Preparation method of star polyacrylamide polymer

A technology of polyacrylamide and acrylamide, which is applied in the field of preparation of star-shaped acrylamide polymers, can solve the problems of small molecular weight, unfavorable industrial production, and impracticality, etc. The effect of strong shear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

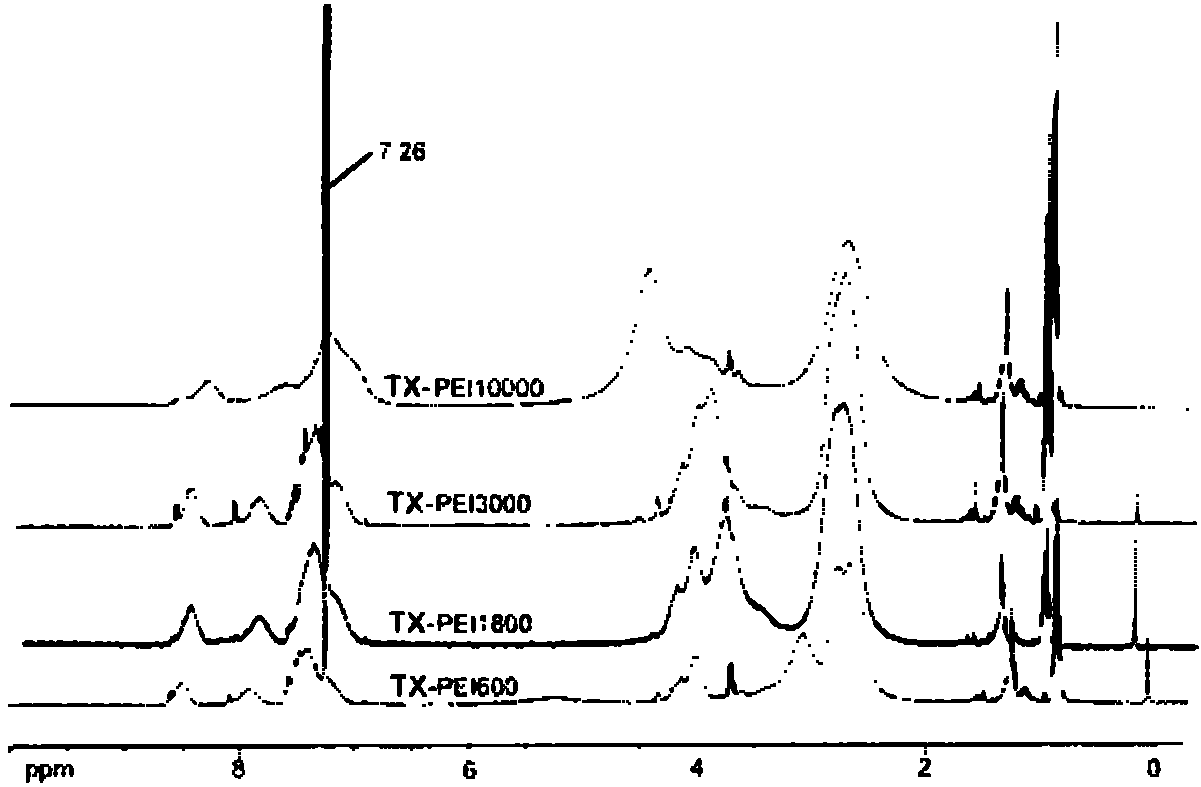

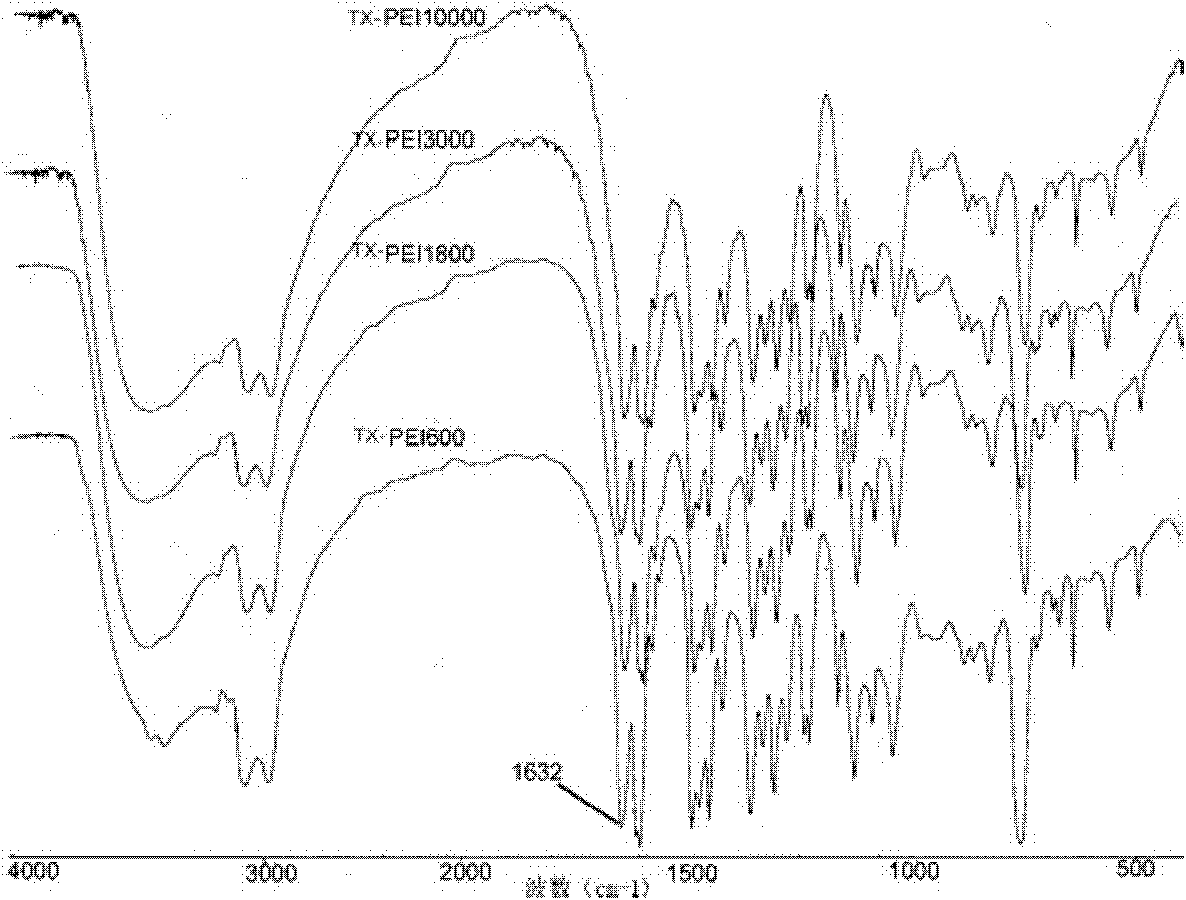

[0046] Preparation of thioxanthone-modified polyethyleneimine shown in embodiment 1, formula (II)

[0047] (1) Preparation of 2-glycidyloxythioxanthone

[0048] Dissolve 16g of thiosalicylic acid in 150mL of concentrated sulfuric acid, stir at room temperature for 10min; slowly add 44g of phenol dropwise, react at room temperature for 1h, then raise the temperature to 80°C for 2h, and let stand overnight. Slowly pour the reaction solution into 1500mL boiling water, and continue to boil for 30 minutes after adding; cool to about 60°C and filter, dry to obtain the intermediate product 2-hydroxythioxanthone. Add 13.68g of 2-hydroxythioxanthone, 21g of anhydrous potassium carbonate, and 100mL of epichlorohydrin into 120mL of toluene, react at 80°C for 12h, then react at 135°C for 12h, filter after the reaction is complete, and spin dry Excess epichlorohydrin and solvent were used, and the residue was extracted with chloroform to obtain 80.5 g of 2-glycidoxythioxanthone.

[0049]...

Embodiment 2

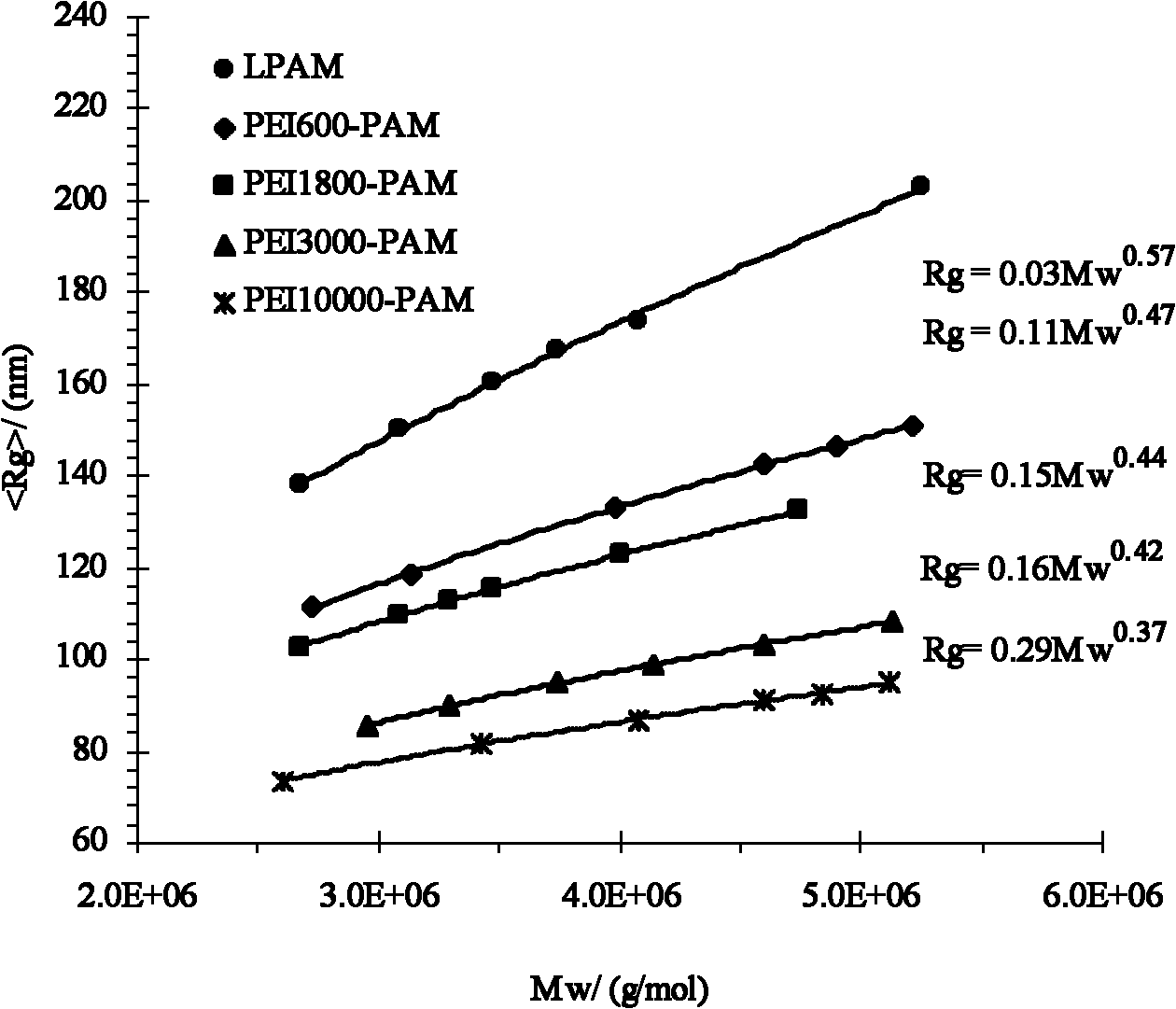

[0056] Embodiment 2, the preparation of star acrylamide homopolymer

[0057] Prepare 100mL of acrylamide aqueous solution with a mass fraction of 30% (containing 30g of acrylamide), pour the reaction solution into a rectangular quartz glass tank (150×90×40mm), add thioxanthone-modified polyethyleneimine (TX- PEI1800) 0.0027g, the concentration of thioxanthone modified polyethyleneimine (TX-PEI1800) is 15×10 -6 mol / L, nitrogen and deoxygenation for 30 minutes, seal the glass tank and place it 15cm above the 500W high-pressure mercury lamp. At this time, the ultraviolet rays pass through the filter ZJB360 and irradiate the reaction solution, and react at 30°C for 30 minutes to obtain star-shaped polyacrylamide The block of homopolymer, shredded, precipitated with absolute ethanol, and dried to obtain star-shaped polyacrylamide homopolymer (PEI1800-PAM) with thioxanthone-modified polyethyleneimine as the core, the reaction conversion rate is 99.6%, its GPC curve as Figure 4 sh...

Embodiment 3

[0060] Embodiment 3, preparation of partially hydrolyzed star polyacrylamide homopolymer

[0061] Prepare 100mL of acrylamide aqueous solution with a mass fraction of 25% (containing 25g of acrylamide), pour the reaction solution into a rectangular quartz glass tank (150×90×40mm), add thioxanthone-modified polyethyleneimine (TX- PEI1800) 0.0018g, the concentration of thioxanthone modified polyethyleneimine (TX-PEI1800) is 10×10 -6 mol / L, nitrogen and deoxygenation for 30 minutes, seal the glass tank and place it 10cm above the 500W high-pressure mercury lamp. At this time, the ultraviolet rays pass through the filter ZJB360 and irradiate the reaction solution, and react at 30°C for 30 minutes to obtain star-shaped polyacrylamide Homopolymer block, cut into pieces, added 70mL of 10wt% NaOH solution, hydrolyzed at 90°C for 3h, precipitated with absolute ethanol, and dried to obtain partially hydrolyzed star polymer with thioxanthone-modified polyethyleneimine as the core. Acryl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| composition ratio | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com