Method for preparing nanometer ceria by solid state reaction at room temperature

A nano-ceria, solid-phase reaction technology at room temperature, applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problems of harsh preparation conditions, large amount of organic solvent, complicated process, etc., and achieves low reaction temperature. , environment-friendly, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the method for preparing nano-cerium dioxide by solid phase reaction at room temperature is carried out according to the following steps:

[0018] 1. Press CeCl 3 ·7H 2 The molar ratio of O and alkali metal hydroxide is 1:3, respectively weigh CeCl 3 ·7H 2 O and alkali metal hydroxide, then CeCl 3 ·7H 2 O and alkali metal hydroxide are ground into powder respectively at room temperature and then mixed to obtain a mixture;

[0019] 2. Grinding the mixture obtained in step 1 for 15 to 30 minutes to obtain a mixture;

[0020] 3. The mixture obtained in step 2 is ultrasonically cleaned for more than 3 times with deionized water, and then placed in a constant temperature drying oven after suction filtration, and dried at 80-200° C. for 1-2 hours to obtain nano-cerium dioxide.

[0021] In this embodiment, a mortar or a ball mill is used for grinding, and the mortar or ball mill used must be resistant to strong alkali corrosion.

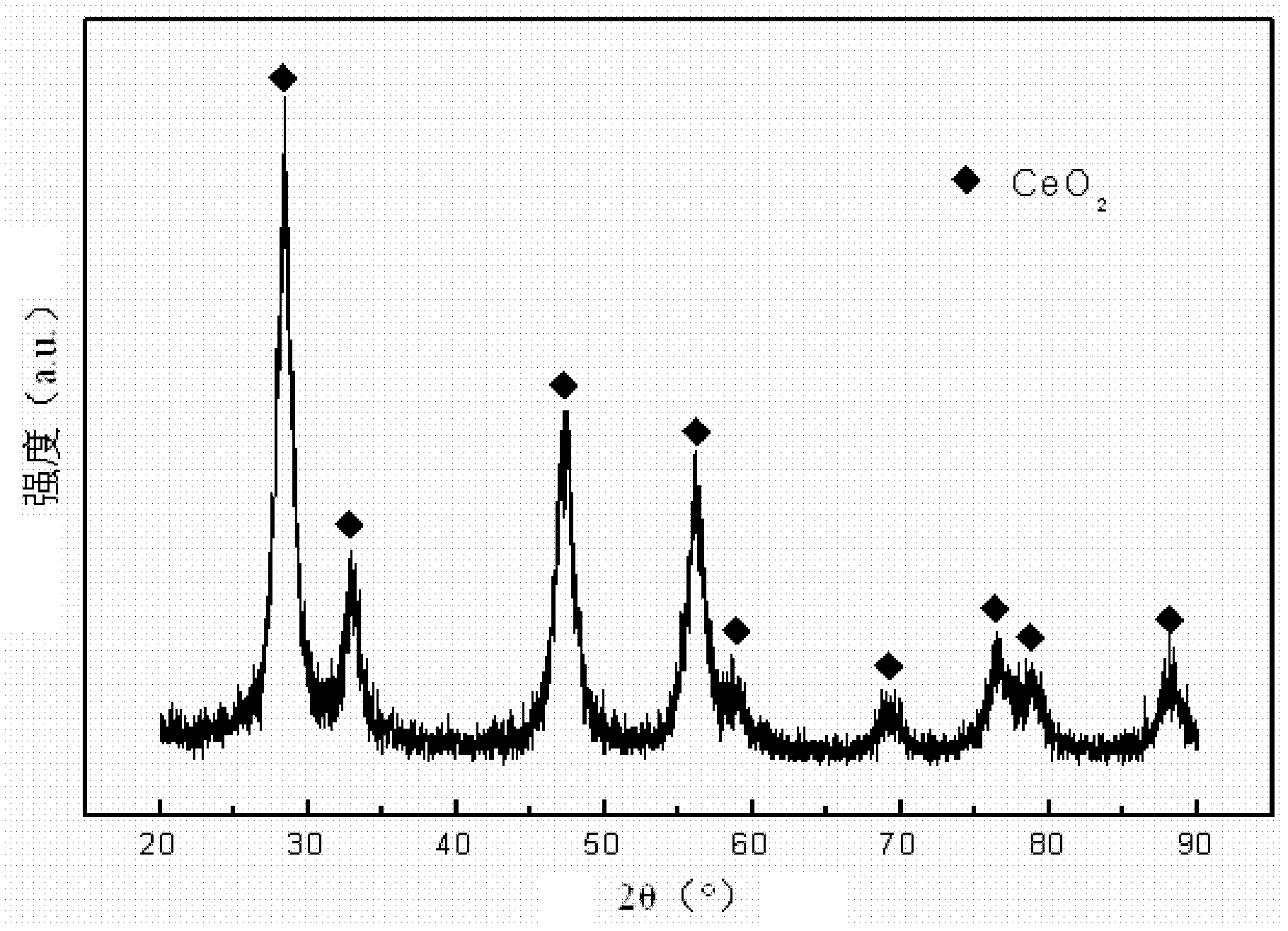

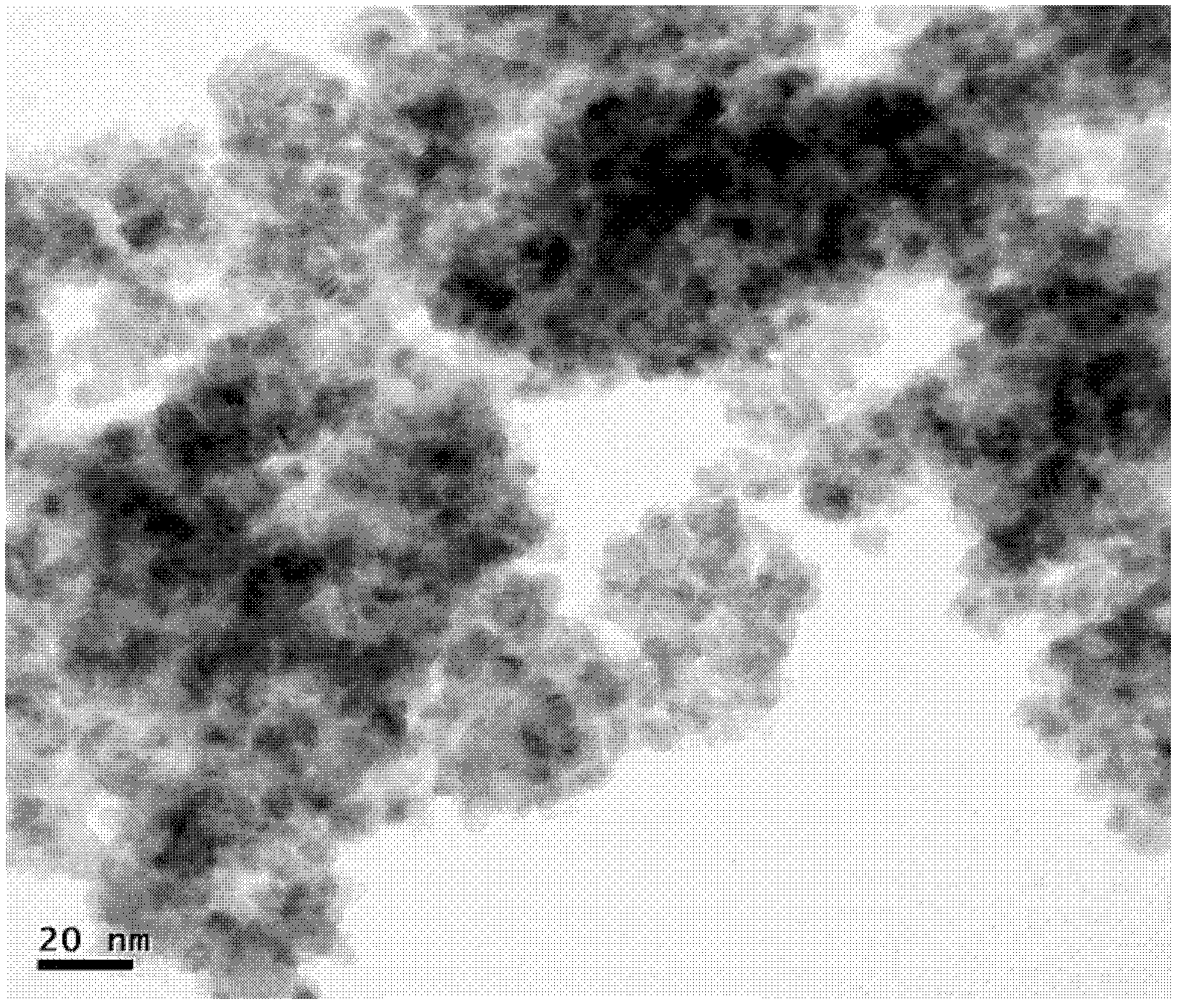

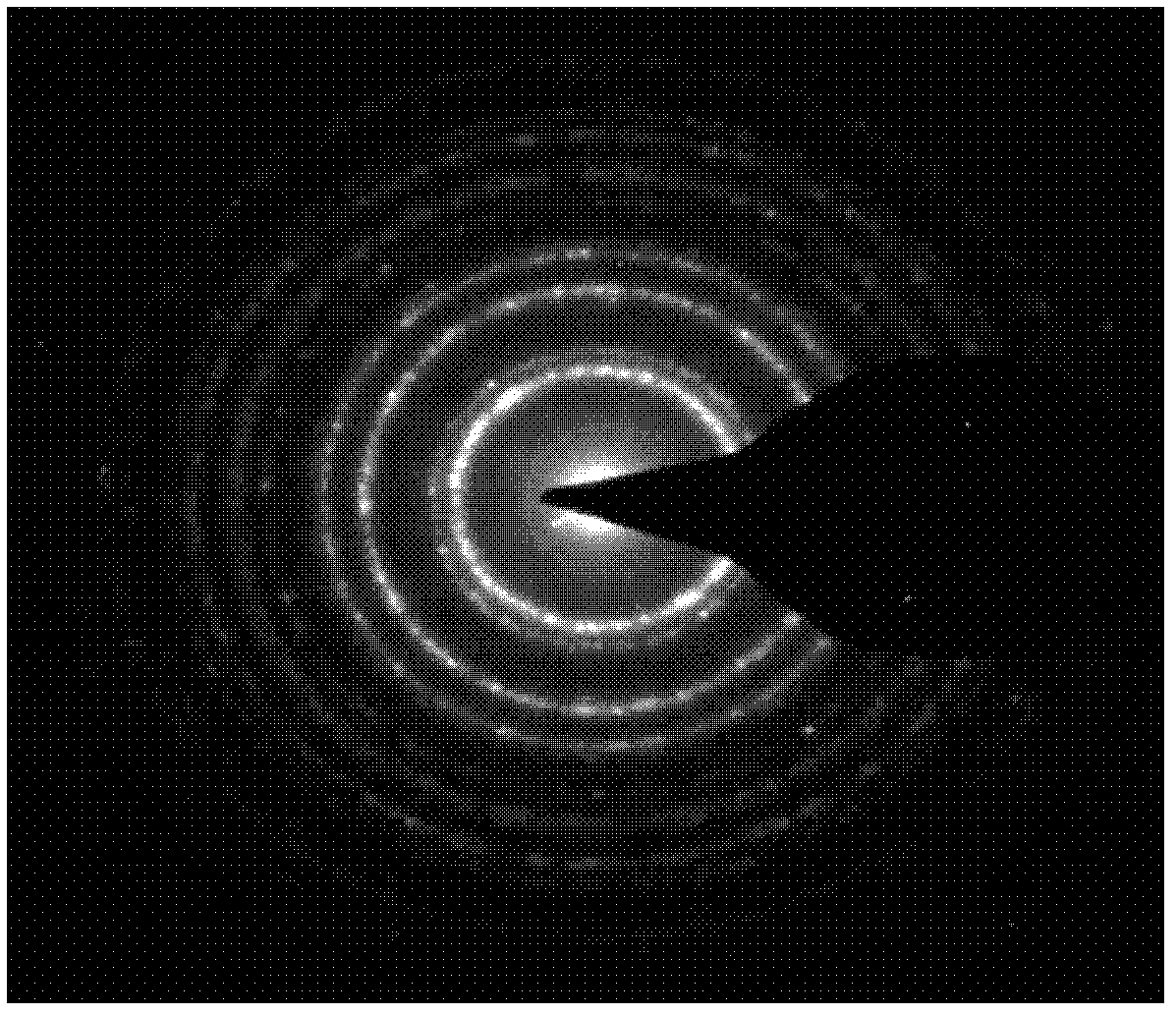

[0022] The nan...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment is different from Embodiment 1 in that: the alkali metal hydroxide in Step 1 is sodium hydroxide or potassium hydroxide. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the drying temperature in Step 3 is 100-180°C. Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com