Preparation method for spherical lithium titanate material

A lithium titanate, spherical technology, applied in the field of preparation of spherical lithium titanate negative electrode material, can solve the problems of high cost, long time, complicated steps, etc., and achieve the effect of uniform particle size and excellent electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Synthesis of spherical titania

[0034] Prepare a titanium sulfate aqueous solution with a concentration of 0.2 mol / liter. Measure 1 liter of the prepared titanium sulfate aqueous solution and 1 liter of n-propanol in a 2 liter reaction vessel, mix well, and then add 10 grams of polyvinylpyrrolidone K30 to fully dissolve them. Put the reaction vessel at a temperature of 80°C, hydrolyze the mixed solution for 100 minutes to obtain spherical titanium dioxide hydrate, then transfer the obtained material to a solid-liquid separator for solid-liquid separation, and wash the solid obtained from solid-liquid separation with deionized water The pH of the product to wash water was 6. Place the resulting solid product in a desiccator to dry, then transfer it to an alumina crucible, raise the temperature in a muffle furnace at a rate of 300°C / hour to a furnace at 700°C, keep the temperature constant for 2 hours, and stop heating , naturally cooled to room temperature in the f...

Embodiment 2

[0040] 1. Synthesis of spherical titania

[0041] Spherical titanium dioxide was prepared under the same conditions as in Example 1.

[0042] 2. Synthesis of spherical lithium titanate

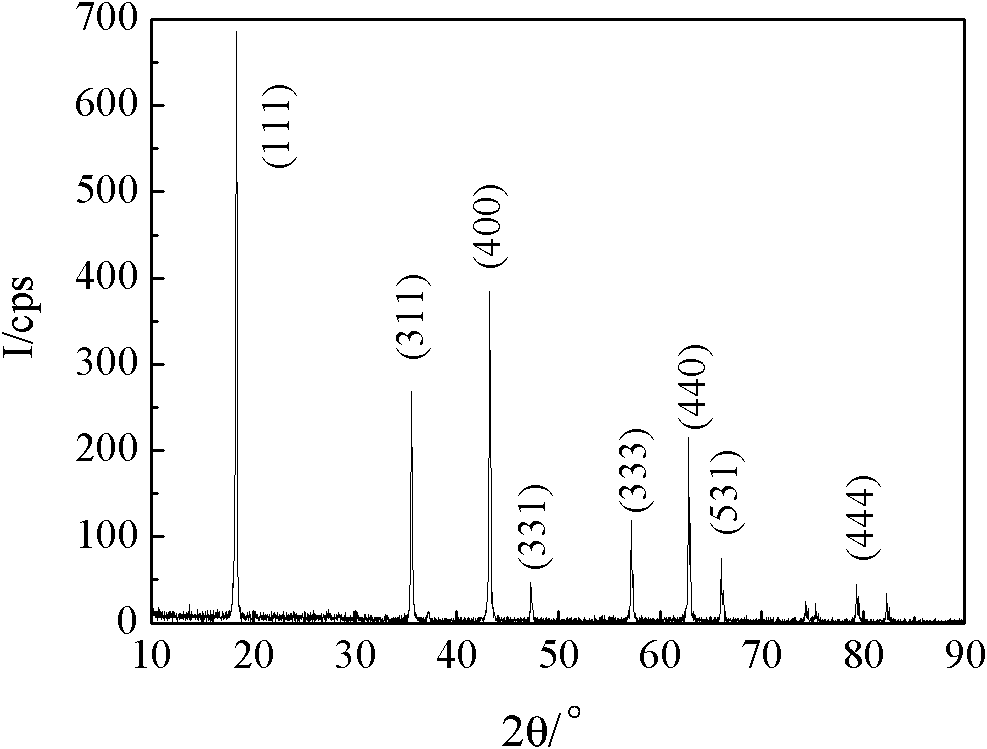

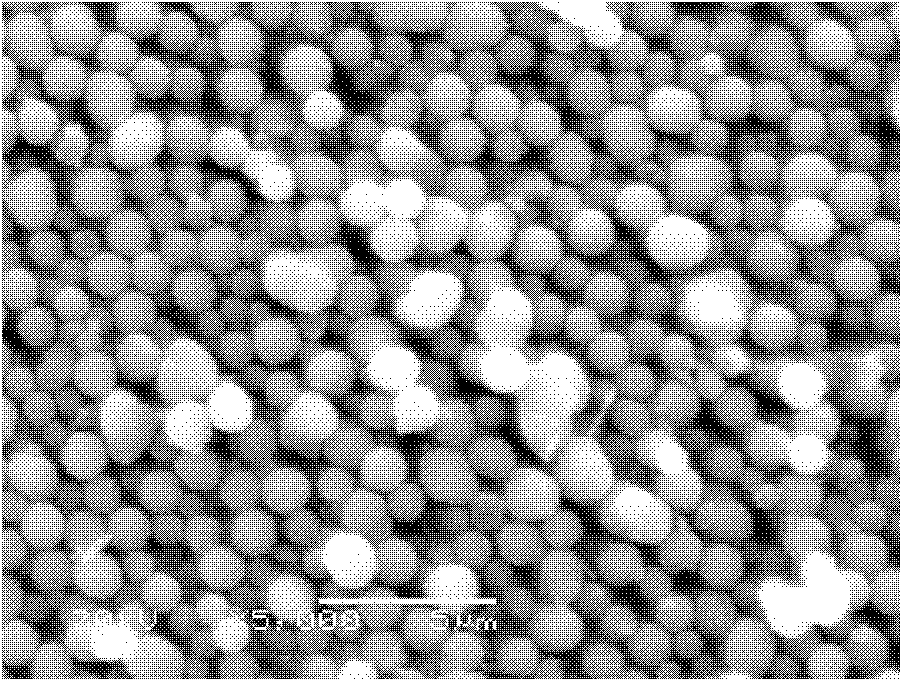

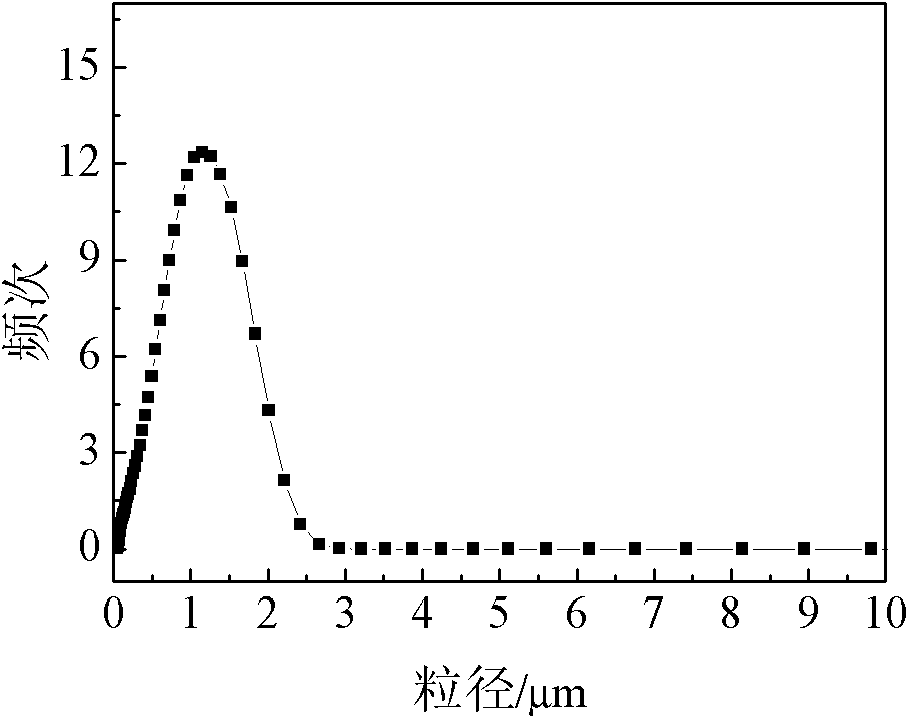

[0043] The heat treatment temperature of 800° C. is replaced by a heat treatment temperature of 850° C., and other conditions are the same as in Example 1. The XRD test shows that the material is lithium titanate with a single spinel structure; the SEM observation shows that the product particles are uniform and spherical; the tap density of the material is 1.2g / cm 3 , by particle size analysis particle D 50 It is about 1.3 μm.

[0044] 3. Electrochemical properties of spherical lithium titanate materials

[0045] The battery was assembled under the same conditions as in Example 1. The charge and discharge voltage is 1.0-2.5V. Under 0.2C current discharge, the discharge specific capacity is about 160mAh / g, the average capacity decay rate per cycle is less than 0.04%, and the discharge spe...

Embodiment 3

[0047] 1. Synthesis of spherical titania

[0048] Spherical titanium dioxide was prepared under the same conditions as in Example 1.

[0049] 2. Synthesis of spherical lithium titanate

[0050] The heat treatment temperature of 800° C. is replaced by a heat treatment temperature of 900° C., and other conditions are the same as in Example 1. The XRD test shows that the material is lithium titanate with a single spinel structure; the scanning electron microscope (SEM) observation shows that the product particles are uniform and spherical; the tap density of the material is 1.2g / cm 3 , by particle size analysis particle D 50 It is about 1.8 μm.

[0051] 3. Electrochemical properties of spherical lithium titanate materials

[0052] The battery was assembled under the same conditions as in Example 1. The charge and discharge voltage is 1.0-2.5V, and the discharge specific capacity is about 155mAh / g under 0.2C current discharge, and the average capacity decay rate per cycle is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com