A high-power high-brightness light-emitting diode chip and its manufacturing method

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problem of weak coupling between photonic crystals and low-level waveguides, and does not fundamentally solve the problems of LED heat dissipation and current congestion, so as to reduce current congestion phenomenon, improvement of light extraction efficiency, and improvement of heat dissipation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

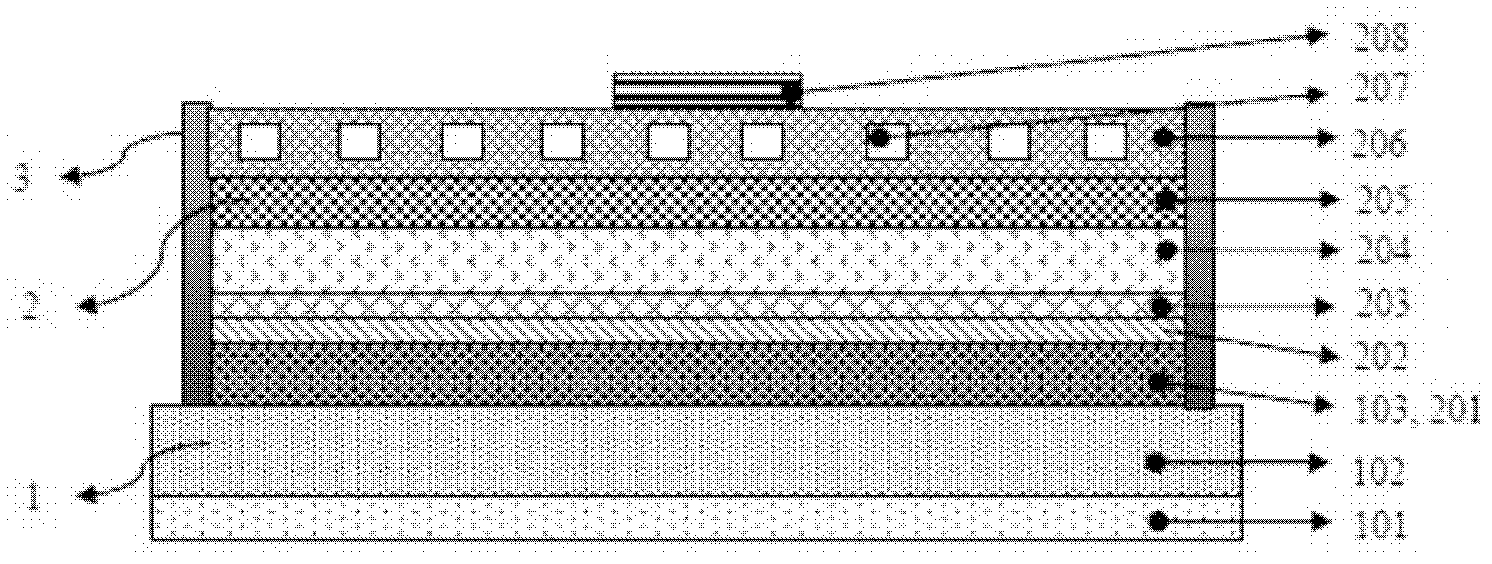

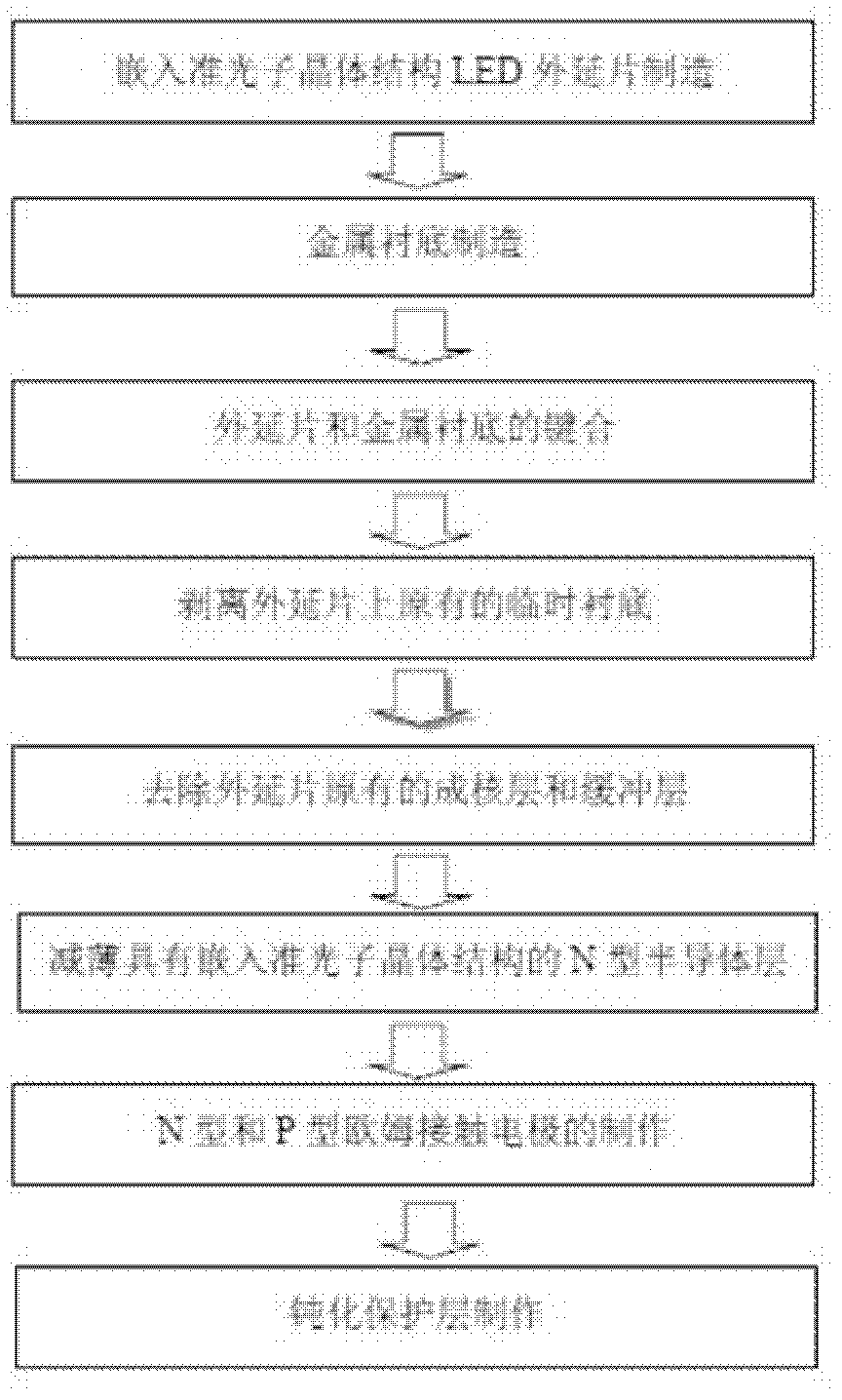

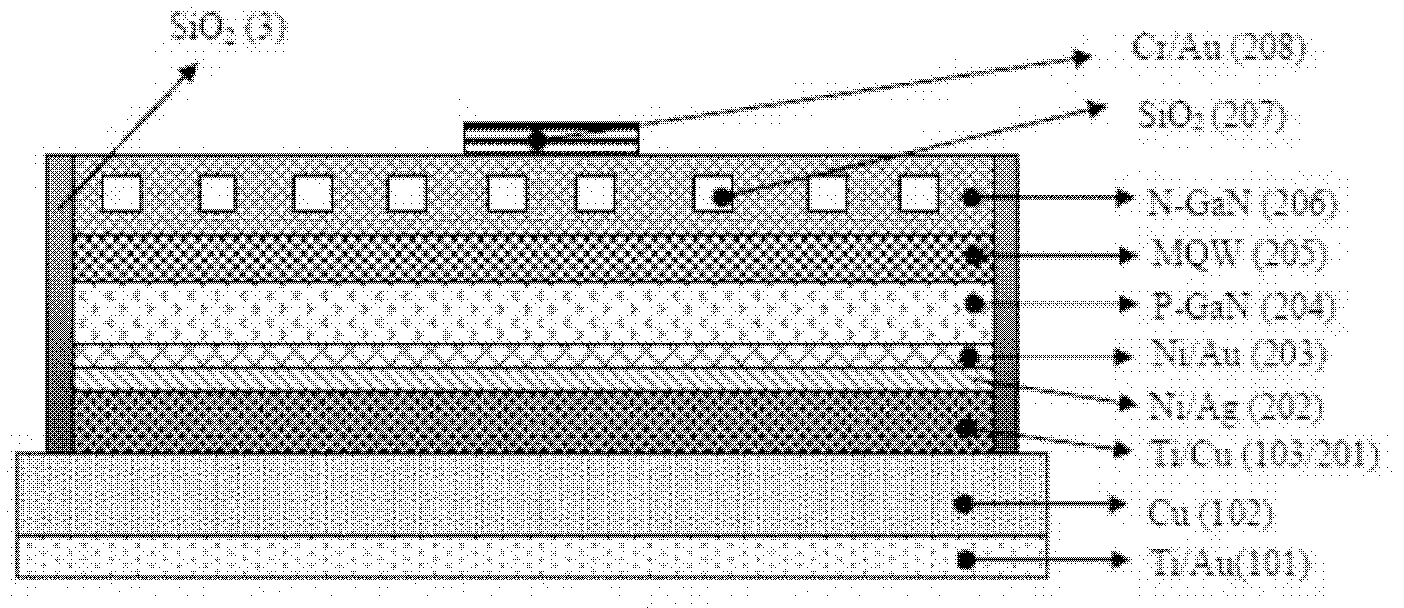

[0102] With metal copper (Cu) as the metal substrate 1, the vertical structure GaN-based embedded quasi-photonic crystal LED is the embodiment 1, and its specific structural diagram is as follows image 3 shown. Metal substrate 1 vertical structure GaN-based embedded quasi-photonic crystal LED includes from bottom to top: Ti / Au P-type ohmic contact electrode 101; metal Cu transfer metal substrate 102; Ti / Cu material metal bonding layer I103 and metal Bonding layer II201; metal reflective layer 202 of Ni / Ag; current spreading and P-type ohmic contact layer 203 of Ni / Au; P-type semiconductor layer 204 of P-GaN; 5-layer InGaN / GaN multiple quantum well (MQW) light emitting Layer 205; an embedded quasi-photonic crystal structure N-type semiconductor layer 206 of N-GaN; a quasi-photonic crystal structure SiO embedded in the N-type semiconductor layer 206 2 Nano dielectric pillar 207; N-type ohmic contact electrode 208 of Cr / Au; SiO 2 Passivation protection layer 3.

[0103] The m...

Embodiment 2

[0138] like Figure 7 , Figure 8 As shown, the present embodiment is similar to Embodiment 1, and the difference is that the substrate 102 is a copper alloy; the current spreading layer of ITO and the P-type ohmic contact layer 203; the metal reflective layer 202 of Ag / Cu; silicon nitride (Si 3 N 4 ) passivation protection layer 3. The characteristic structure of the quasi-photonic crystal structure embedded in the N-type semiconductor layer 206 is a 12-fold sunflower-type two-dimensional quasi-photonic crystal structure 514. The average diameter of the air holes is 80nm, and the distance between the centers of the nearest air holes is about 200nm. Height 120nm.

[0139] Figure 9 In order to improve electrical characteristics, improve current congestion. To achieve uniform current distribution and increase the light output area, the N-type ohmic contact electrode 208 on the light output surface can adopt a patterned electrode structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com