Silicoaluminophosphate molecular sieve catalyst, preparation method, and use thereof

A silicoaluminophosphate, catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high environmental protection pressure, environmental pollution, increased cost, etc., and achieve the effect of low cost and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

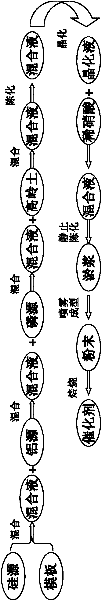

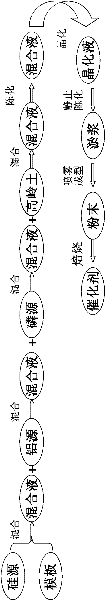

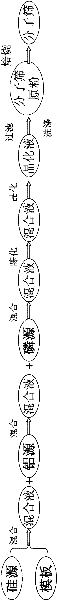

[0076] With the 85% phosphoric acid of 443g, the pseudo-boehmite of 780g, the 40% silica sol of 171g, the triethylamine of 582g, the deionized water of 1784g, 400g kaolin according to figure 1 The process shown is carried out, wherein the aging conditions are: temperature: 25°C, time: 4 hours; the crystallization conditions are: temperature: 200°C, time: 48 hours; add 120g of dilute nitric acid (20%) to the obtained crystallization solution and mix , Mixed solution aging conditions: temperature: 25°C, time: 2 hours; after aging, the slurry is sprayed. Spray drying conditions: inlet temperature: 260°C, outlet temperature: 170°C. The obtained samples were roasted in a retort furnace, the roasting conditions: temperature: 550° C., time: 7 hours.

Embodiment 2

[0078] 400g of 85% phosphoric acid, 800g of pseudoboehmite, 180g of 40% silica sol, 600g of triethylamine, 2000g of deionized water, and 400g of kaolin according to figure 1 The process shown is carried out, wherein the aging conditions are: temperature: 25°C, time: 2 hours; crystallization conditions are: temperature: 200°C, time: 50 hours; add 150g of dilute nitric acid (20%) to the obtained crystallization solution and mix , Mixed solution aging conditions: temperature: 25°C, time: 2 hours; after aging, the slurry is sprayed. Spray drying: inlet temperature: 250°C, outlet temperature: 160°C. The obtained samples were calcined in a kettle furnace, the calcining conditions: temperature: 600° C., time: 6 hours.

Embodiment 3

[0080] 400g of 85% phosphoric acid, 850g of pseudoboehmite, 200g of 40% silica sol, 600g of triethylamine, 2000g of deionized water, and 400g of kaolin according to figure 1 The process shown is carried out, wherein the aging conditions are: temperature: 25°C, time: 2 hours; crystallization conditions are: temperature: 200°C, time: 50 hours; add 100g of dilute nitric acid (20%) to the obtained crystallization solution and mix , Mixed solution aging conditions: temperature: 25°C, time: 2 hours; after aging, the slurry is sprayed. Spray drying: inlet temperature: 250°C, outlet temperature: 160°C. The obtained samples were calcined in a kettle furnace, the calcining conditions: temperature: 600° C., time: 6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com