Efficient anti-pollution isolation liquid for well cementation and preparation method thereof

An isolation fluid and anti-pollution technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor cement ring cementation quality and low displacement efficiency of two-phase fluid, avoid annular air channeling, and improve displacement. Efficiency, good chemical compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

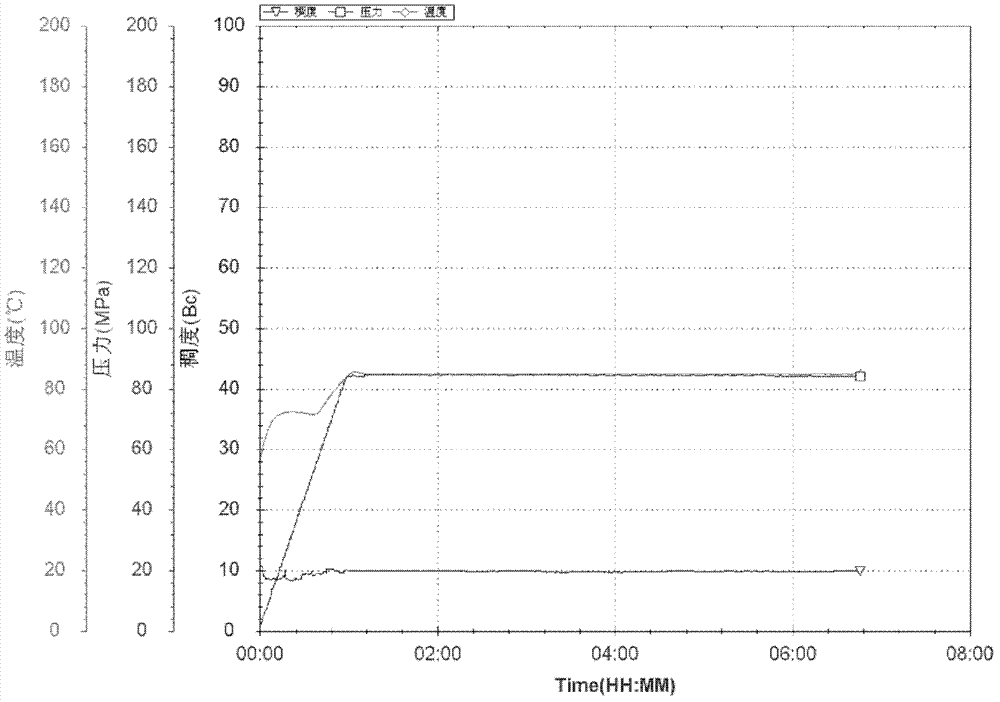

Embodiment 1

[0047] Wet preparation process: put 100 parts of water in the pulp cup, put 8 parts of sodium bentonite, stir for 3 hours; then put in 0.65 parts of sodium humate, 0.6 parts of hydroxyethyl cellulose, 0.5 parts of sodium sulfomethyl gallate , 0.1 part of sodium carbonate, stir well and adjust the performance to meet the requirements, put in 80 parts of barite powder to the required density; finally add 15 parts of sodium hydroxide to adjust the liquid pH between 8-11, and finally add 0.1 part of tributyl phosphate Stir for 1 hour to get density 1.3g / cm 3 High-efficiency anti-pollution isolation fluid for cementing.

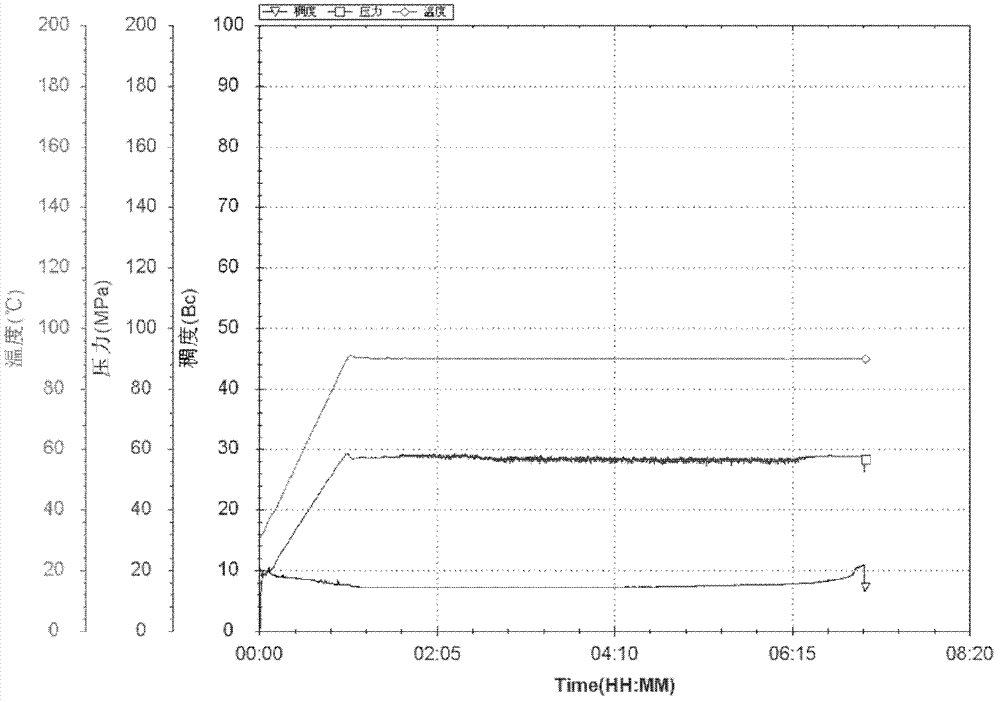

Embodiment 2

[0049] Wet preparation process: put 100 parts of water in the pulp cup, put in 15 parts of polyethylene glycol, stir for 3 hours; then put in 3 parts of sodium sulfomethyl humate, 1 part of sodium carboxymethyl cellulose, 2 parts of iron Sodium chromium lignosulfonate, 5 parts calcium carbonate, stir evenly and adjust the performance to meet the requirements, put in 30 parts of ilmenite powder to the required density; finally add 10 parts of potassium hydroxide to adjust the pH of the spacer between 8-11, Finally, add 0.3 part of phenylethanol oleate and stir for 1 hour to obtain a density of 1.8g / cm 3 High-efficiency anti-pollution isolation fluid for cementing.

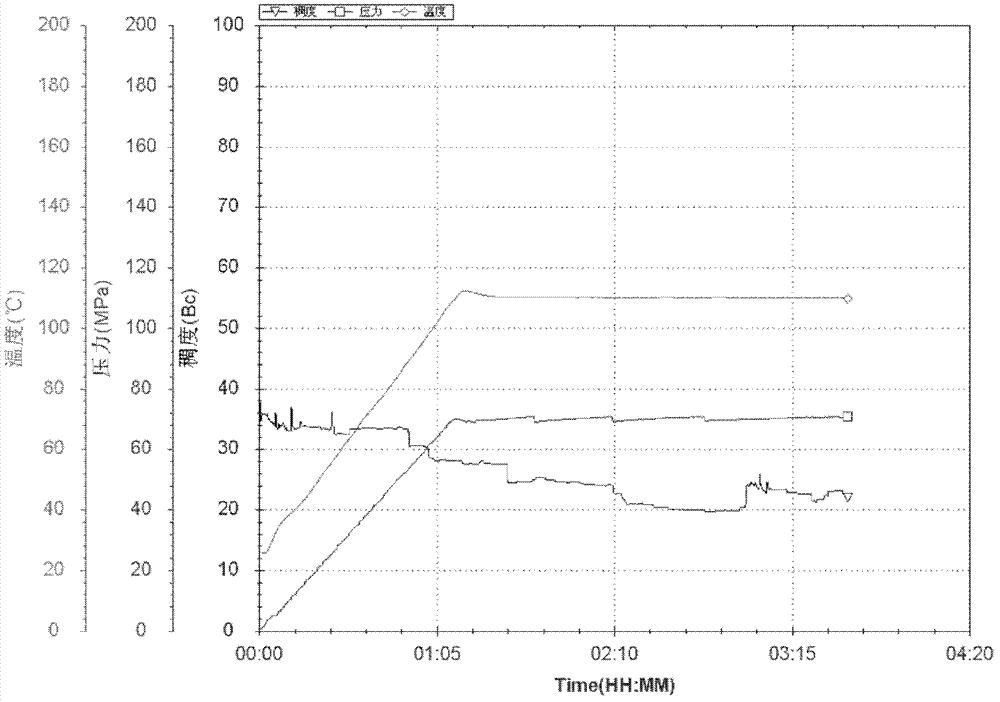

Embodiment 3

[0051] Dry preparation process: dry mix 28 parts of hydroxypropyl starch ether, 4 parts of sulfomethyl phenolic resin, 2 parts of sepiolite, 0.5 part of sodium carbonate, and 240 parts of magnetite powder into a mixed powder according to the weight ratio; Add 5 parts of sodium sulfomethyl digallate, 12 parts of sodium bicarbonate, and 0.2 parts of lauryl phenylacetate into 100 parts of clean water to prepare the base liquid of the isolation liquid and stir evenly; finally add the mixed powder to the base liquid of the isolation liquid ,Stir for 2 hours to get density 2.1g / cm 3 High-efficiency anti-pollution isolation fluid for cementing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com