A method for continuously preparing dichloropropanol with glycerol and hydrochloric acid

A technology of dichloropropanol and hydrochloric acid, applied in the direction of introducing halogen preparation, organic chemistry, etc., can solve the problems of low HCL gas absorption concentration, multiple equipment, inconvenient operation, etc., and achieve the effect of expanding the source range and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

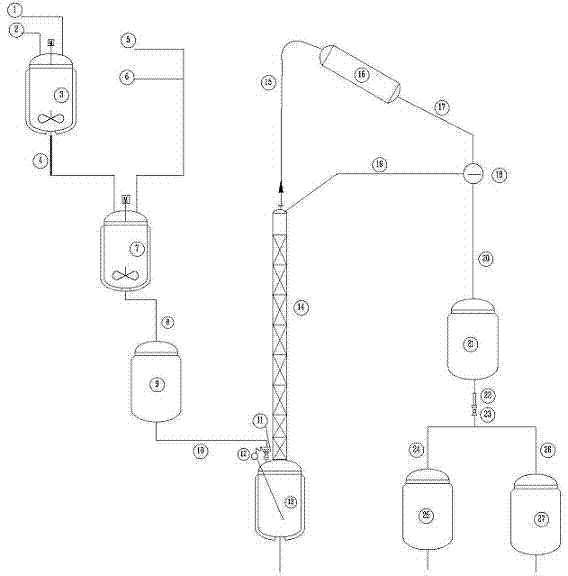

Method used

Image

Examples

Embodiment 2

[0050] No pretreated industrial hydrochloric acid as chlorinating agent: in this embodiment, except that 100 ml of reagent hydrochloric acid is replaced with 110 ml of industrial hydrochloric acid containing HCL34% without pretreatment during initial charging, and then 330 ml is replaced with 350 ml of industrial hydrochloric acid without pretreatment Reagent hydrochloric acid, and when premixed material is added dropwise continuously, replace reagent hydrochloric acid with industrial hydrochloric acid without pretreatment, other preliminary conditions such as reaction device, operation steps, process parameters are all similar to embodiment 1, but in continuous feeding After only 36 hours of continuous separation of the product, the reaction bottle has carbonized slag sticking to the wall, and the bottom of the bottle has frequent bumping due to heat accumulation of viscous material, and the reaction cannot continue, so no pretreatment is performed. The industrial hydrochloric...

Embodiment 3

[0052] Pretreatment of industrial hydrochloric acid: In a 5000ml three-neck reaction bottle equipped with mechanical stirring, thermometer and reflux condenser, add 5000ml of industrial hydrochloric acid containing 34% HCL and 100 (g) sodium dihydrogen phosphite to be treated, and control the temperature by heating in a water bath Stirring and reacting for 100 minutes at a temperature of 55±3° C. can be used as the chlorinating agent in the process of the present invention.

[0053] [29] Example 4

[0054] Pretreated industrial hydrochloric acid as one of the chlorinating agents: in this embodiment, except that the industrial hydrochloric acid after pretreatment is used in Example 3 to replace the unpretreated industrial hydrochloric acid, other previous conditions are similar to those in Example 2 , but after the cumulative time of the continuous reaction reached 252 hours, the reaction rate gradually slowed down due to the accumulation of a certain amount of viscous cros...

Embodiment 5

[0056]Pretreated industrial hydrochloric acid as the second chlorinating agent: add 2mol glycerin, 25 (g) sebacic acid, 15 (g) calcium chloride and 110ml of the industrial hydrochloric acid pretreated in Example 3 respectively in a 500ml glass beaker , stir with a glass rod until the solids are completely dissolved, add the above-mentioned prepared mixture into a 250ml three-necked reaction bottle equipped with a precision fractionation device, a constant pressure dropping funnel and a thermometer, then heat and react under total reflux for 26 hours, then Adjust the reflux ratio to about 2 / 3, and add dropwise 350ml of industrial hydrochloric acid after pretreatment in Example 3, and control the temperature of the reaction solution at 130±5°C. The pre-mixed material of industrial hydrochloric acid after pretreatment (the molar ratio of glycerol to HCL is 1:2.3), the temperature of the reaction solution is continued to be controlled at 130±5°C, and the reflux ratio is gradually r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com