Centralized purification treatment process and device of waste gas in spandex production process

A production process and purification treatment technology, which is applied in the direction of chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of production plant and surrounding environmental hazards, environmental pollution, etc., and achieve the goals of preventing pollution, simplifying the process, and saving space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

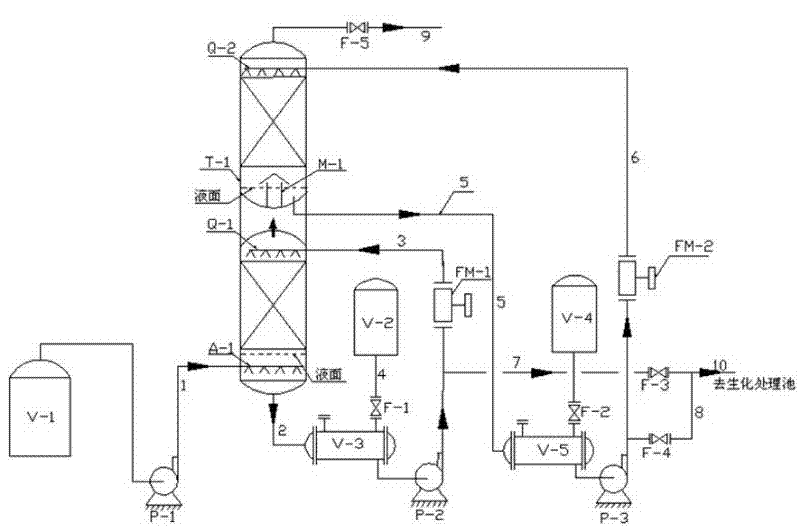

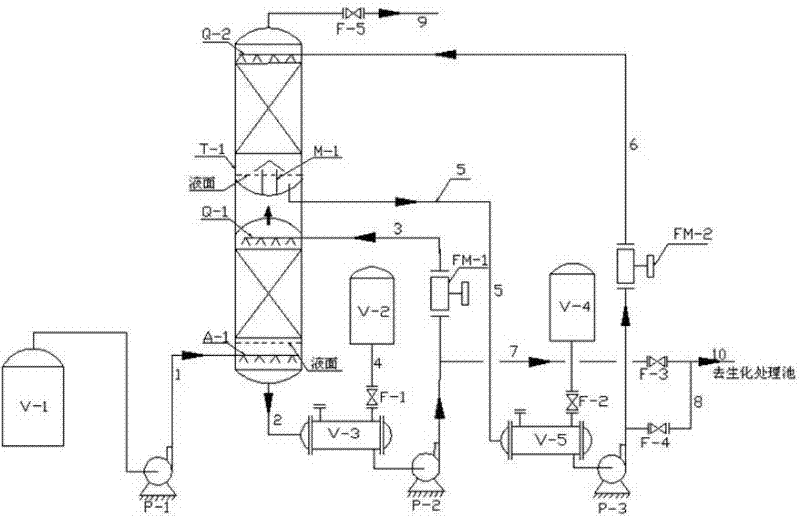

[0028] Example 1: Waste gas absorption during the production process of annual production of 3kt spandex with dimethylacetamide (DMAc) as solvent

[0029] The operation steps of the exhaust gas absorption method in the spandex production workshop are attached Figure 1 shown. The system is mainly composed of absorption tower, pure water storage tank, rare organic acid absorption liquid storage tank and other equipment. There are metering and control instruments and pipelines between each equipment. The waste gas collected in the waste gas storage tank V-1 (containing 5 mg / m 3 Dimethylacetamide vapor, 20 mg / m 3 Acetic acid vapor, 40 mg / m 3 formaldehyde, 56 mg / m 3 Dimethylamine gas and 13 mg / m 3 Ammonia) with blower P-1 through pipeline 1 and gas distributor A-1 into the composite solution absorption unit of absorption tower T-1 (the composite solution is a composite solution composed of 0.1M sodium hydroxide and 0.3M sodium nitrite solution), according to the content o...

Embodiment 2

[0030] Example 2: Waste gas absorption during the production process of annual production of 5kt spandex with dimethylacetamide (DMAc) as solvent

[0031] The operation steps of the exhaust gas absorption method in the spandex production workshop are attached Figure 1 shown. The system is mainly composed of absorption tower, pure water storage tank, rare organic acid absorption liquid storage tank and other equipment. There are metering and control instruments and pipelines between each equipment. The waste gas collected in the waste gas storage tank V-1 (containing 25 mg / m 3 Dimethylacetamide vapor, 12 mg / m 3 formaldehyde, 120 mg / m 3 Acetic acid vapor, 45 mg / m 3 Dimethylamine gas and 16 mg / m 3 Ammonia) with blower P-1 through pipeline 1 and gas distributor A-1 into the composite solution absorption unit of absorption tower T-1 (the composite solution is a composite solution composed of 0.4M sodium carbonate and 0.5M sodium nitrite ), according to the content of exha...

Embodiment 3

[0032] Example 3: Waste gas absorption during the production process of annual production of 10kt spandex with dimethylacetamide (DMAc) as solvent

[0033] The mode of operation is as in Example 1. The waste gas collected in the waste gas storage tank V-1 (containing 50 mg / m3 of dimethylacetamide vapor, 31 mg / m 3 formaldehyde, 400mg / m3 of acetic acid vapor, 100mg / m3 of dimethylamine gas and 5mg / m3 of ammonia gas) with blower P-1 through pipeline 1 and gas distributor A-1 into the composite of absorption tower T-1 Solution absorption unit (the solution is a composite solution composed of 3.0M sodium bicarbonate and 3.5M sodium nitrite), according to the content of exhaust gas components in the gas and the amount of exhaust gas treatment, the flow meter FM-1 is used to control the spraying amount of the composite solution , the spray density of this embodiment is 8m 3 / m 2 h), so that the content of acetic acid in the gas after the complex solution absorption unit is reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com