Resistive humidity sensor capable of measuring humidity in low-humidity environment and manufacturing method thereof

A technology of environmental humidity and humidity sensitive components, applied in the direction of material resistance, etc., can solve the problems of insufficient humidity detection, difficulty in measurement, low conductivity, etc., and achieve the effects of avoiding processing difficulties, simple preparation process, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

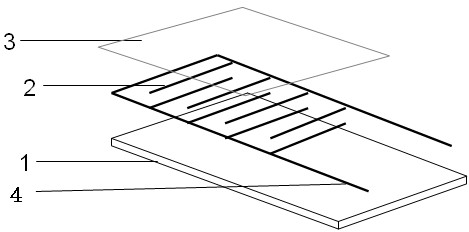

[0024] 1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0025] 2) The three-necked flask was subjected to water and oxygen removal treatment, and 10 grams of 3-aminopropyltriethoxysilane, 10 grams of bromo-n-butane and 2 milliliters of absolute ethanol were sequentially added. Nitrogen was passed for 10 minutes with stirring at room temperature, and then the temperature was raised to 30° C., and reacted for 10 hours under the protection of nitrogen. The temperature of the obtained reactant was further raised to 40° C., and 2 ml of aqueous hydrochloric acid solution with a pH value of 1 was added dropwise, and the reaction was continued for 0.5 hours. Afterwards, the reaction solution was diluted with 5 ml of absolute ethanol, precipitated in ether, then filtered, and dried in vacuo for 12 hours to obtain a light yellow solid product (trihydroxysilylpropyl) n-butylammonium bromide (APSB) ...

Embodiment 2

[0029] 1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0030] 2) The three-necked flask was subjected to water and oxygen removal treatment, and 12 grams of 3-aminopropyltriethoxysilane, 12 grams of bromo-n-butane and 5 milliliters of absolute ethanol were added in sequence. Nitrogen was passed for 20 minutes under normal temperature stirring, and then the temperature was raised to 40° C., and reacted for 12 hours under the protection of nitrogen. The obtained reactant was heated up to 45° C., and 3 ml of aqueous hydrochloric acid with a pH value of 1.5 was added dropwise, and the reaction was continued for 1 hour. Afterwards, the reaction solution was diluted with 8 milliliters of absolute ethanol, precipitated in ether, then filtered, and vacuum-dried for 15 hours to obtain the pale yellow solid product APSB;

[0031] 3) Disperse 4 mg of graphene oxide in 2 ml of water by ultrasonic t...

Embodiment 3

[0034] 1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0035] 2) The three-necked flask was subjected to water and oxygen removal treatment, and 15 grams of 3-aminopropyltriethoxysilane, 14 grams of bromo-n-butane and 3 milliliters of absolute ethanol were added in sequence. Nitrogen was passed for 25 minutes under normal temperature stirring, then the temperature was raised to 50°C, and the reaction was carried out under nitrogen protection for 20 hours. The obtained reactant was further heated to 55° C., and 3.5 ml of aqueous hydrochloric acid with a pH value of 3 was added dropwise, and the reaction was continued for 1.5 hours. Afterwards, the reaction solution was diluted with 15 milliliters of absolute ethanol, precipitated in ether, then filtered, and vacuum-dried for 20 hours to obtain the pale yellow solid product APSB;

[0036]3) Disperse 6 mg of graphene oxide in 3 ml of water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com