A kind of solar cell structure and preparation method thereof

A solar cell and battery technology, applied in the field of solar energy, can solve the problems of poor anti-reflection effect, unfavorable cell efficiency, and improvement, and achieve the effects of increasing light intake, reducing short-wave absorption, and optimizing optical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

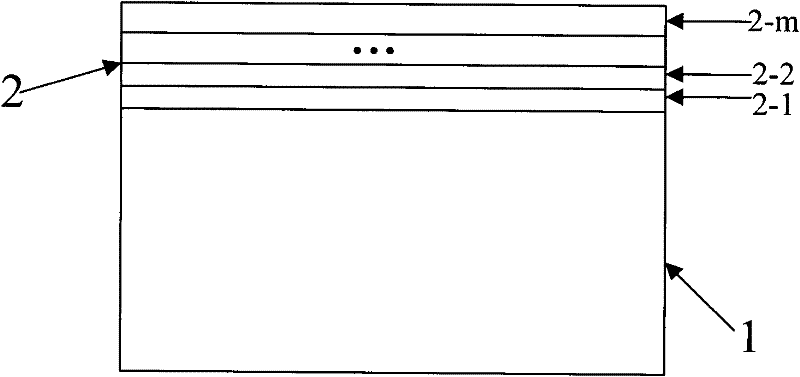

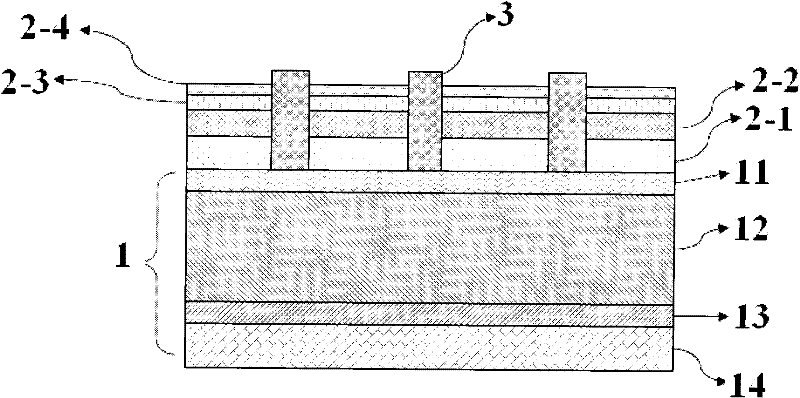

[0040] Such as figure 2 As shown, the solar cell structure of the present embodiment includes a Si battery substrate 1, and a SiNx anti-reflection passivation layer 2 is arranged on the light-facing surface of the battery substrate 1, and also includes a fired SiNx anti-reflection passivation layer 2, which is connected with the battery. Front contact electrode 3 for ohmic contact with substrate 1;

[0041] Wherein, the Si battery substrate 1 includes a P-type region 10 and an N-type region 11, and a P+ back surface field 13 and a back contact electrode 14 are formed on the back side of the Si battery substrate;

[0042] The SiNx anti-reflection passivation layer 2 includes a 4-layer film structure, along the battery substrate 1 from bottom to top are the first layer of film structure 2-1, the second layer of film structure 2-2, and the third layer of film structure 2-3 and the fourth membrane structure 2-4;

[0043] Among them, the thickness of the first film structure 2-1...

Embodiment 2

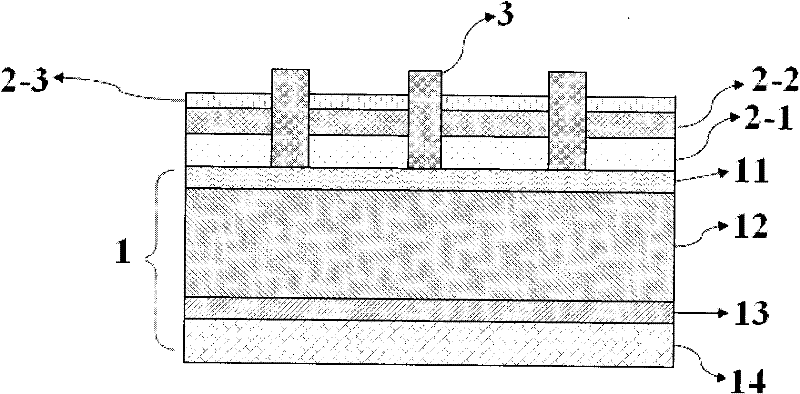

[0046] Such as image 3 As shown, the solar cell structure of the present embodiment includes a Si battery substrate 1, and a SiNx anti-reflection passivation layer 2 is arranged on the light-facing surface of the battery substrate 1, and also includes a fired SiNx anti-reflection passivation layer 2, which is connected with the battery. Front contact electrode 3 for ohmic contact with substrate 1;

[0047] Wherein, the Si battery substrate 1 includes a P-type region 10 and an N-type region 11, and a P+ back surface field 13 and a back contact electrode 14 are formed on the back side of the Si battery substrate;

[0048] The SiNx anti-reflection passivation layer 2 includes a three-layer film structure, which is the first layer film structure 2-1, the second layer film structure 2-2, and the third layer film structure 2-3 from bottom to top along the battery substrate 1. ;

[0049] Among them, the thickness of the first film structure 2-1 is about 77nm, and the refractive in...

Embodiment 3

[0072] This embodiment is a preparation method for the solar cell structure provided in Embodiment 1, as shown in Figure 5, wherein Figure 5(a) is a process flow diagram of this embodiment, and Figure 5(b) is the same as Figure 5 (a) The corresponding implementation effect diagram of the technological process, including the following steps:

[0073] S21, removing the damaged layer on the surface of the P-type silicon substrate, forming an anti-reflection surface structure and chemical cleaning.

[0074] See S21' for the implementation effect of this step.

[0075] S22, in POCl 3 The diffusion of the n-type layer is carried out in the atmosphere.

[0076] That is, an n-type layer is formed on the surface of the p-type silicon substrate, thereby producing a PN junction. The implementation effect of this step is shown in S22'.

[0077] S23, removing the peripheral PN junction.

[0078] In this step, plasma is used to etch the edge of the silicon wafer to prevent conduction on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com