Bridged diamidine-based zinc catalyst and preparation method and application thereof

A catalyst, zinc amidinate technology, applied in the field of transition metal catalysts for lactide polymerization, can solve the problems of PLA limitation, aluminum ion cannot be metabolized, and limit the application of PLA, and achieve the effect of low price, high yield and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

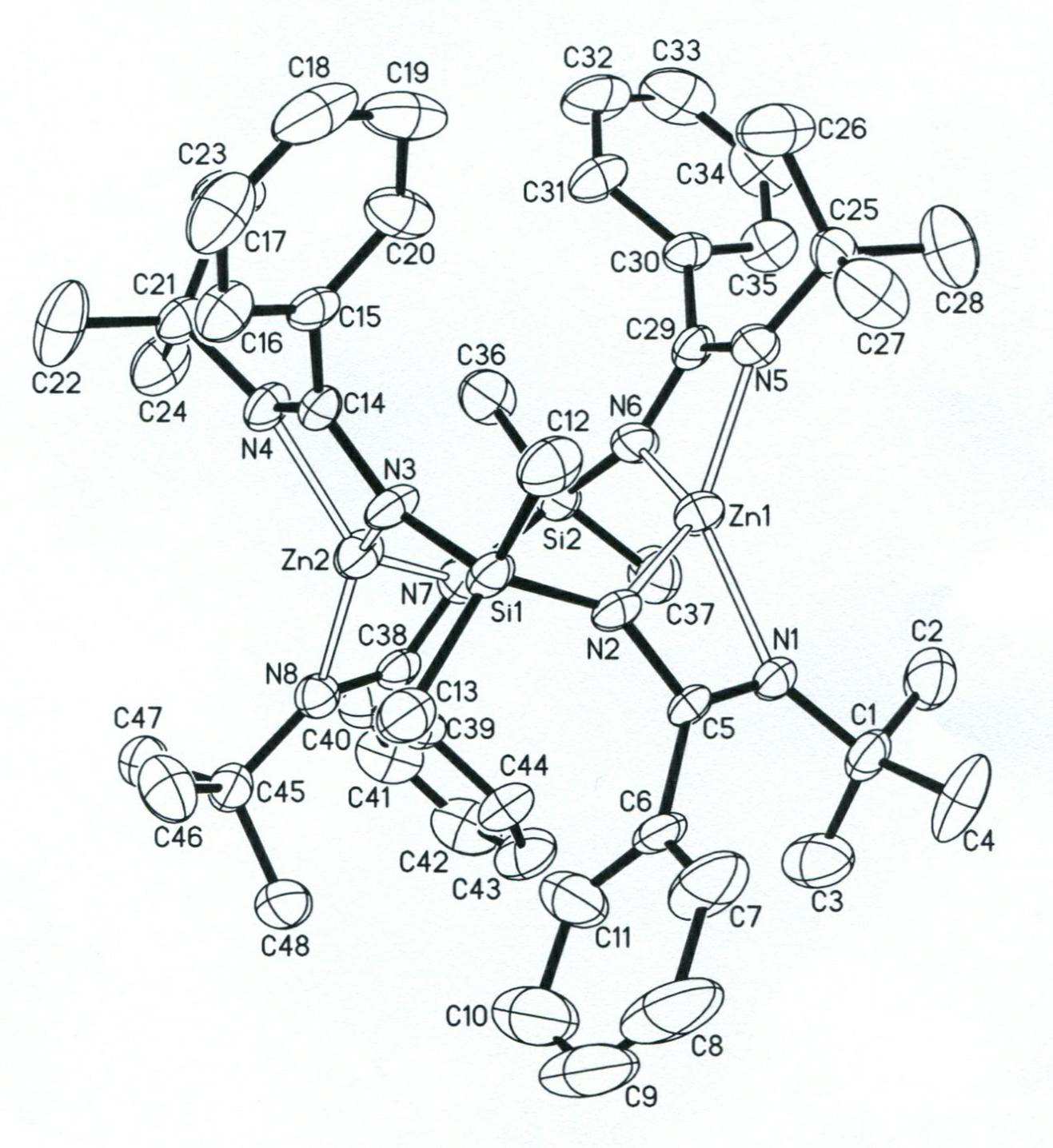

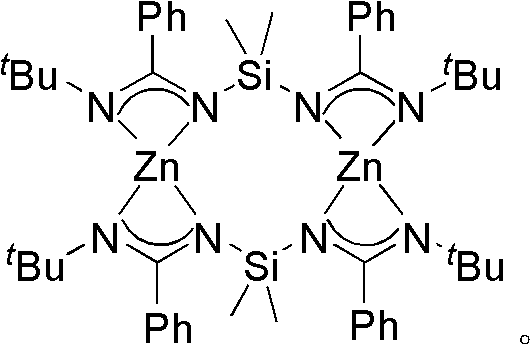

[0014] Preparation and characterization of embodiment 1 catalyst 2a

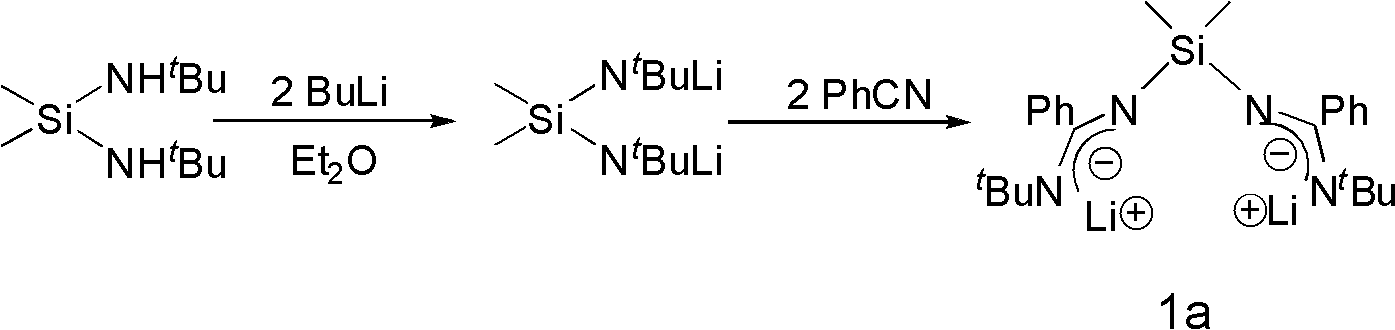

[0015] (1) Preparation of lithium salt

[0016] Under the protection of nitrogen and ice water bath, dimethylsilyl bridged diphenylamine (6.0g, 24.8mmol) was dissolved in ether (200cm 3 ), under stirring, slowly add LiBu n n-hexane solution (2.8mol dm -3 , 17.7cm 3 , 49.6mmol), after the reaction mixture returned to room temperature, continued to stir for 2 hours, cooled the reaction solution to 0°C, and added PhCN (5.06cm 3 , 49.6mmol), after the reaction mixture returned to room temperature, continued to stir for 5 hours, and recrystallized the white solid obtained after the reaction with tetrahydrofuran to obtain a yellow crystalline bridging bis-amidine ligand lithium salt 1a.

[0017] (2) Dissolve the bridged bisamidine lithium compound 1a (2.05g, 2.44mmol) in tetrahydrofuran (ca. 30mL) to obtain a yellow clear liquid, and slowly add anhydrous dichloro Zinc chloride (0.335g, 2.44mmol), after the re...

Embodiment 2

[0022] 1. The preparation of catalyst 2a is the same as in Example 1.

[0023] 2. Lactide polymerization: Dissolve lactide (0.81g, 5.62mmol) in 3% n-butanol in tetrahydrofuran (20mL), and then add bridged bisamidinyl zinc catalyst 2a (0.053g, 0.0562mmol) , the ratio of catalyst to lactide is 1:100, react for 24 hours, drop a few drops of analytically pure hydrochloric acid into the reaction solution to terminate the reaction, then slowly add ethanol to the solution, a large amount of white insoluble matter will appear, after standing Filter and drain the solvent to obtain a colorless transparent jelly, which is polylactic acid product. Conversion rate 84.8%

Embodiment 3

[0025] 1. The preparation of catalyst 2a is the same as in Example 1.

[0026] 2. Lactide polymerization: Dissolve lactide (0.875g, 6.08mmol) in tetrahydrofuran solution (20mL), then add bridged bisamidinyl zinc catalyst 2e (0.057g, 0.0608mmol), catalyst and lactide The ratio is 1:100, react for 24 hours, drop a few drops of analytically pure hydrochloric acid into the reaction solution to terminate the reaction, then slowly add ethanol to the solution, a large amount of white insoluble matter will appear, filter after standing, and drain the solvent to obtain The colorless transparent jelly is a polylactic acid product. Conversion rate 89.8

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com