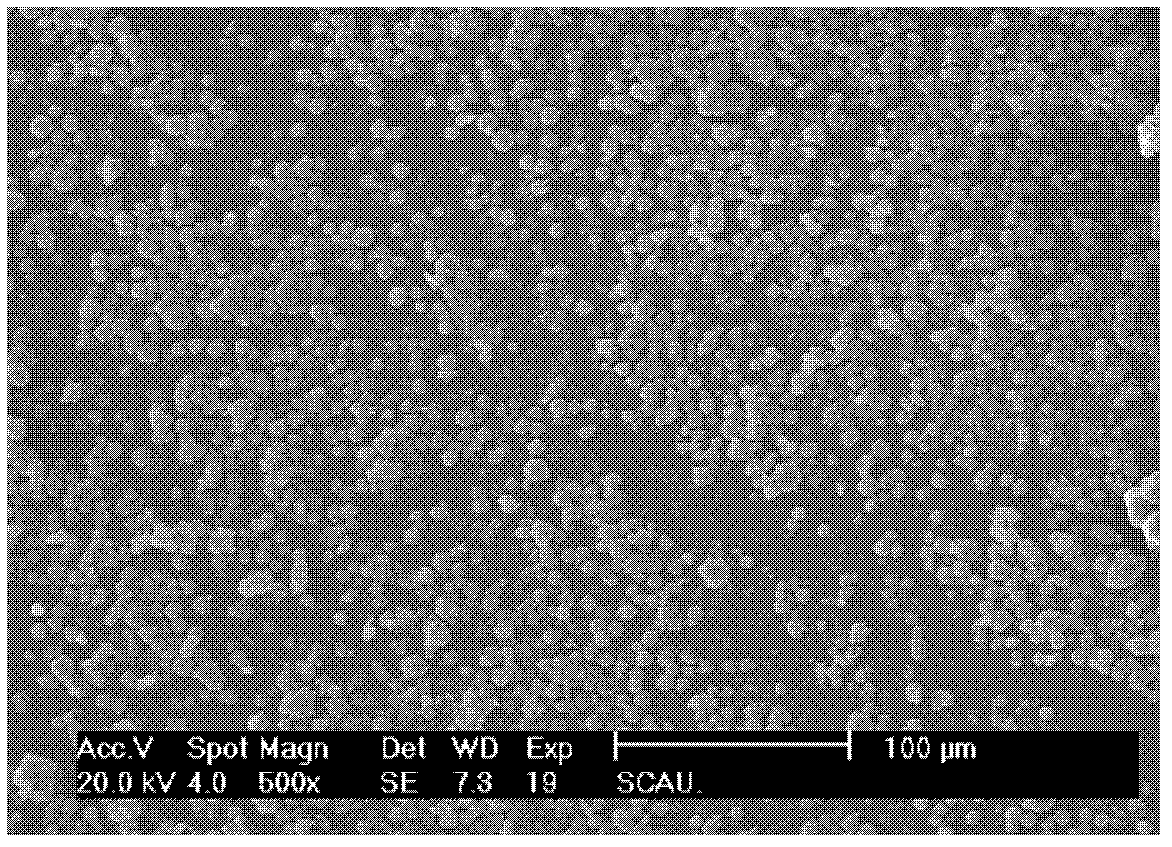

[0051] A preparation method of patchouli oil microcapsules, comprising the following steps:

[0052] 1) Dissolve 1g of chitosan in 60mL of 1% (mass fraction) acetic acid solution, adjust the pH to 8, let stand overnight, filter with suction, put the filter cake in a constant temperature water bath at 75°C, add 30mL of 4g 2,3- After reacting the isopropanol solution of epoxypropyltrimethylammonium chloride for 8 hours, precipitate with absolute ethanol, wash, filter with suction, and dry to obtain chitosan quaternary ammonium salt, which is set aside.

[0053] 2) 0.5g chitosan, 0.5g chitosan quaternary ammonium salt are dissolved in 100mL 1% (mass fraction) acetic acid solution, are mixed with chitosan, chitosan quaternary ammonium salt compound solution that total concentration is 1% spare.

[0054] 3) Dissolve 1.5g of gum arabic in 100mL of 40°C distilled water to prepare a gum arabic solution with a concentration of 1.5%; add 0.6g of Span-80 and 1.25g of patchouli oil to th...

Embodiment 2

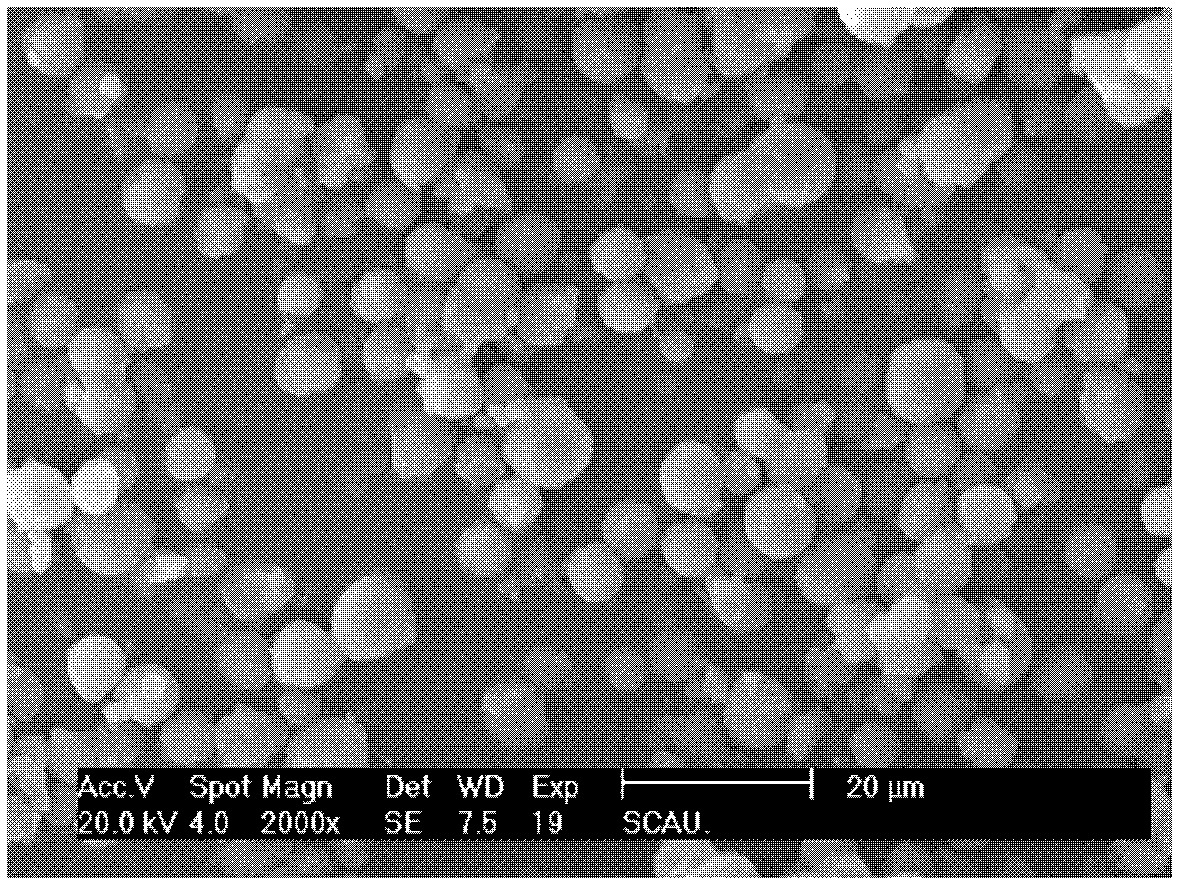

[0063] A preparation method of patchouli oil microcapsules, comprising the following steps:

[0064] 1) Dissolve 1g of chitosan in 60mL of 1% (mass fraction) acetic acid solution, adjust the pH to 8, let stand overnight, filter with suction, put the filter cake in a constant temperature water bath at 75°C, add 30mL of 4g 2,3- After reacting the isopropanol solution of epoxypropyltrimethylammonium chloride for 8 hours, precipitate with absolute ethanol, wash, filter with suction, and dry to obtain chitosan quaternary ammonium salt, which is set aside.

[0065] 2) Dissolve 0.4g chitosan and 0.6g chitosan quaternary ammonium salt in 100mL1% (mass fraction) acetic acid solution, and prepare chitosan and chitosan quaternary ammonium salt complex solution with a total concentration of 1%. .

[0066] 3) Dissolve 1g of gum arabic in 100mL of 40°C distilled water to prepare a gum arabic solution with a concentration of 1%; add 1g of Tween-80 to the gum arabic solution and mix well, th...

Embodiment 3

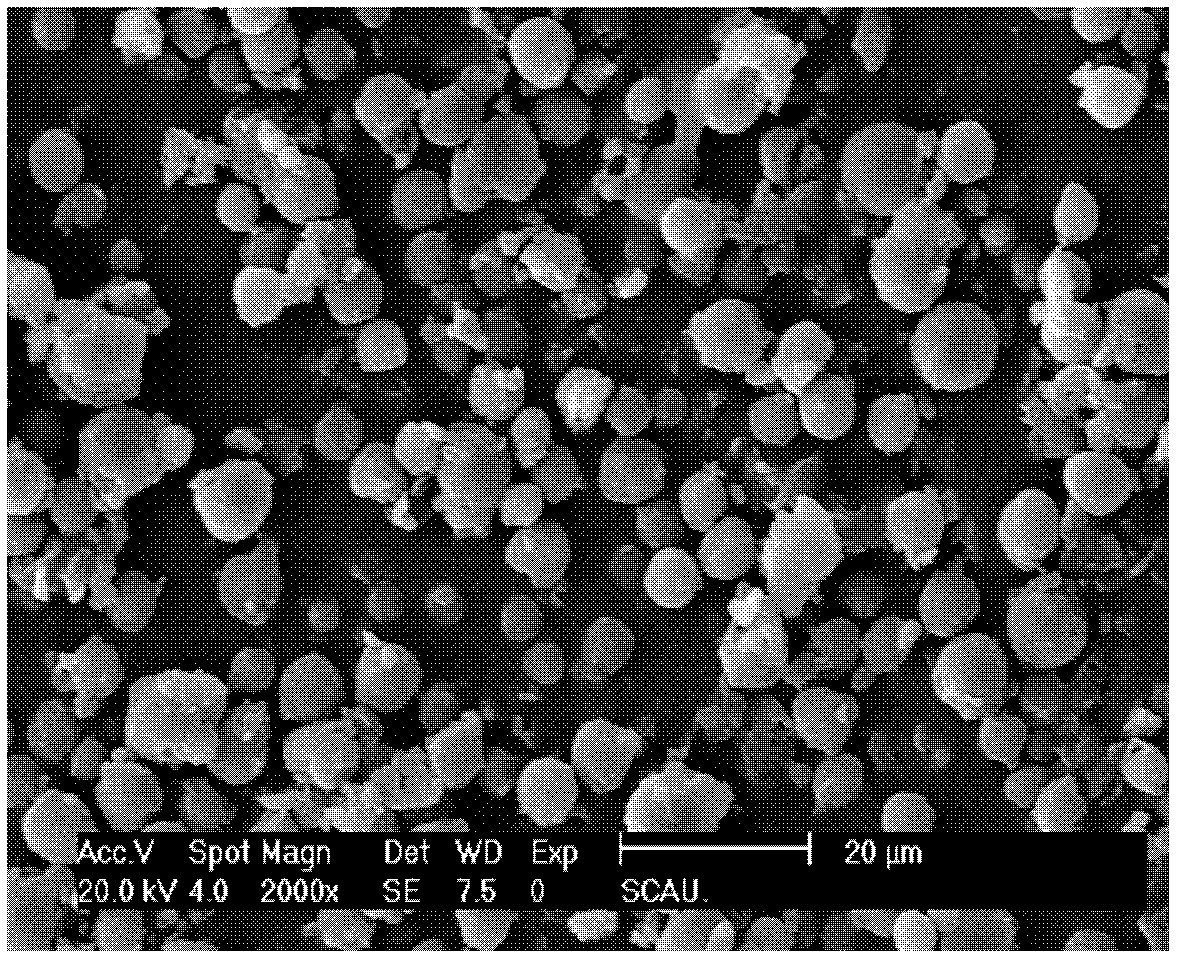

[0075] A preparation method of patchouli oil microcapsules, comprising the following steps:

[0076] 1) Dissolve 1g of chitosan in 60mL of 1% (mass fraction) acetic acid solution, adjust the pH to 8, let stand overnight, filter with suction, put the filter cake in a constant temperature water bath at 75°C, add 30mL of 4g 2,3- After reacting the isopropanol solution of epoxypropyltrimethylammonium chloride for 8 hours, precipitate with absolute ethanol, wash, filter with suction, and dry to obtain chitosan quaternary ammonium salt, which is set aside.

[0077] 2) Dissolve 0.4g chitosan and 0.6g chitosan quaternary ammonium salt in 100mL1% (mass fraction) acetic acid solution, and prepare chitosan and chitosan quaternary ammonium salt complex solution with a total concentration of 1%. .

[0078] 3) Dissolve 2g of gum arabic in 100mL of 30°C distilled water to prepare a gum arabic solution with a concentration of 2%; add 0.4g of Span-80 and 0.4g of polyethylene glycol-600 to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com