Biomacromolecular hydrogel biological stent and preparation method thereof

A bio-macromolecule and bio-scaffold technology is applied in the field of alginate hydrogel bio-scaffold and its preparation, which can solve the problems of residual, residual and high cost of bio-scaffolds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

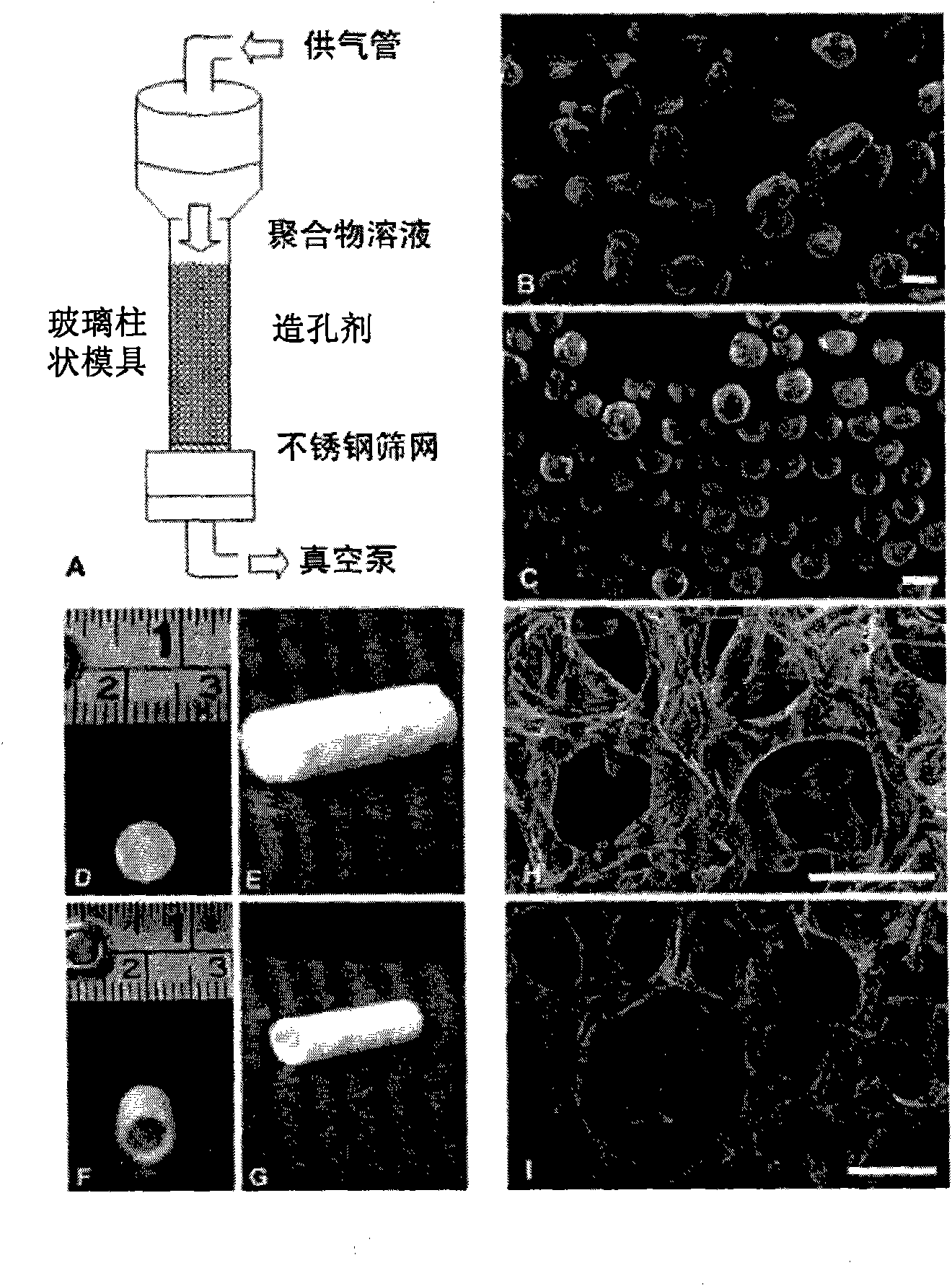

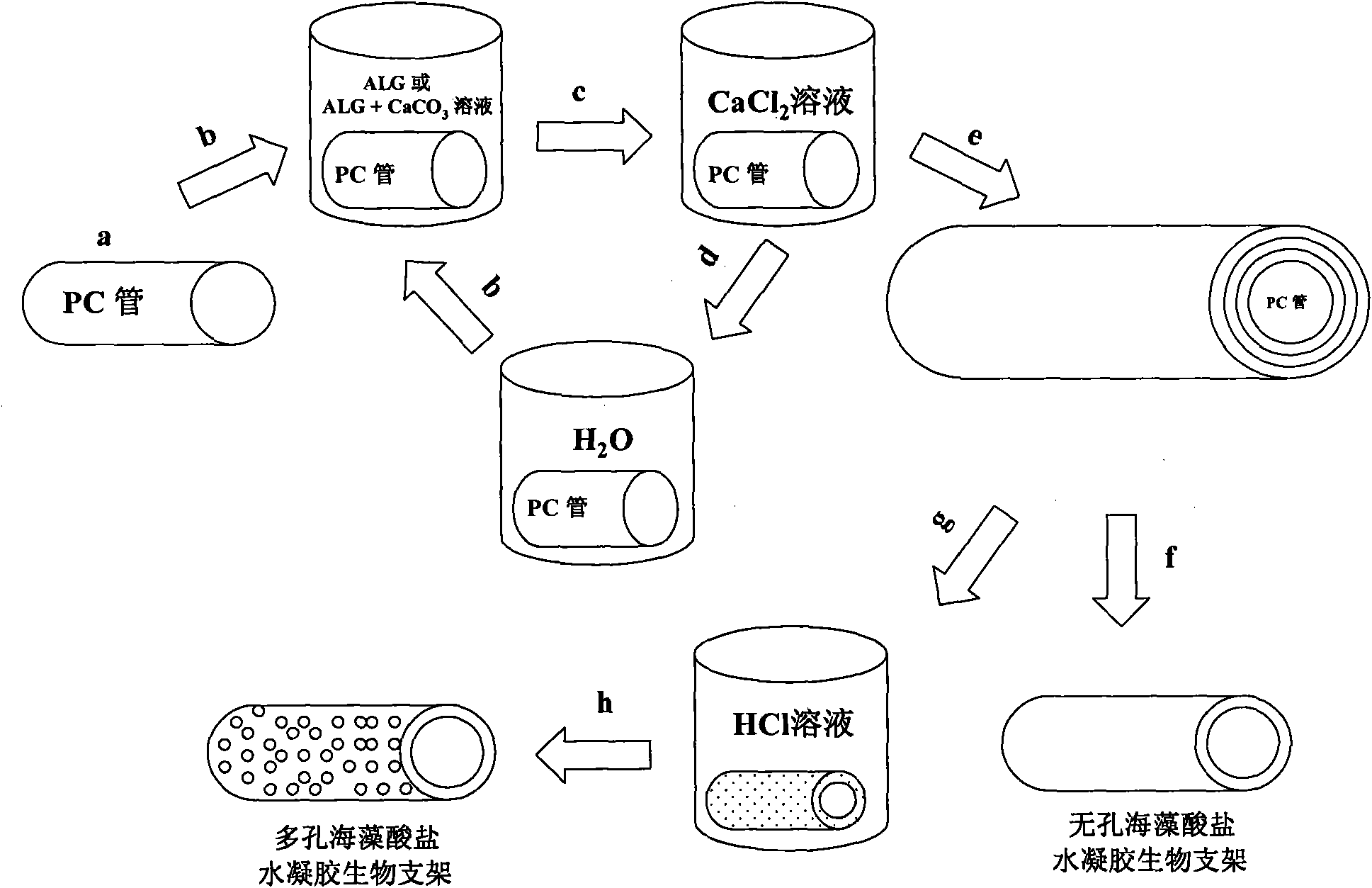

[0056] For the preparation process of alginate hydrogel bioscaffold, see figure 2 , the prepared tubular hydrogel bioscaffold see image 3 .

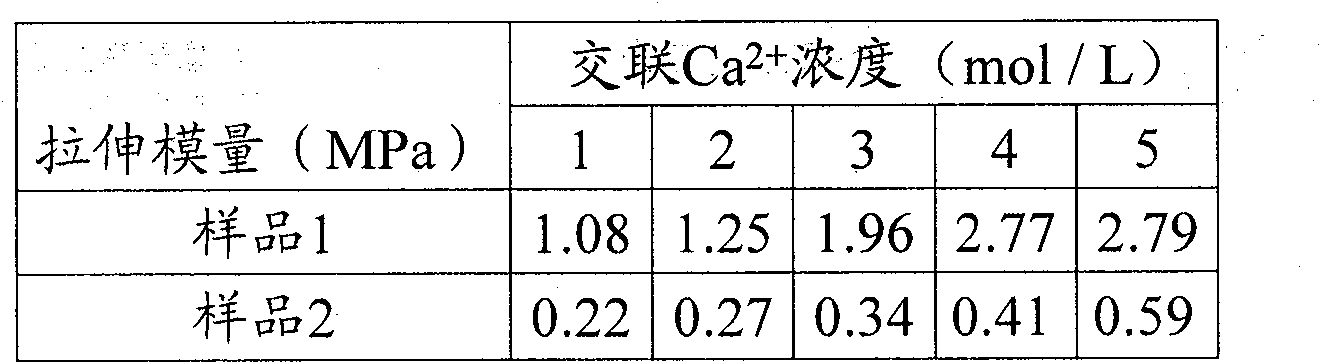

[0057] First cut the polycarbonate tube (a), seal both ends of the tube with polyethylene parafilm, and then immerse the polycarbonate tube in 30mg / mL sodium alginate aqueous solution for 5min (b), the surface of the polycarbonate tube adsorbs sodium alginate Then take out and immerse in 4mol / L GaGl 2 10min in aqueous solution to make it completely cross-linked (c), and then placed in pure water for 10min to wash excess Ca 2+ and Cl - (d). Repeat the above steps as needed to prepare multilayer hydrogel (e), and separate the multilayer hydrogel layer by layer to obtain tubular hydrogel bioscaffolds (f) with different diameters. To prepare porous hydrogel bioscaffolds, add CaCO to aqueous sodium alginate 3 Granules, mixed well, prepared as above steps containing CaCO 3 The granular tubular hydrogel bioscaffold was soaked in 1mol / L...

preparation example 2

[0062] First cut the polyethylene tube, seal both ends of the tube with polyethylene parafilm, immerse the polyethylene tube in 20mg / mL potassium alginate aqueous solution for 10min, take it out and immerse it in 3mol / L BaCl2 aqueous solution for 20min to make it completely cross-linked, then Soak in pure water for 20min to clean excess Ba 2+ and Cl - , and finally immersed in 10mg / mL chitosan aqueous solution for 20min to adsorb chitosan through electrostatic action. By repeating the above steps, a hydrogel bioscaffold containing two biomacromolecules, alginate and chitosan, can be prepared. To prepare porous hydrogel bioscaffolds, add BaCO to aqueous potassium alginate 3 Granules, mixed evenly, prepared as above steps containing BaCO 3 The granular tubular hydrogel bioscaffold was soaked in 2mol / L HCl aqueous solution to the BaCO in the scaffold 3 The particles completely dissolve to form CO 2 The porous hydrogel bioscaffold was prepared after washing with pure water. ...

preparation example 3

[0064] First cut the polycarbonate tube, seal both ends of the tube with polyethylene parafilm, and immerse the polycarbonate tube in a solution containing MgCO 3 The particles were soaked in 10mg / mL polyvinyl alcohol aqueous solution for 20min, then taken out and immersed in 3wt.% glutaraldehyde aqueous solution for 30min to make them completely cross-linked, and then placed in pure water for 60min to clean excess glutaraldehyde. Repeat the above steps as needed, will contain MgCO 3 Granular polyvinyl alcohol hydrogel bioscaffold soaked in 2mol / L HCl aqueous solution to MgCO in the scaffold 3 The particles completely dissolve to form CO 2 The porous polyvinyl alcohol hydrogel bioscaffold was prepared after washing with pure water. Evaporate the porous hydrogel bio-scaffold in a 90° C. dry oven and then immerse it in 3 wt.% gelatin aqueous solution to swell, so that the gelatin active component can be modified on the surface of the hydrogel bio-scaffold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com