Method for manufacturing solar battery with selective emitter

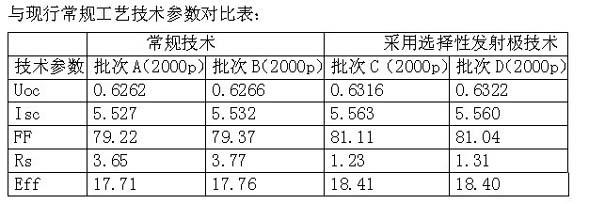

A technology of solar cells and emitters, applied in circuits, electrical components, climate sustainability, etc., can solve the problems of battery open circuit voltage and short circuit current reduction, low photon absorption efficiency, fill factor reduction, etc., to achieve short circuit current improvement, Improve photon response and reduce internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: A kind of preparation method of selective emitter solar cell is carried out according to the following steps:

[0023] (1) When printing electrodes, mix high-concentration phosphorus slurry into the electrode slurry:

[0024] First, evenly coat the surface of the silicon wafer with 5% phosphoric acid aqueous solution. The thickness of the phosphoric acid aqueous solution is 40 μm. The phosphoric acid aqueous solution is diffused on the surface of the silicon wafer. Doped with phosphorus slurry containing 30% phosphorus, after sintering the electrode, a highly doped area square is obtained in the electrode contact area, and the resistance of the highly doped area square is 15Ω, forming an ohmic contact;

[0025] (2) Diffusion in the atmosphere of phosphorus oxychloride after printing high-concentration phosphorous slurry in the electrode grid linear screen:

[0026] ①. At the beginning of the diffusion, the POCl is introduced 3 gas:

...

Embodiment 2

[0033] A preparation method for a selective emitter solar cell, which comprises the following steps:

[0034] (1) When printing electrodes, mix high-concentration phosphorus slurry into the electrode slurry:

[0035]First, evenly coat the surface of the silicon wafer with 5% phosphoric acid aqueous solution. The thickness of the phosphoric acid aqueous solution is 45 μm. The phosphoric acid aqueous solution is diffused on the surface of the silicon wafer. Doped with phosphorus slurry containing 30% phosphorus, after sintering the electrode, a highly doped area square is obtained in the electrode contact area, and the resistance of the highly doped area square is 20Ω, forming an ohmic contact;

[0036] (2) Diffusion in the atmosphere of phosphorus oxychloride after printing high-concentration phosphorous slurry in the electrode grid linear screen:

[0037] ①. At the beginning of the diffusion, the POCl is introduced 3 gas:

[0038] Phosphorous slurry is ...

Embodiment 3

[0044] A preparation method for a selective emitter solar cell, which comprises the following steps:

[0045] (1) When printing electrodes, mix high-concentration phosphorus slurry into the electrode slurry:

[0046] First, evenly coat the surface of the silicon wafer with 5% phosphoric acid aqueous solution. The thickness of the phosphoric acid aqueous solution is 50 μm. The phosphoric acid aqueous solution is diffused on the surface of the silicon wafer. Doped with phosphorus slurry containing 30% phosphorus, after sintering the electrode, a highly doped area square is obtained in the electrode contact area, and the resistance of the highly doped area square is 25Ω, forming an ohmic contact;

[0047] (2) Diffusion in the atmosphere of phosphorus oxychloride after printing high-concentration phosphorous slurry in the electrode grid linear screen:

[0048] ①. At the beginning of the diffusion, the POCl is introduced 3 gas:

[0049] Phosphorus slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com