Composite material Li3V2(PO4)3/Li4Ti5O12 and preparation method thereof

A composite material and technology of preparation steps, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as unsatisfactory rate and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

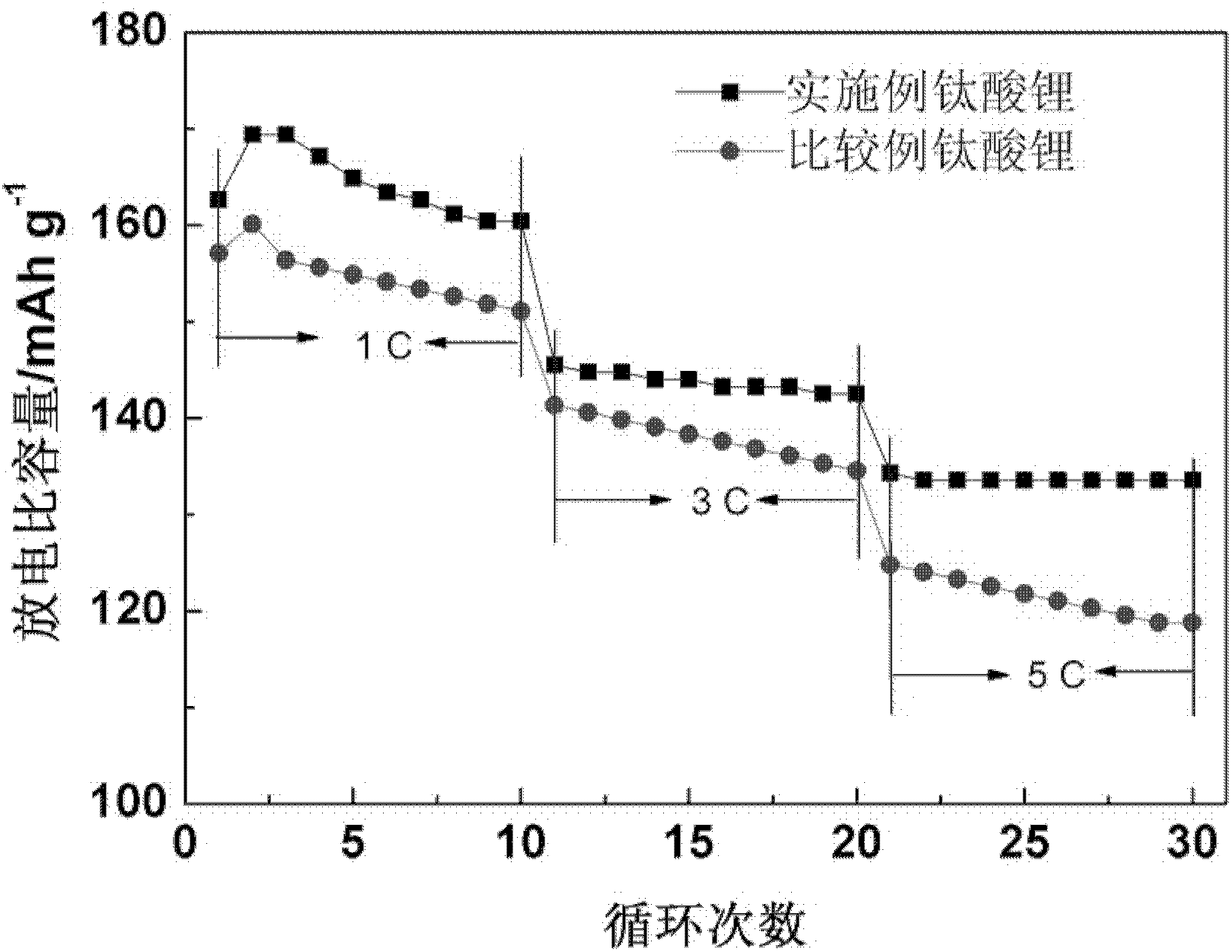

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of Li 3 V 2 (PO 4 ) 3 / Li 4 Ti 5 o 12 Composite materials, including spinel-type Li in parts by mass 4 Ti 5 o 12 99 parts, monoclinic Li 3 V 2 (PO 4 ) 3 for 1 serving.

[0037] Li 3 V 2 (PO 4 ) 3 / Li 4 Ti 5 o 12 The preparation method of composite material comprises the following specific steps:

[0038] Step A, preparation of monoclinic Li 3 V 2 (PO 4 ) 3

[0039] a. Lithium hydroxide (LiOH·H 2 O), vanadium pentoxide (V 2 o 5 ) and phosphoric acid (H 3 PO 4 ) was dissolved in 400ml deionized water under magnetic stirring to form solution I, in which, calculated according to the amount of substance,

[0040] b. Dissolve 1.5g of citric acid in 70ml of deionized water under the condition of ultrasonic dispersion to obtain solution II;

[0041] c. In a water bath at 70°C, under the condition of vigorous stirring, slowly add solution II to solution I dropwise to obtain solution III;

[0042] d. React the solution III obtained in st...

Embodiment 2

[0056] A kind of Li 3 V 2 (PO 4 ) 3 / Li 4 Ti 5 o 12 Composite materials, including spinel-type Li in parts by mass 4 Ti 5 o 12 99 parts, monoclinic Li 3 V 2 (PO 4 ) 3 for 1 serving.

[0057] Li 3 V 2 (PO 4 ) 3 / Li 4 Ti 5 o 12 The preparation method of composite material comprises the following specific steps:

[0058] Step A, preparation of monoclinic Li 3 V 2 (PO 4 ) 3

[0059] a. Lithium acetate (CH 3 COOLi·2H 2 O), ammonium metavanadate (NH 4 VO 3 ) and phosphoric acid (H 3 PO 4 ) was dissolved in 350ml deionized water under magnetic stirring to form solution I, in which calculated according to the amount of substance,

[0060] b. Dissolve 2.7g of glycine in 100ml of deionized water under the condition of ultrasonic dispersion to obtain solution II;

[0061] c. In a water bath at 70°C, under the condition of vigorous stirring, slowly add solution II to solution I dropwise to obtain solution III;

[0062] d. React the solution III obtaine...

Embodiment 3

[0076] A kind of Li 3 V 2 (PO 4 ) 3 / Li 4 Ti 5 o 12 Composite materials, including spinel-type Li in parts by mass 4 Ti 5 o 12 99.5 parts, monoclinic Li 3 V 2 (PO 4 ) 3 0.5 parts.

[0077] Li 3 V 2 (PO 4 ) 3 / Li 4 Ti 5 o 12 The preparation method of composite material comprises the following specific steps:

[0078] Step A, preparation of monoclinic Li 3 V 2 (PO 4 ) 3

[0079] a. Lithium hydroxide (LiOH·H 2 O), ammonium metavanadate (NH 4 VO 3 ) and ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) was dissolved in 400ml deionized water under magnetic stirring to form solution I, in which, calculated according to the amount of substance,

[0080] b. Dissolve 4.2g of oxalic acid in 80ml of deionized water under the condition of ultrasonic dispersion to obtain solution II;

[0081] c. In a water bath at 70°C, under the condition of vigorous stirring, slowly add solution II to solution I dropwise to obtain solution III;

[0082] d. React the solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com