Double-hindered phenol structure-contained hydrazides compound and preparation method thereof

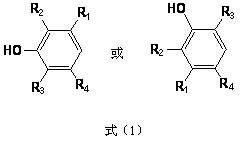

A technology of hindered phenols and hydrazides, which is applied in the field of hydrazides containing double hindered phenol structures and their preparation, and can solve the problems of low molecular weight, compatibility, yellowing resistance, migration resistance and insufficient antioxidant capacity , to achieve the effects of increased molecular weight, enhanced thermal oxidation resistance, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (2) Add 125g (0.5mol) methyl 3-methyl-4-hydroxy-5-tert-butylpropionate and 400ml methanol to a 1000ml three-neck flask, add 40% hydrazine hydrate 100g ( 0.8mol), stirred at room temperature for 8 hours. The solvent was evaporated under reduced pressure and dried to obtain 116.9 g of 3-methyl-4-hydroxy-5-tert-butylphenylpropanohydrazide, content ≥ 98.1% (HPLC), yield 93.5%, white powdery solid, Mp: 107-109°C.

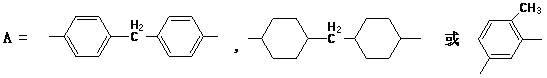

[0039] (3) In a 500ml three-necked flask, add 50g (0.2mol) of 3-methyl-4-hydroxy-5-tert-butylphenylpropionohydrazide and 200mL of dichloromethane, and stir to dissolve. Cool down to 5-10°C, slowly add about 50ml of a dichloromethane solution of 25g 4,4'-diphenylmethane diisocyanate (MDI, 0.1mol) dropwise under stirring, and react at about 10°C for 5 hours after the dropwise addition is completed. Suction filtration and drying gave 70.1 g of white solid, content 98.5%, yield 93.4%, mp: 219-221°C. The final product structure is:

[0040] .

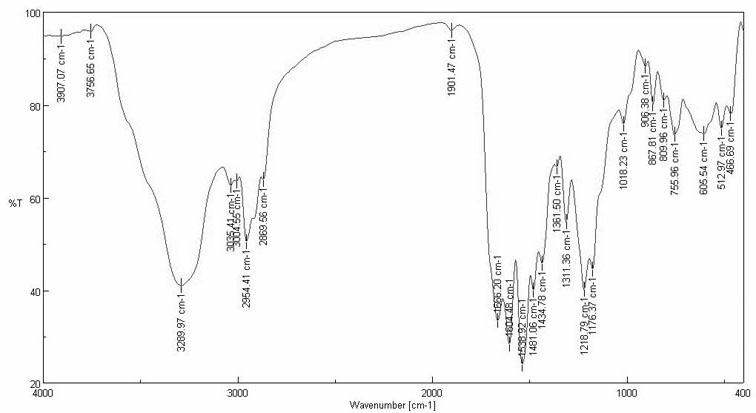

[0041] The NMR da...

Embodiment 2

[0045] (2) In a 1000ml three-necked flask, add 132g (0.5mol) ethyl 3-methyl-4-hydroxy-5-tert-butylpropionate and 400ml cyclohexane, and add 40wt.% hydrated Hydrazine 100g (0.8mol), stirred at room temperature for 8 hours. The solvent was evaporated under reduced pressure and dried to obtain 113.5 g of 3-methyl-4-hydroxy-5-tert-butylphenylpropanohydrazide, content ≥ 98.1% (HPLC), yield 90.8%, white powdery solid, Mp: 107-109°C.

[0046] (3) In a 500ml three-necked flask, add 50g (0.2mol) of 3-methyl-4-hydroxy-5-tert-butylphenylpropionohydrazide and 200mL of dichloromethane, and stir to dissolve. Cool down to 2-5°C, slowly add 23.6g of 4,4'-dicyclohexylmethane diisocyanate (HMDI, 0.09mol) in dichloromethane solution about 50ml dropwise under stirring, after the dropwise addition, react at about 5°C for 6 hours, filtered with suction, and dried to obtain 58.3 g of a white solid, with a content of 98.8%, and a yield of 85%. The final product structure is:

[0047] .

[0048...

Embodiment 3

[0050] (2) Add 125g (0.5mol) methyl 3-methyl-4-hydroxy-5-tert-butylpropionate and 400ml toluene to a 1000ml three-necked flask, add 40wt% hydrazine hydrate 100g ( 0.8mol), stirred at room temperature for 8 hours. The solvent was evaporated under reduced pressure and dried to obtain 115.4 g of 3-methyl-4-hydroxy-5-tert-butylphenylpropanohydrazide, content ≥ 98.5% (HPLC), yield 92.3%, white powdery solid, Mp: 107-109°C.

[0051] (3) In a 500ml three-necked flask, add 50g (0.2mol) of 3-methyl-4-hydroxy-5-tert-butylphenylpropionohydrazide and 200mL of dichloromethane, and stir to dissolve. Cool down to 5-10°C, slowly add about 60ml of a dichloromethane solution of 17.4g toluene diisocyanate (TDI, 0.1mol) dropwise under stirring, after the dropwise addition, react at about 10°C for 4 hours, filter with suction, and dry to obtain White solid 60.7g, content 99.0%, yield 90%. The final product structure is:

[0052] .

[0053] Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com