Preparation method for anode material of lithium ion battery

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems that materials cannot be synthesized on a large scale, the electrode cycle performance is deteriorated, and the coating effect cannot be achieved, and the phenomenon of product agglomeration can be avoided. , The effect of high temperature residence time is short, which is convenient for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

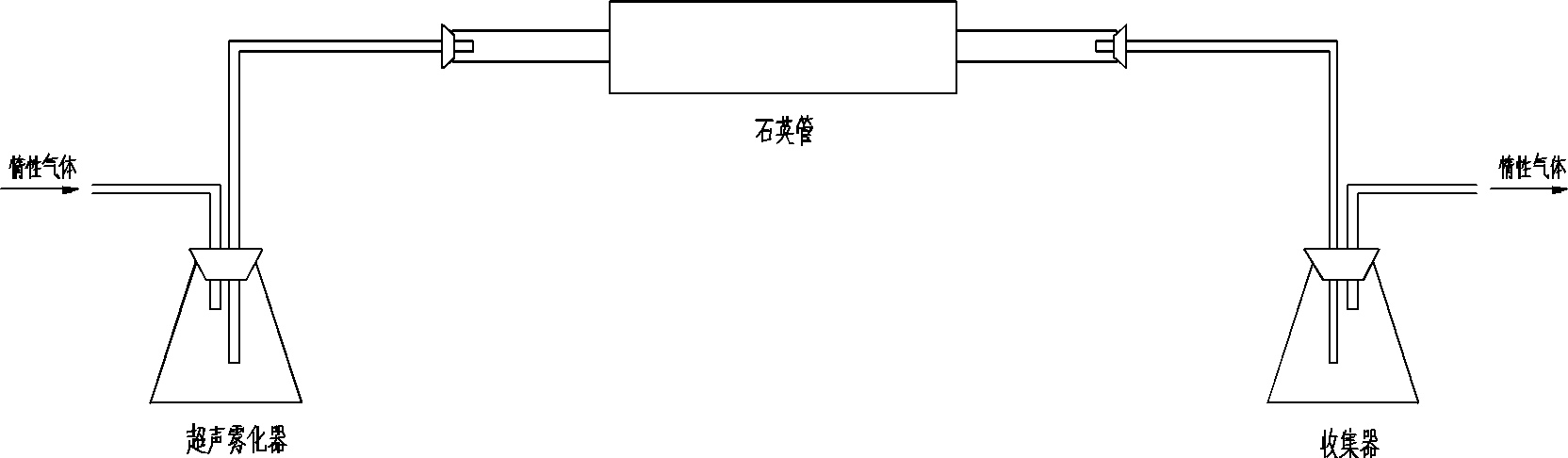

[0020] Heat the quartz tube to a certain temperature, and pass high-purity argon or nitrogen to keep the temperature in the tube at 1000 degrees, the gas flow rate is constant at 0.2 L / min, and ventilate for 0.5 hours.

[0021] Stir the pre-prepared reaction liquid evenly and put it into an ultrasonic atomizer. The reaction liquid is composed of 1L of methanol, 10g of nickel acetylacetonate, and 80g of stannous chloride.

[0022] Increase the flow rate of the inert gas to 0.5~1L / min, and turn on the power supply of the ultrasonic nebulizer. The particles obtained in the collector are washed with methanol or ethanol, and dried to obtain a tin-nickel-carbon nanocomposite material, which is the negative electrode material of the lithium ion battery.

[0023] The above-prepared composite nano negative electrode material is the positive electrode, the lithium sheet is the counter electrode, the electrolyte is the EC / DMC (Vol 1:1) solution of 1M LiPF6, and the diaphragm is a composi...

Embodiment 2

[0025] Heat the quartz tube to a certain temperature, and pass high-purity argon or nitrogen to keep the temperature in the tube at 1200 degrees, the gas flow rate is constant at 0.2 L / min, and ventilate for 0.5 hours.

[0026] Stir the pre-prepared reaction liquid evenly and put it into an ultrasonic atomizer. The reaction liquid is 1L of methanol, 20g of nickel acetylacetonate, and 100g of tin chloride.

[0027] Increase the flow rate of the inert gas to 0.5~1L / min, and turn on the power supply of the ultrasonic nebulizer. The particles obtained in the collector are washed with methanol or ethanol, and dried to obtain a tin-nickel-carbon nanocomposite material, which is the negative electrode material of the lithium ion battery.

[0028] The above-prepared composite nano negative electrode material is the positive electrode, the lithium sheet is the counter electrode, the electrolyte is the EC / DMC (Vol 1:1) solution of 1M LiPF6, and the diaphragm is a composite diaphragm of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com