Copper-based polymer hybrid catalyst used in selective hydrogenation of acetylene and preparation method thereof

A selective hydrogenation and polymer technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, hydrogenation hydrocarbon production, etc., can solve high production costs, low acetylene removal rate, environmental problems Pollution and other issues, to achieve the effect of wide operating window and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

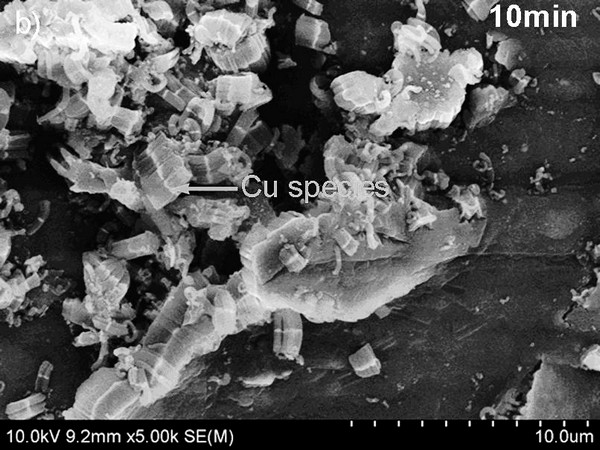

[0018] The metered copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) The blue solution obtained by dissolving in 10 ml of deionized water was added dropwise to 3 g of SiO 2 In medium, stir quickly to evenly impregnate. Aged in the air for 12 hours, then dried in an oven at 120°C for 12 hours, ground, and fired at 500°C for 3 hours to obtain powdered Cu / SiO 2 catalyst. The catalysts with copper loadings of 30 wt% and 10 wt% were named A-1 and A-2, respectively.

Embodiment 2

[0020] The metered copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) and a measured aqueous solution of tetraaminopalladium nitrate were dissolved in 10 ml of deionized water, and the resulting solution was added dropwise to 3 g of SiO 2 In medium, stir quickly to evenly impregnate. Aged in the air for 12 hours, then dried in an oven at 120°C for 12 hours, ground, and fired at 500°C for 3 hours to obtain Cu-Pd / SiO 2 powder catalyst. The loading of copper was 10 wt%, and the loading of palladium was 0.3 wt% and 0.5 wt%, named as B-1 and B-2, respectively.

Embodiment 3

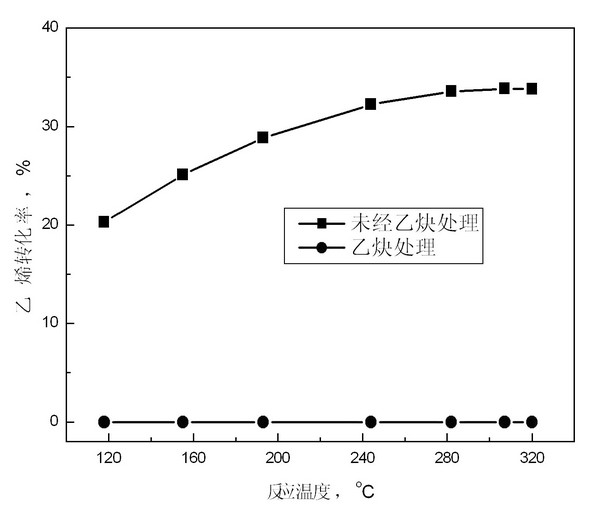

[0022] The catalytic hydrogenation reaction was carried out in a quartz tube reactor with an inner diameter of 8 mm. Weigh a certain amount of catalyst and load it into the constant temperature zone of the reactor, and both ends of the bed are supported by quartz sand. GC-7890F gas chromatograph was used to analyze the composition of reaction raw materials and products. Chromatography adopts FID detector, commercially available Al2O3 chromatographically packed column, the column length is 2 m, and the inner diameter is 0.32 mm. Catalyst performance is described in terms of acetylene conversion and ethylene selectivity.

[0023] 0.1 g of catalyst A-1 was reduced in hydrogen at 300°C for 60 minutes, and then passed through standard gas (2% methane, 1.99% acetylene, 4.01% hydrogen, and the rest of ethylene) and hydrogen for hydrogenation reaction at 300°C, maintaining the standard gas flow The hydrogen flow rate was changed to 50 mL / min, and the effect of hydrogen parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com