Reverse osmosis membrane scale inhibitor

A scale inhibitor and reverse osmosis technology, applied in the field of water treatment chemicals, can solve the problems of pollutant pollution of membrane devices, and achieve the effects of environmental friendliness, long storage period and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

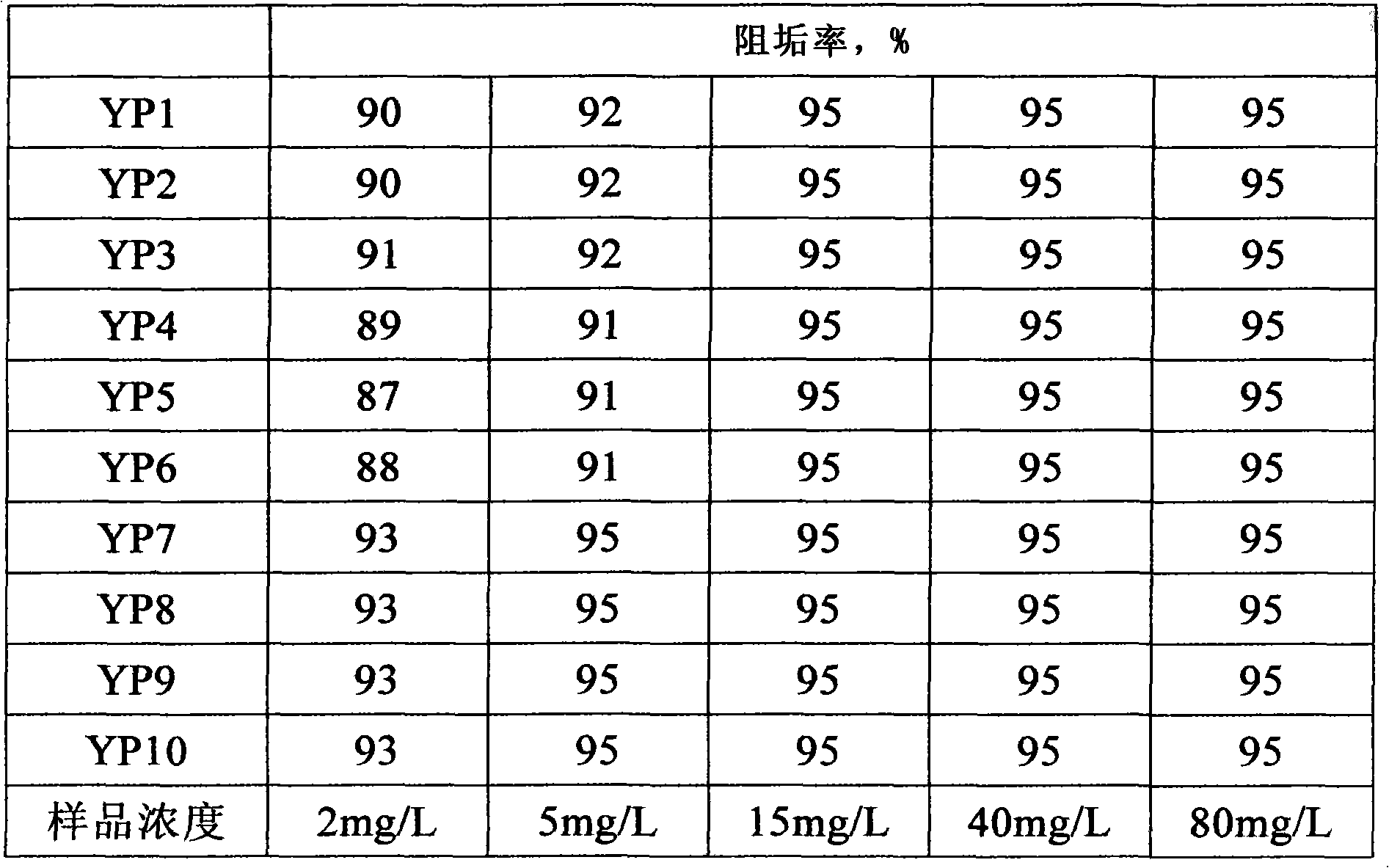

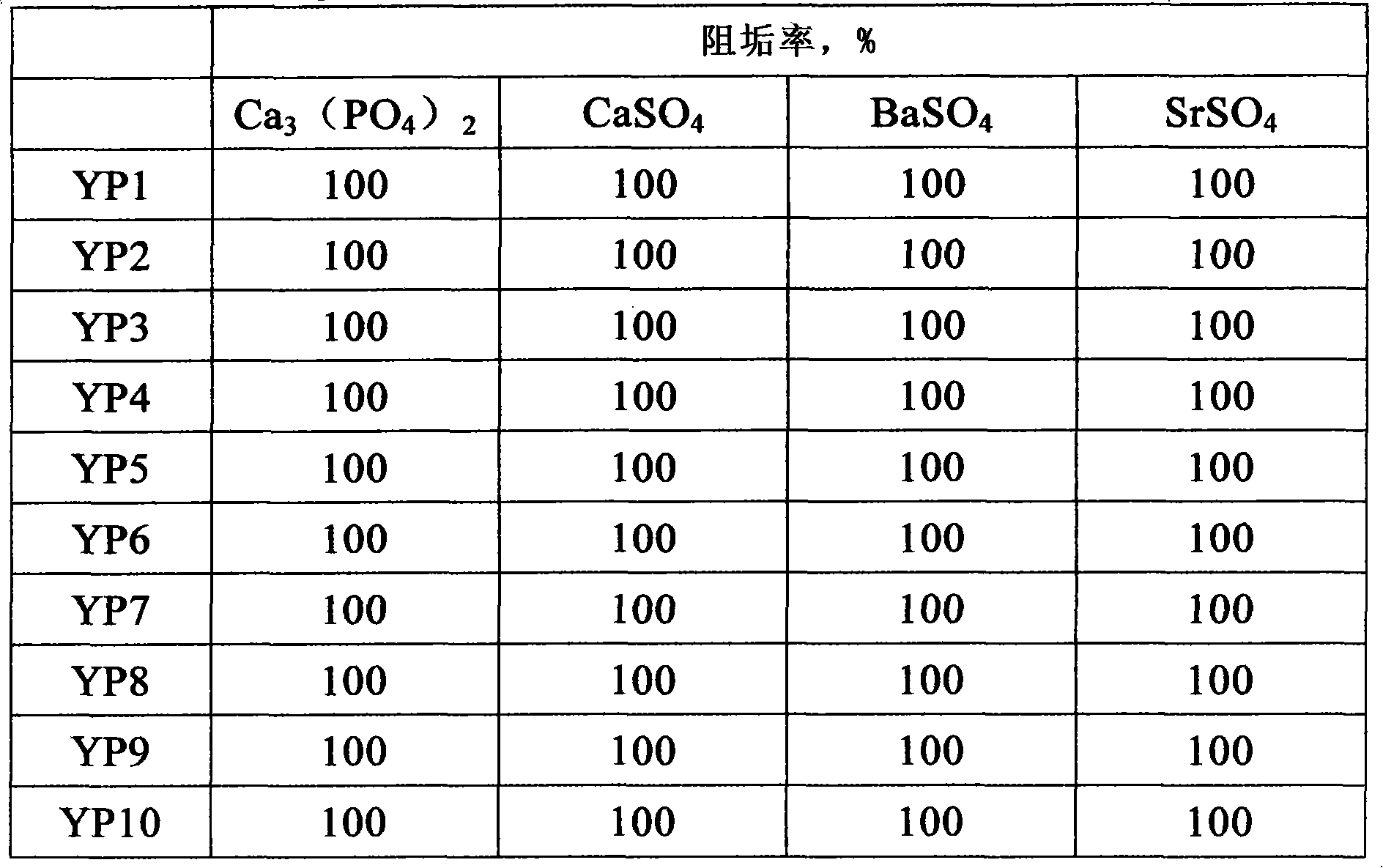

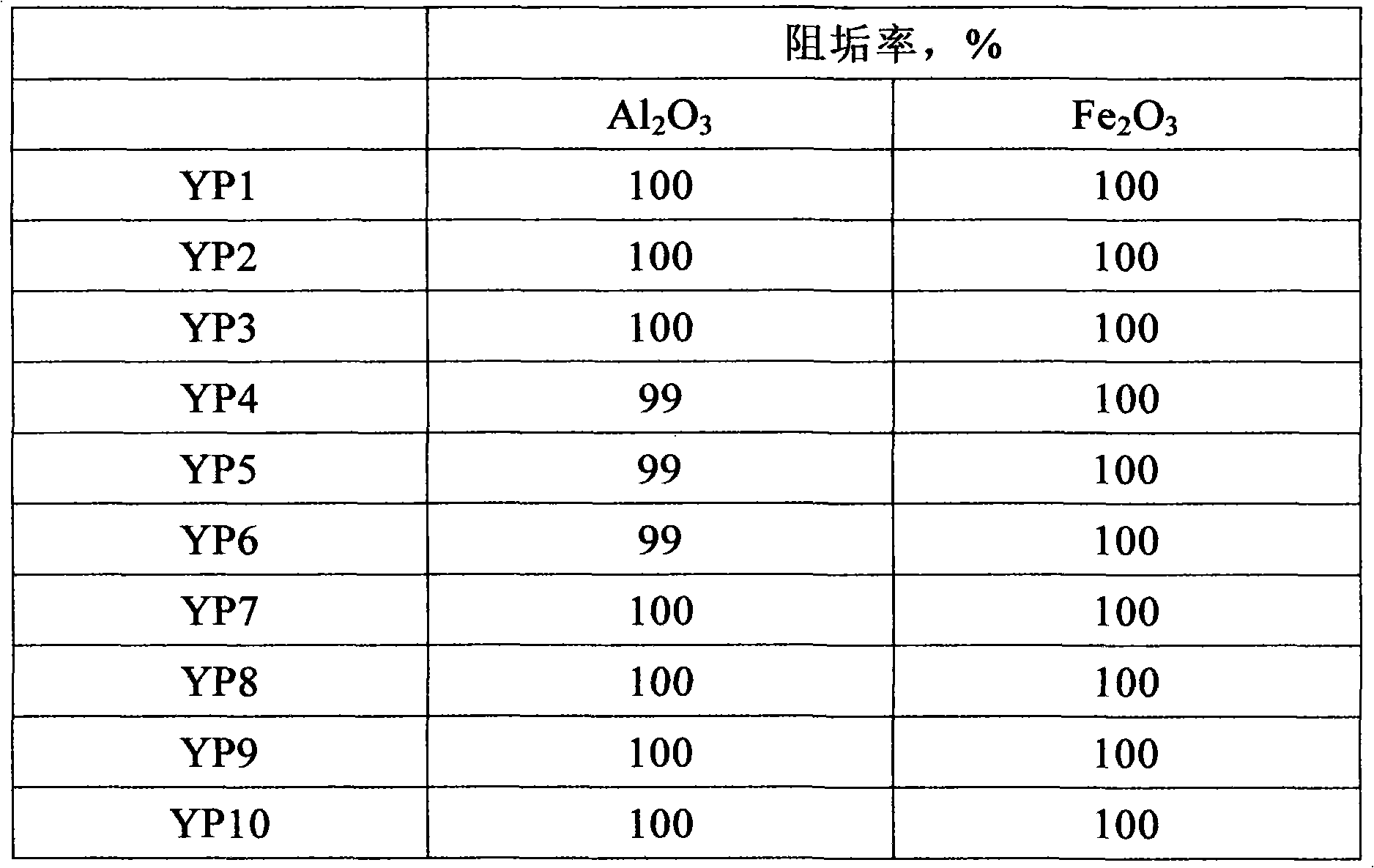

Examples

Embodiment 1

[0026] Add 70g of water into a flask equipped with a stirring device, start stirring, then add 8g of polylactic acid with a molecular weight of 2500, and 22g of acetic acid and phosphonic acid in sequence, and mix evenly after about 30 minutes, stop stirring, and obtain the scale inhibitor sample YP1 of the present invention . Its pH is 1.6 and its solid content is 30 wt%.

Embodiment 2

[0028] Add 50 g of water into a flask equipped with a stirring device, start stirring, then add 5 g of polylactic acid with a molecular weight of 3500, and 45 g of hydroxyethylidene diphosphonic acid in sequence, and mix evenly after about 30 minutes, stop stirring, and obtain the scale inhibitor of the present invention agent sample YP2. Its pH is 1.3 and its solid content is 50 wt%.

Embodiment 3

[0030] Add 55g of water into a flask equipped with a stirring device, start stirring, then add 10g of polylactic acid with a molecular weight of 35,000, and 35g of (1,2,4-tricarboxy-2-phosphonobutane) successively, and it will be ready after about 30 minutes. Mix evenly, stop stirring, and obtain the antiscalant sample YP3 of the present invention. Its pH is 1.2 and its solid content is 45% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com