Dye-sensitized solar cell double-layer composite film electrode with high photoelectric conversion efficiency and preparation method

A photoelectric conversion efficiency, solar cell technology, applied in photosensitive devices, capacitor electrodes, photovoltaic power generation, etc., can solve the problems of reducing open circuit voltage, affecting the rapid progress of batteries, reducing short-circuit photocurrent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

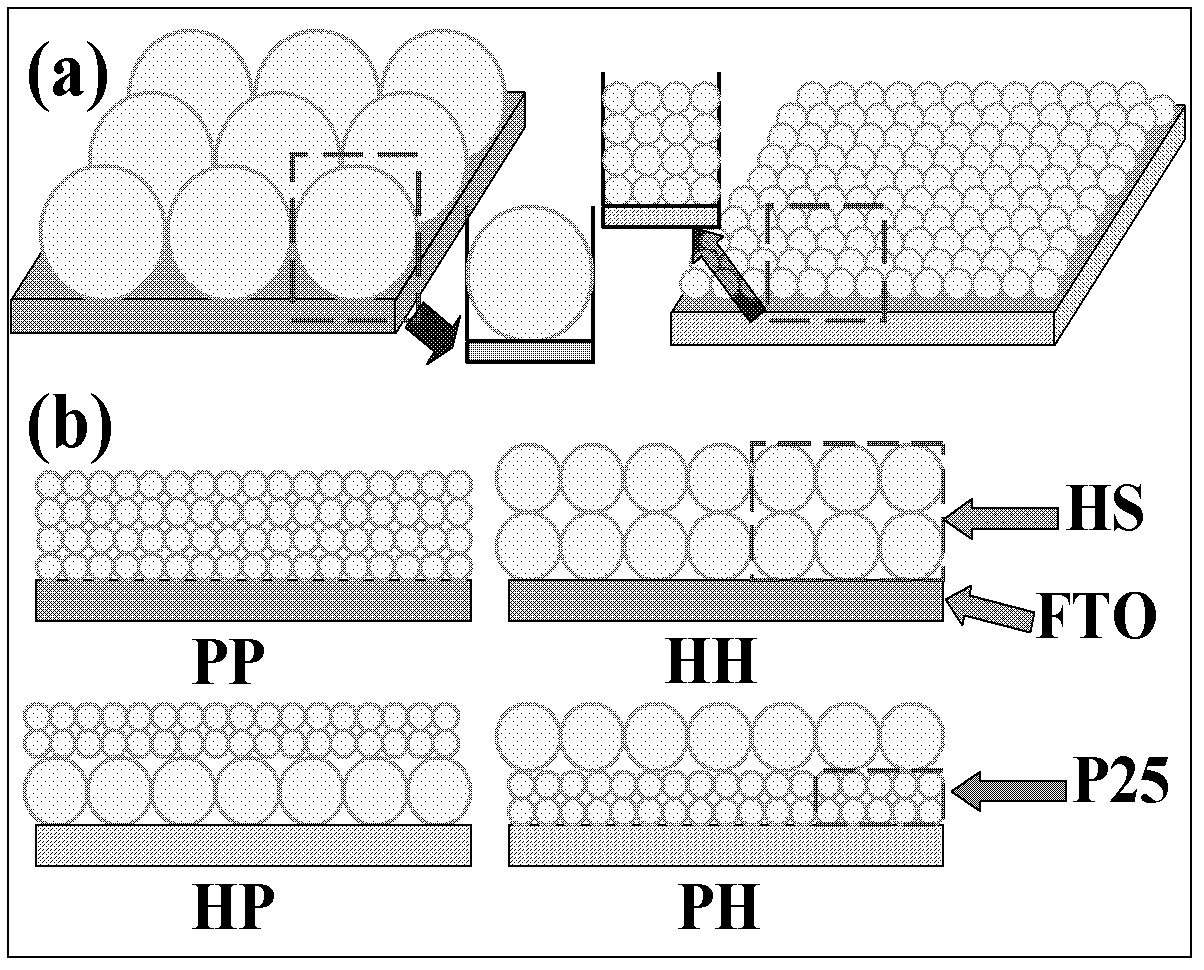

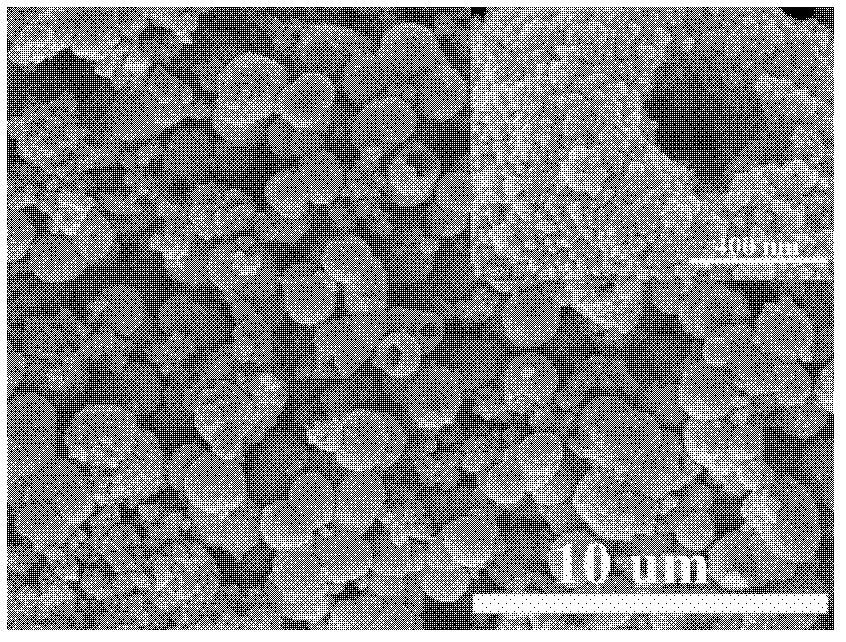

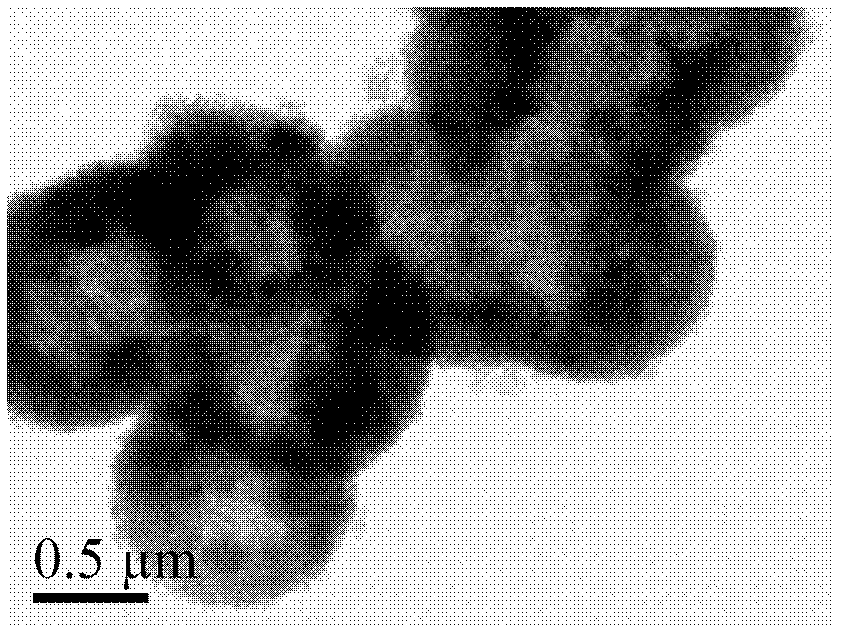

[0032] In order to prepare double-layer composite film electrodes for dye-sensitized solar cells with high photoelectric conversion efficiency, P25 nanoparticle slurry and TiO 2 Hollow sphere slurry, and then apply the P25 nanoparticle slurry on the fluorine-doped tin oxide transparent conductive glass substrate by using the doctor blade method, and form a dense P25 nanoparticle film layer after drying and calcining. Then use the scraper method to remove the TiO 2 The hollow sphere slurry is coated on the dense P25 nanoparticle film layer, and then dried and calcined to form a double-layer composite film electrode. The detailed experimental process is as follows: 10 milliliters of ethanol, 1 milliliter of acetylacetone and 1 milliliter of Triton X-100 were successively added into two 100 milliliter mortars, and mixed evenly. Then add 2 grams of P25 nanoparticle powder and TiO 2 Hollow spherical powder. It was milled for 30 min to form P25 nanoparticle slurry and TiO 2 Holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com