Integral macroporous alumina and preparation method thereof

A macroporous alumina, monolithic technology, applied in alumina/aluminum hydroxide and other directions, can solve the problems of high preparation cost, large amount of template, monomer toxicity of template, etc., and achieves simple preparation process, low cost, and ease of use. removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

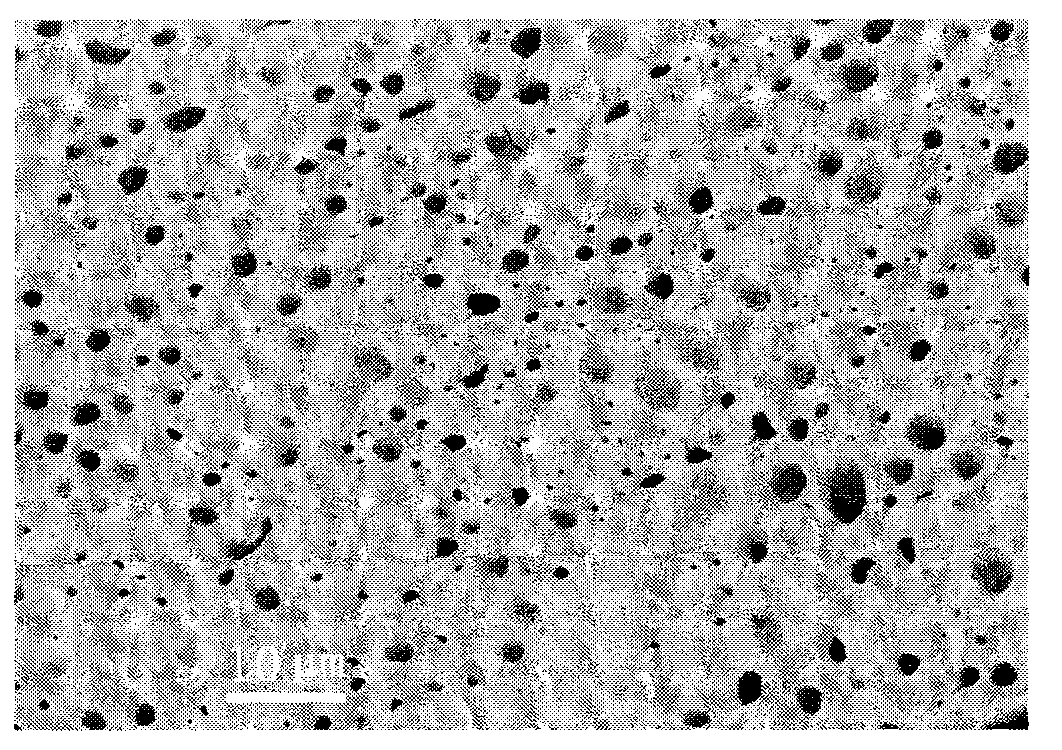

Image

Examples

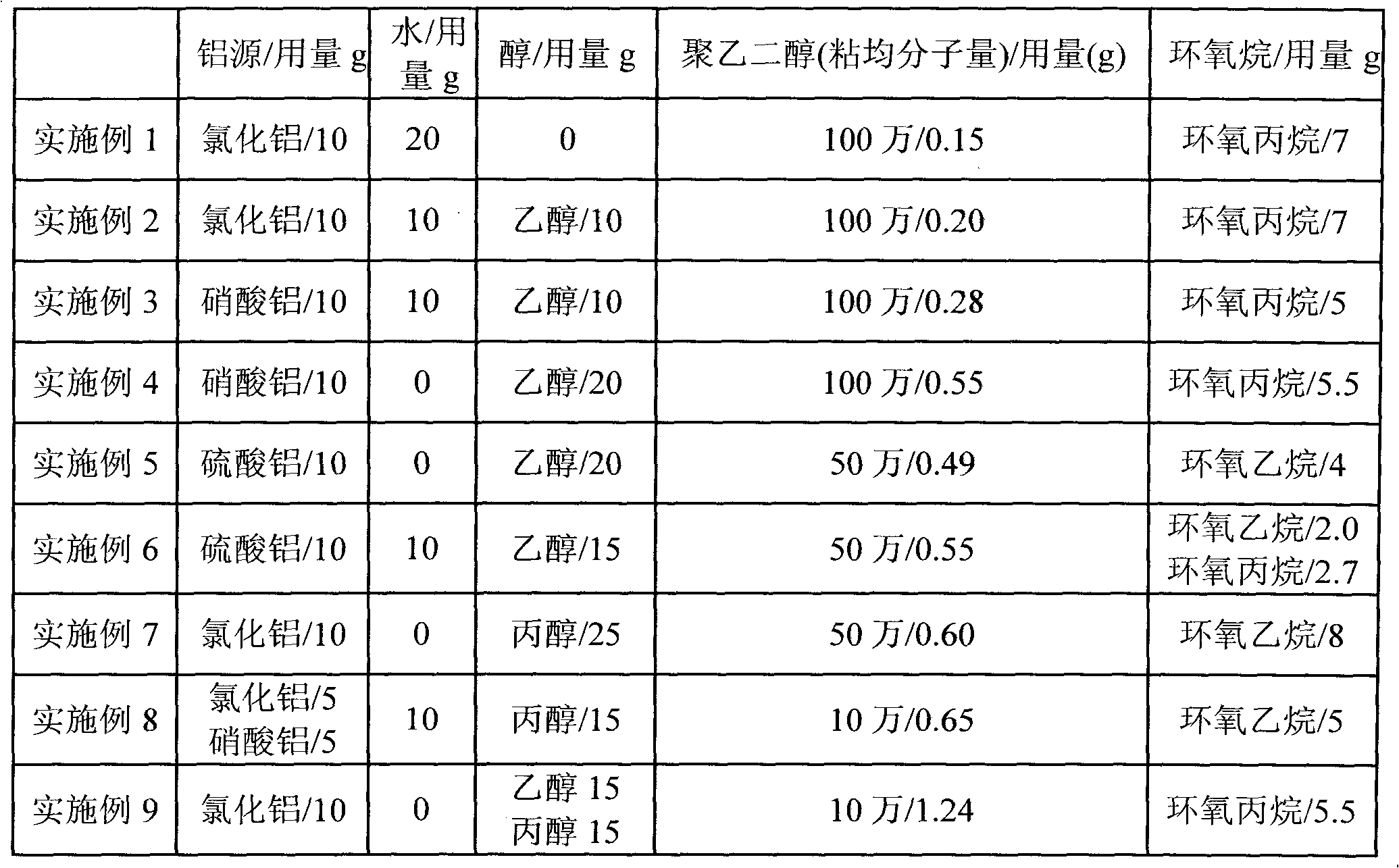

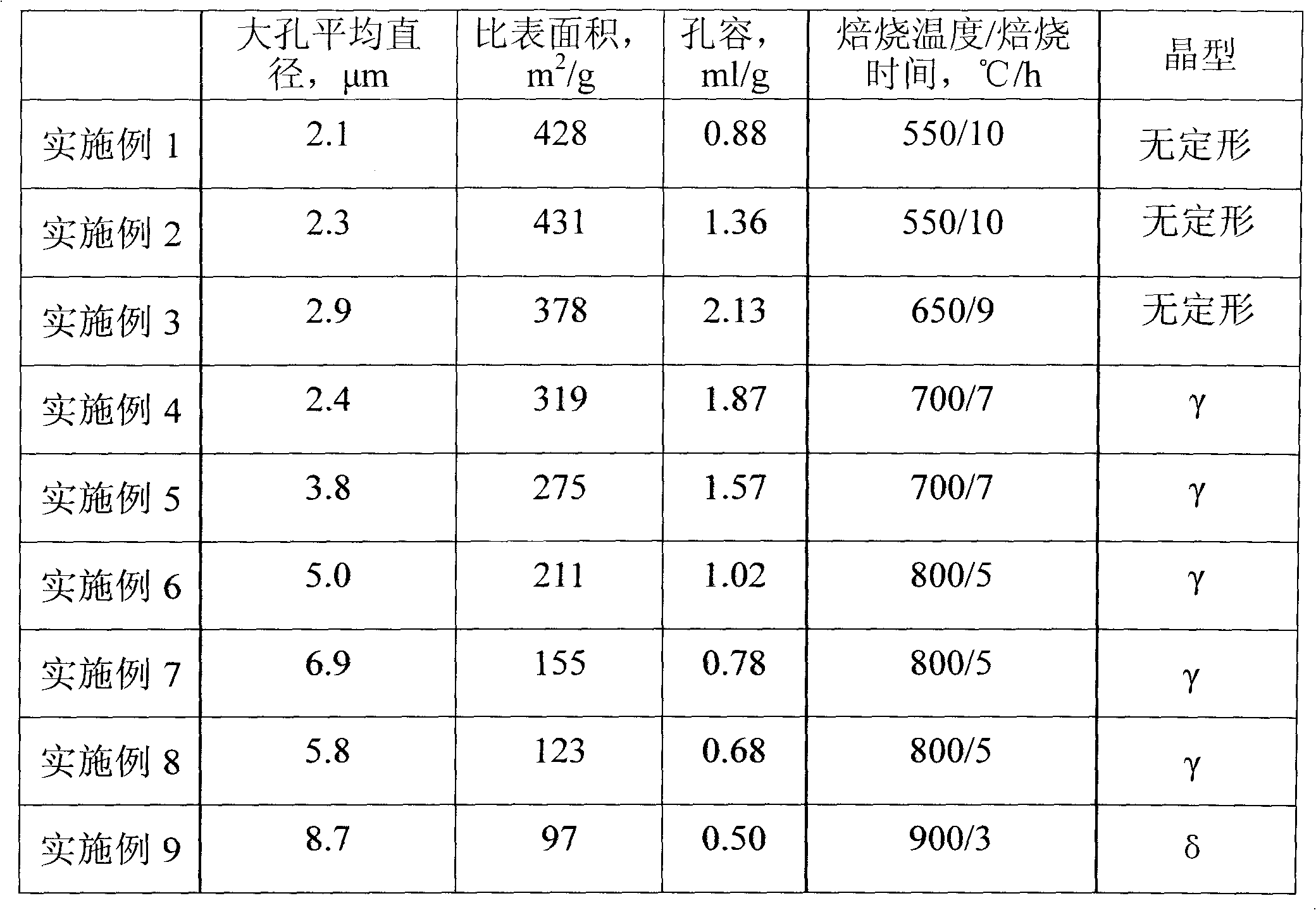

Embodiment 1

[0027] After fully dissolving 10 grams of aluminum chloride, 20 grams of water, and 0.15 grams of polyethylene glycol (viscosity average molecular weight of 1 million) and mixing uniformly, 0.15 grams of propylene oxide was added to the above mixture and mixed uniformly therewith. The resulting mixed product was aged at 35°C for 24 hours, then soaked in ethanol for 24 hours after aging, and after removing the liquid phase, the vacuum degree was measured by gauge pressure: at a vacuum degree of -0.075MPa and a drying temperature of 25°C, dry for 5 After 1 hour, the temperature was raised to 550°C at a heating rate of less than 50°C / min, kept at a constant temperature for 10 hours, and then cooled to room temperature to obtain the monolithic macroporous alumina described in the present invention. The main synthetic data are listed in Table 1, and the product properties are listed in Table 2.

Embodiment 2

[0029] Carry out this example according to the method for embodiment 1, used raw material and consumption are listed in table 1. The resulting mixed product was aged at 25°C for 24 hours, then soaked in ethanol for 24 hours after aging, and after removing the liquid phase, the vacuum degree was measured by gauge pressure: at a vacuum degree of -0.090MPa and a drying temperature of 25°C, dry for 5 After 1 hour, the temperature was raised to 550°C at a heating rate of less than 50°C / min, kept at a constant temperature for 10 hours, and then cooled to room temperature to obtain the monolithic macroporous alumina of the present invention. The properties of the product are listed in Table 2.

Embodiment 3

[0031] Carry out this example according to the method for embodiment 1, used raw material and consumption see table 1, and product property is listed in table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com