Method for preparing ceramic-based composite material environment barrier coating by laser cladding

A composite material, laser cladding technology, applied in the field of coating, to achieve the effect of low residual stress, high efficiency and small thermal distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

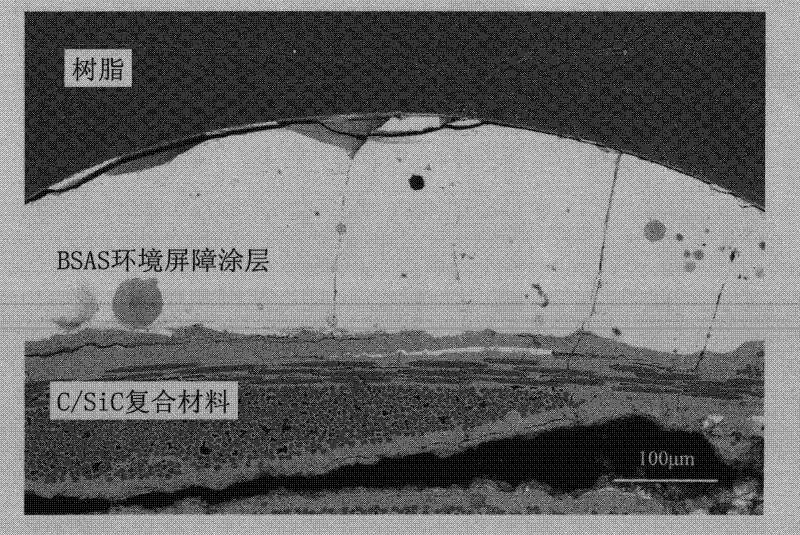

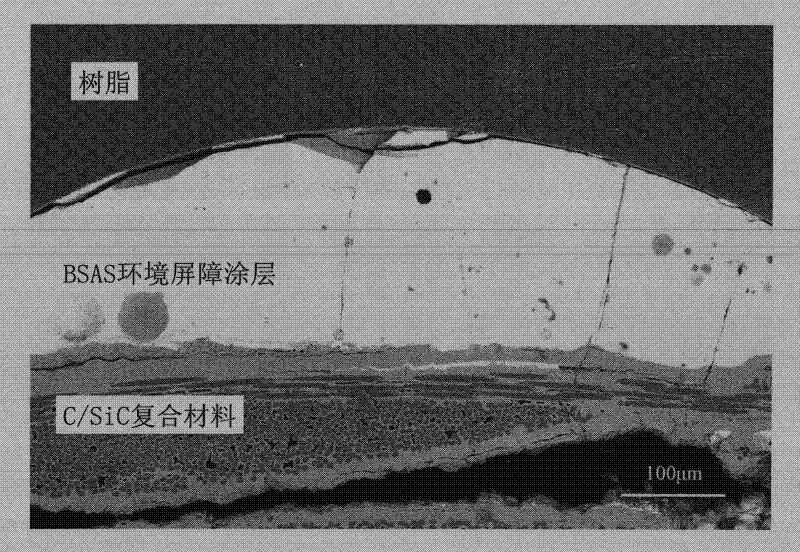

[0024] Example 1: C / SiC surface laser cladding BSAS coating

[0025] 1. Substrate preparation: In this experiment, C / SiC was selected as the substrate, and C / SiC was made into a material with a size of 40×5×3.5mm as the substrate material for laser cladding of the coating.

[0026] 2. Powder preparation: BaCO 3 ,,SrCO 3 , Al(OH) 3 and SiO 2 Mix at a molar ratio of 1:1:4:4, add distilled water and wet-mix on a ball mill for 4 hours, place the mixed raw materials in a freeze dryer for freeze-drying, and then place them in a high-temperature furnace for heat treatment at 1100°C, and then heat-treat The final powder was put into a ball mill jar, mixed with distilled water for 4 hours, and dried to obtain the desired Ba 0.5 Sr 0.5 Al 2 Si 2 o 8 Powder.

[0027] 3. Slurry preparation: In this example, polyvinyl acetal (PVB) was selected as the dispersant and binder, and absolute ethanol was used as the solvent. Will make Ba 0.5 Sr 0.5 Al 2 Si 2 o 8 Powder, polyvinyl a...

Embodiment 2

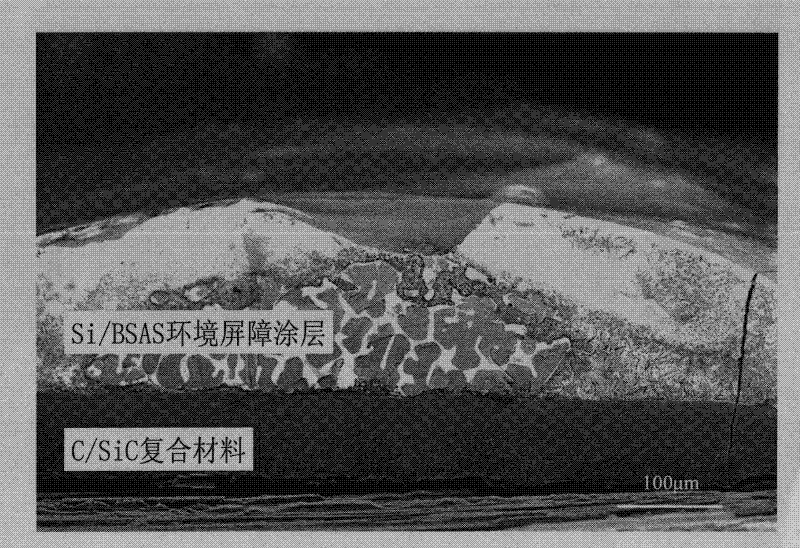

[0030] Example 2: C / SiC surface laser cladding Si / BSAS composite coating

[0031] Step 1-2 is with embodiment 1;

[0032] 3 Slurry preparation: In this example, polyvinyl acetal (PVB) was used as a binder, and absolute ethanol was used as a solvent.

[0033] Si and BSAS were made into slurry respectively, and the preparation method was the same as in Example 1. Now, the Si slurry was evenly coated on the surface of the composite material as an intermediate layer, and dried in an oven at 70°C, and then the BSAS slurry was evenly coated Brush the surface of the material coated with Si slurry as the outermost layer, and place it in an oven to dry at 70°C.

[0034] 4 Laser cladding: This example uses 8kW CO 2 Continuous laser for laser cladding. Place the pre-coated / SiC on the workbench under the laser beam to prepare the Si / BSAS environmental barrier coating. The selected laser cladding process parameters are: laser power 100W; scanning speed 150mm / min; spraying distance 5-1...

Embodiment 3

[0036] Example 3: Laser cladding Sc on C / SiC surface 2 Si 2 o 7涂 layer:

[0037] Step 1 is the same as in Example 1.

[0038] 2 Powder preparation: the selected Sc(NO 3 ) 3 ·6H 2 O, the amount of ethyl silicate (TEOS), ethanol and water is in a molar ratio of 1:1:4:4, a certain amount of ethyl silicate (TEOS) is dissolved in a corresponding amount of ethanol, and fully stirred for a certain period of time. Add Sc(NO 3 ) 3 ·6H 2O was completely dissolved, then distilled water was added and stirred for 12h. The prepared sol was heated and dried in a dryer. Then put it in a high-temperature furnace for heat treatment at 1050 ° C, then put the heat-treated powder into a ball mill jar, add distilled water to wet mix for 4 hours, and dry to obtain the desired Sc 2 Si 2 o 7 Powder.

[0039] 3 Slurry preparation: In this example, polyvinyl acetal (PVB) was selected as the dispersant and binder, and absolute ethanol was used as the solvent. Sc will be produced 2 Si 2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com