Preparation method of high-performance polyacrylonitrile-based carbon fiber precursor

A polyacrylonitrile-based carbon fiber and polyacrylonitrile spinning technology, which is applied in the direction of drawing spinning, artificial filament heat treatment, etc., can solve the problems such as the related reports on the preparation method of polyacrylonitrile-based carbon fiber precursor, etc. The effect of increasing the degree of orientation, increasing the spinning speed, and increasing the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

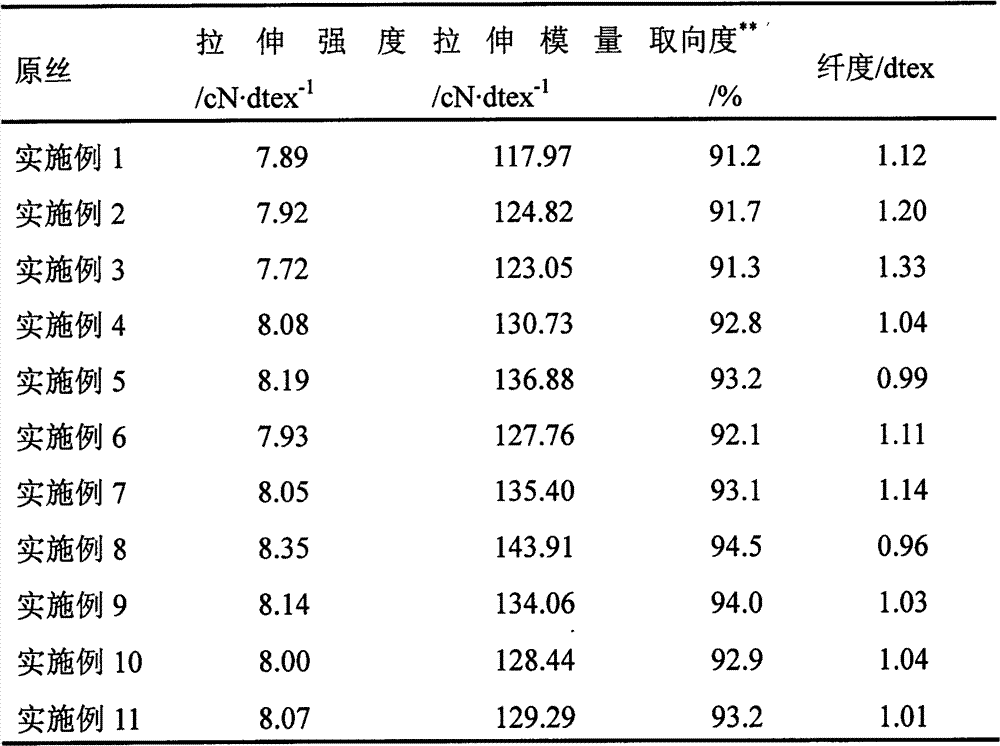

Examples

Embodiment 1

[0032] A polyacrylonitrile resin with a weight-average molecular weight of 2,730,000 and a molecular weight distribution of 2.81 was added into dimethylformamide, and stirred at 50°C for 2 hours to obtain a dilute ultra-high molecular weight polyacrylonitrile solution with a mass concentration of 0.5%. A polyacrylonitrile resin with a weight average molecular weight of 105,000 and a molecular weight distribution of 2.33 was dissolved in the dilute polyacrylonitrile solution, stirred at 55°C for 2 hours, and then stirred at 80°C for 5 hours to obtain a spinning dope. The spinning stock solution is extruded through the spinneret, and after passing through a 2cm air section, it enters a dimethylformamide / water coagulation bath with a temperature of 25°C and a mass concentration of dimethylformamide of 40% for coagulation and formation. The ratio of the winding speed of a winding roller to the stock solution extrusion speed is 18. The as-spun filaments were washed and stretched 1....

Embodiment 2

[0034] A polyacrylonitrile resin with a weight average molecular weight of 21100000 and a molecular weight distribution of 2.55 was added into dimethylformamide, and stirred at 55°C for 2 hours to obtain a dilute ultrahigh molecular weight polyacrylonitrile solution with a mass concentration of 1%. A polyacrylonitrile resin with a weight average molecular weight of 85,000 and a molecular weight distribution of 2.50 was dissolved in the dilute polyacrylonitrile solution, stirred at 60°C for 2 hours, and then stirred at 80°C for 5 hours to obtain a spinning dope. The spinning stock solution is extruded through the spinneret, and after passing through a 2cm air section, it enters a dimethylformamide / water coagulation bath with a temperature of 25°C and a mass concentration of dimethylformamide of 40% for coagulation and formation. The ratio of the winding speed of a winding roller to the extrusion speed of the stock solution is 15. The as-spun filaments were washed and stretched ...

Embodiment 3

[0036]A polyacrylonitrile resin with a weight average molecular weight of 1,690,000 and a molecular weight distribution of 3.06 was added to dimethyl sulfoxide, and stirred at 50° C. for 2 hours to obtain a dilute solution of ultrahigh molecular weight polyacrylonitrile with a mass concentration of 1%. A polyacrylonitrile resin with a weight average molecular weight of 143,000 and a molecular weight distribution of 2.61 was dissolved in the dilute polyacrylonitrile solution, stirred at 55°C for 3 hours, and then stirred at 75°C for 5 hours to obtain a spinning dope. The spinning stock solution is extruded through the spinneret, and after passing through a 2cm air section, it enters a dimethyl sulfoxide / water coagulation bath with a temperature of 25°C and a mass concentration of dimethyl sulfoxide of 50% for coagulation and formation. The ratio of the winding speed of a winding roller to the extrusion speed of the stock solution is 12. The as-spun filaments were washed and str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com