Preparation method and product of nanocellulose crystal/polyaniline composite material

A technology of nanocellulose and composite materials, which is applied in the field of in-situ preparation of nanocellulose crystals/polyaniline composite materials, can solve the problems of poor experimental repeatability, harsh experimental conditions, and restrictions on the wide application of composite materials. Achieve the effect of simple operation, low production cost and renewable cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of cellulose lyotropic cholesteric liquid crystal: Weigh 10 g of microcrystalline cellulose, measure 175 ml of 64% concentrated sulfuric acid, stir and react at 45°C for 3 hours, add a large amount of distilled water, dilute and reduce the suspension temperature to terminate the reaction; then centrifuge the obtained mixed solution with a centrifuge, discard the supernatant, and wash the lower layer of turbid liquid with distilled water, then centrifuge again and discard the supernatant, this step is repeated 1-6 times to obtain nanofibers then carry out dialysis to remove excess acid in the suspension, so that the solution outside the dialysis bag is neutral; then evaporate and concentrate the dialysis suspension under natural conditions, and when the concentration reaches the critical concentration, cellulose bile Steroidal liquid crystal.

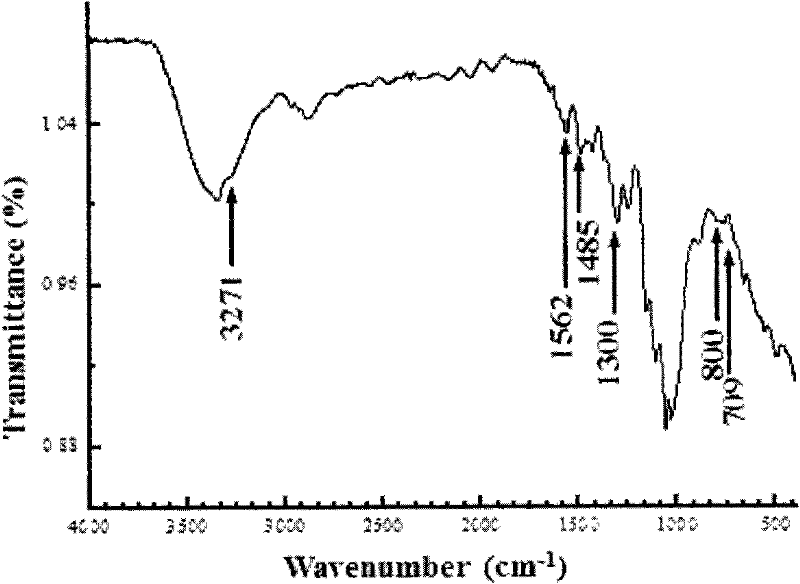

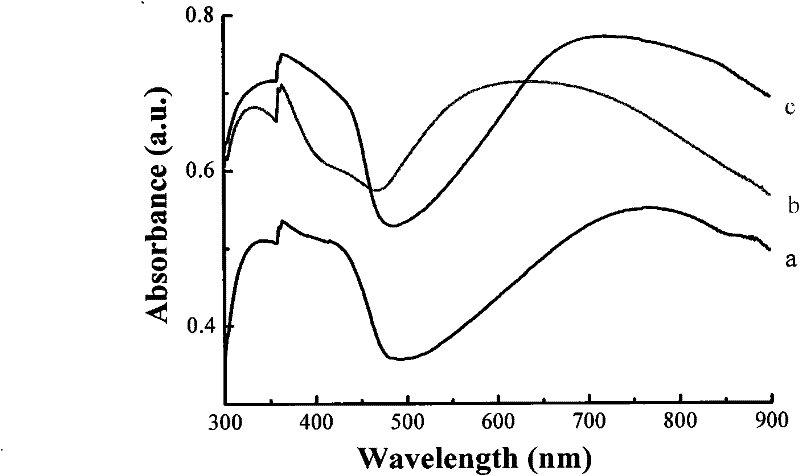

[0023] (2) Preparation of nanocellulose crystal / polyaniline composite material: In this example, the conjugated ...

Embodiment 2

[0025] The acid used in step (1) is 2.5M hydrochloric acid, after reacting for 30min-3h, then post-treat with 64% concentrated sulfuric acid. In step (2), the aniline / HCl solution is firstly added to the cellulose cholesteric liquid crystal suspension, and then the obtained mixed solution is added to the APS / HCl. All the other steps are the same as in Example 1.

Embodiment 3

[0027] In the step (1), the sulfuric acid hydrolysis reaction temperature is 75° C., and the reaction time is 30 minutes. The method of concentration is osmotic compression. Used the 5.8g / L cellulose cholesteric liquid crystal suspension of 50ml in the step (2), all the other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com