Optical filter material of multifunctional protective face mask and preparation method thereof

A technology of protective masks and optical filters, applied in optical filters, chemical instruments and methods, optics, etc., can solve problems such as unsatisfactory and difficult, and achieve the effect of improving the cut-off effect

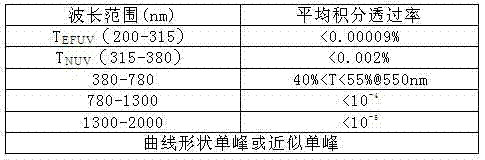

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of the present invention comprises the steps of:

[0017] Step 1, preparing optical glass, its components and weight percentages are: sodium oxide 16-17%, diboron trioxide 5-6%, cerium oxide 5-6%, neodymium oxide 1.2-1.4%, tin protochloride 2.5% -3%, iron powder 2.3-3%, the balance is silicon dioxide;

[0018] Manually pick out the glass water prepared according to the above components, press it into a plate with a thickness of 1.8-2.2mm with double rollers, put the plate into a furnace with a furnace temperature of 480-520°C for annealing treatment, and then process it according to the specified size Cut out of the furnace, and finally grind and polish;

[0019] Step 2, coating the plate after grinding and polishing, the coating layers are zinc sulfide layer, silver layer, zinc sulfide layer, silver layer, zinc sulfide layer, silver layer, zinc sulfide layer and aluminum oxide layer.

[0020] The thickness of each coating layer in the coating l...

Embodiment 1

[0024] The steps of the preparation method of the present invention are as follows:

[0025] Step 1, prepare optical glass, its composition and percentage by weight are: sodium oxide 16%, diboron trioxide 5%, cerium oxide 5%, neodymium oxide 1.2%, tin protochloride 2.5%, iron powder 2.3%, the remaining The amount is silicon dioxide;

[0026] Manually pick out the glass water prepared according to the above components, press it into a 2mm thick plate with double rollers, put the plate into a furnace with a furnace temperature of 500°C for annealing treatment, and then release it according to the specified size after 24 hours cutting, and finally grinding and polishing;

[0027] Step 2, coating the plate after grinding and polishing, the coating layers are zinc sulfide layer, silver layer, zinc sulfide layer, silver layer, zinc sulfide layer, silver layer, zinc sulfide layer and aluminum oxide layer.

[0028] The thickness of each coating layer in the coating layer is: zinc su...

Embodiment 2

[0032] The steps of the preparation method of the present invention are as follows:

[0033] Step 1, first prepare optical glass, its composition and percentage by weight are: sodium oxide 17%, diboron trioxide 6%, cerium oxide 6%, neodymium oxide 1.4%, tin protochloride 3%, iron powder 3%, The balance is silicon dioxide;

[0034] Manually pick out the glass water prepared according to the above components, press it into a 1.8mm thick plate with double rollers, put the plate into a furnace with a furnace temperature of 480°C for annealing treatment, and after 24 hours, proceed according to the specified size. Cut out of the furnace, and finally grind and polish;

[0035] Step 2, coating the plate after grinding and polishing, the coating layers are zinc sulfide layer, silver layer, zinc sulfide layer, silver layer, zinc sulfide layer, silver layer, zinc sulfide layer and aluminum oxide layer.

[0036] Zinc sulfide layer: 110nm; silver layer: 30nm; zinc sulfide layer: 75nm; s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com