Preparation method of white-light phosphor

A fluorescent powder and white light technology, which is applied in the field of preparation of rare earth inorganic oxide luminescent materials, can solve the problems of great difference in LED decline, insufficient luminous efficiency of phosphor powder, and color difference, and achieve excellent luminous performance and product yield High, high luminous efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described below in conjunction with accompanying drawing:

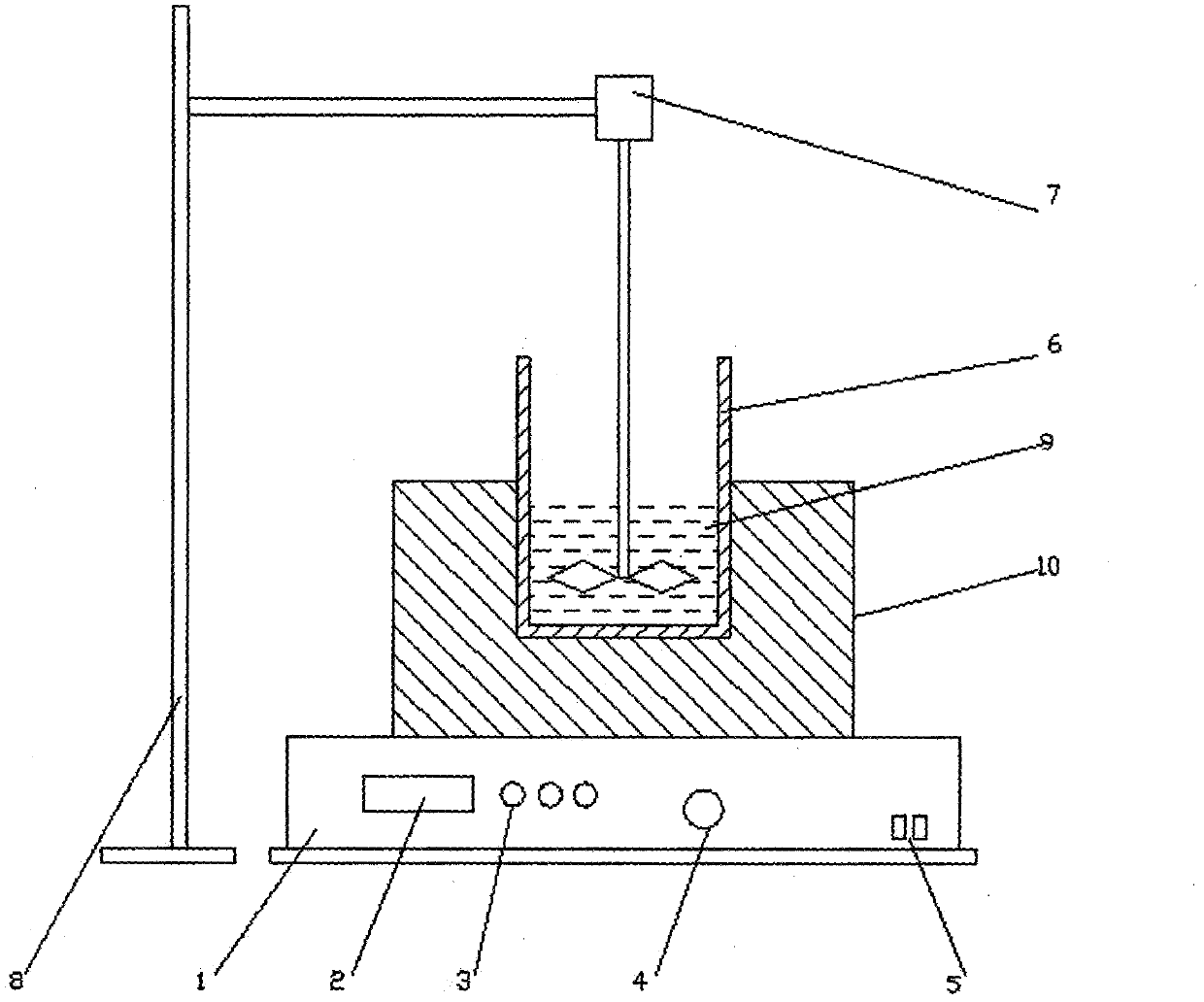

[0074] figure 1 Shown is the liquid phase gel state diagram of the product, and each preparation parameter must be strictly controlled and operated in sequence.

[0075] The product liquid phase gel is carried out in a beaker, the beaker 6 is placed on the electric heating mantle 10, the electric heating mantle 10 is placed on the electric controller 1, and the electric controller 1 is equipped with a display screen 2, an indicator light 3, and a temperature control knob 4. The power switch 5; the left side of the electric heating mantle 10 is provided with a stirrer bracket 8, which is connected to the stirrer 7, and the stirrer 7 goes deep into the beaker 6 to stir, and the beaker 6 contains a liquid phase gel 9.

[0076] The proportioning amount of the chemical substance material required for preparation is determined according to a preset numerical range, and the unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com