Method for preparing ternary alloy quantum dots in ole-morpholine solvent

A ternary alloy and oleoylmorpholine technology, which is applied in the field of preparing CdSexS1-x ternary alloy quantum dots, can solve the problems of high preparation conditions, high cost of synthesis process, unstable repeatability, etc., and meet the synthesis conditions Mild, mass-producible, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

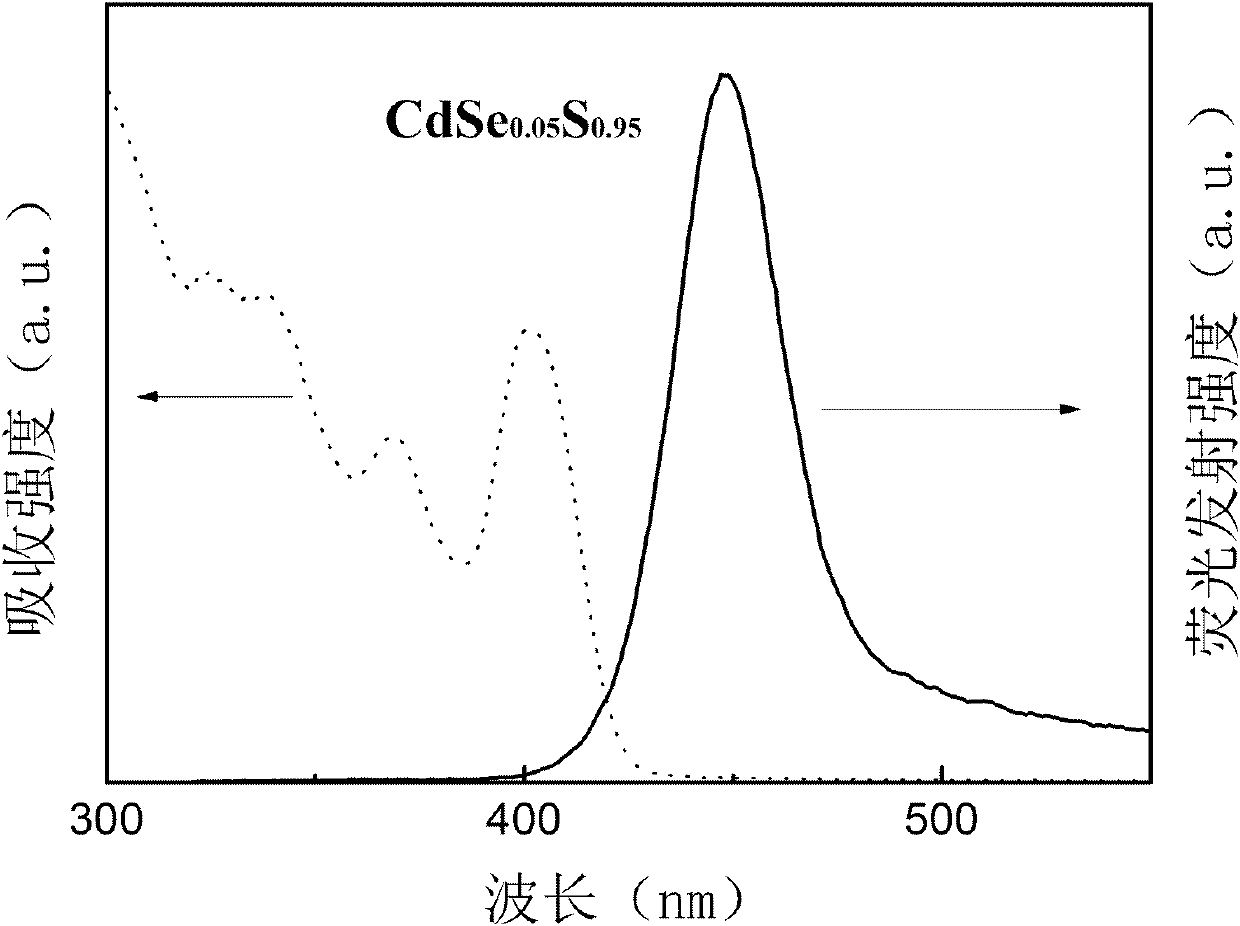

[0027] Embodiment 1: Preparation of CdSe 0.05 S 0.95 Ternary Alloy Quantum Dots

[0028] (1) Heat 0.130g (1mmol) cadmium oxide, 5mL (15mmol) oleic acid and 9mL oleoylmorpholine to dissolve, then cool to room temperature to obtain a cadmium-containing precursor;

[0029] (2) Heat 0.004g (0.05mmol) Se powder, 0.030g (0.95mmol) S powder and 3mL oleoylmorpholine to dissolve, and cool to room temperature to obtain a precursor solution containing Se and S;

[0030] (3) Add the above two precursor solutions into a 50mL three-necked bottle, heat it to 110°C under stirring, keep it warm for 1 hour to fully mix the two precursor solutions, and then heat it to 210°C at a heating rate of 15°C / min. °C, stop heating after 1 hour of reaction;

[0031] (4) Take out the reaction solution and add it to methanol at normal temperature to precipitate the crude product of quantum dots. After the crude product is centrifuged and washed, it is dissolved in toluene to obtain the CdSe-containing 0....

Embodiment 2

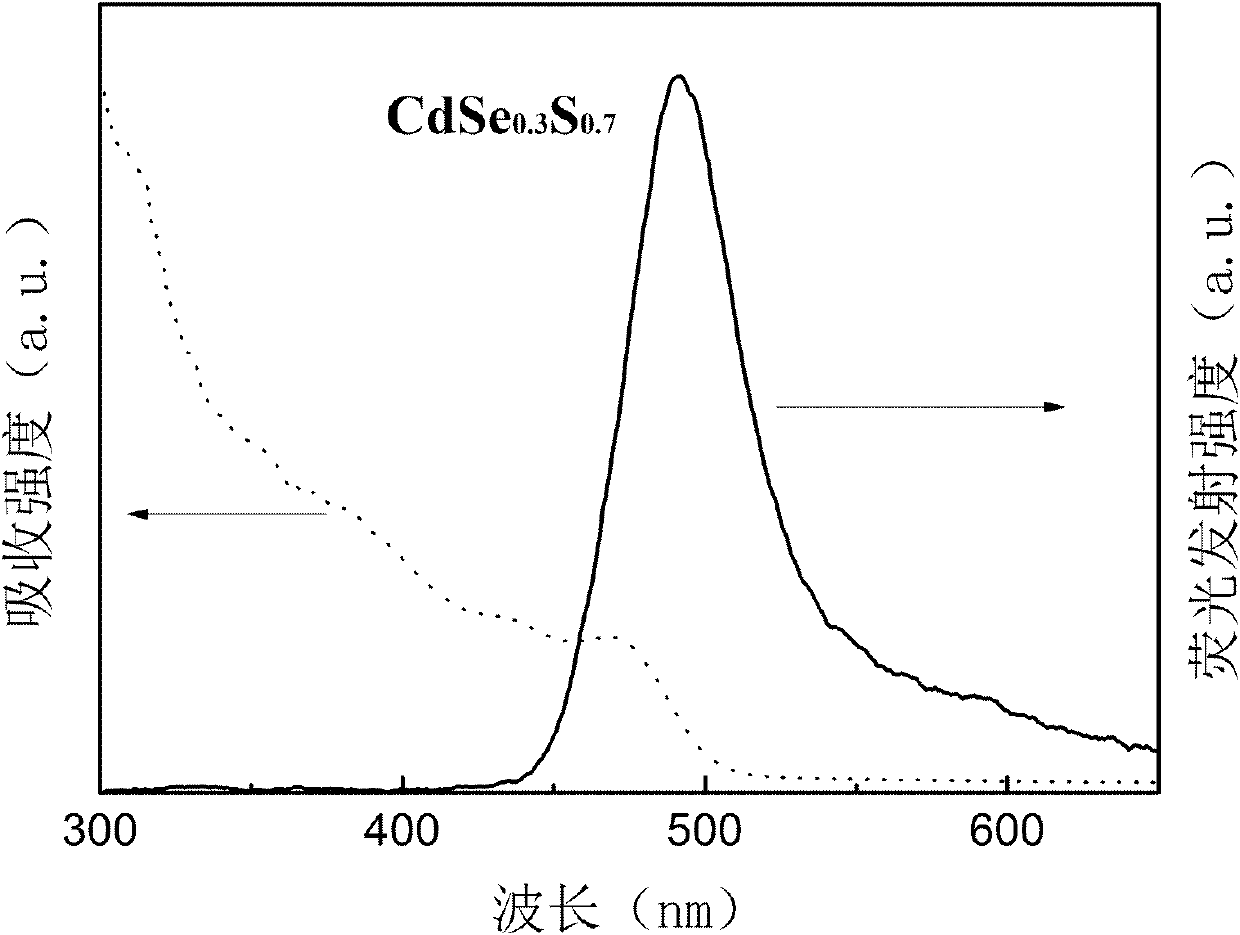

[0034] Embodiment 2: Preparation of CdSe 0.3 S 0.7 Ternary Alloy Quantum Dots

[0035] (1) Heat 0.266g (1mmol) cadmium acetate, 1.024g (4mmol) palmitic acid and 10mL oleoylmorpholine to dissolve, then cool to room temperature to obtain a cadmium-containing precursor;

[0036] (2) Heat 0.024g (0.3mmol) Se powder, 0.022g (0.7mmol) S powder and 4mL oleoylmorpholine to dissolve, and cool to room temperature to obtain a precursor solution containing Se and S;

[0037] (3) Add the above two precursors into a 50mL three-necked bottle, heat it to 120°C under stirring, keep it warm for 50min to fully mix the two precursors, and then heat it to 220°C at a heating rate of 12°C / min , stop heating after reacting for 2 hours;

[0038] (4) Take out the reaction solution and add it to methanol at normal temperature to precipitate the crude product of quantum dots. After centrifugation, washing, and dissolving with toluene, the CdSe-containing 0.3 S 0.7 Toluene solution of ternary alloy q...

Embodiment 3

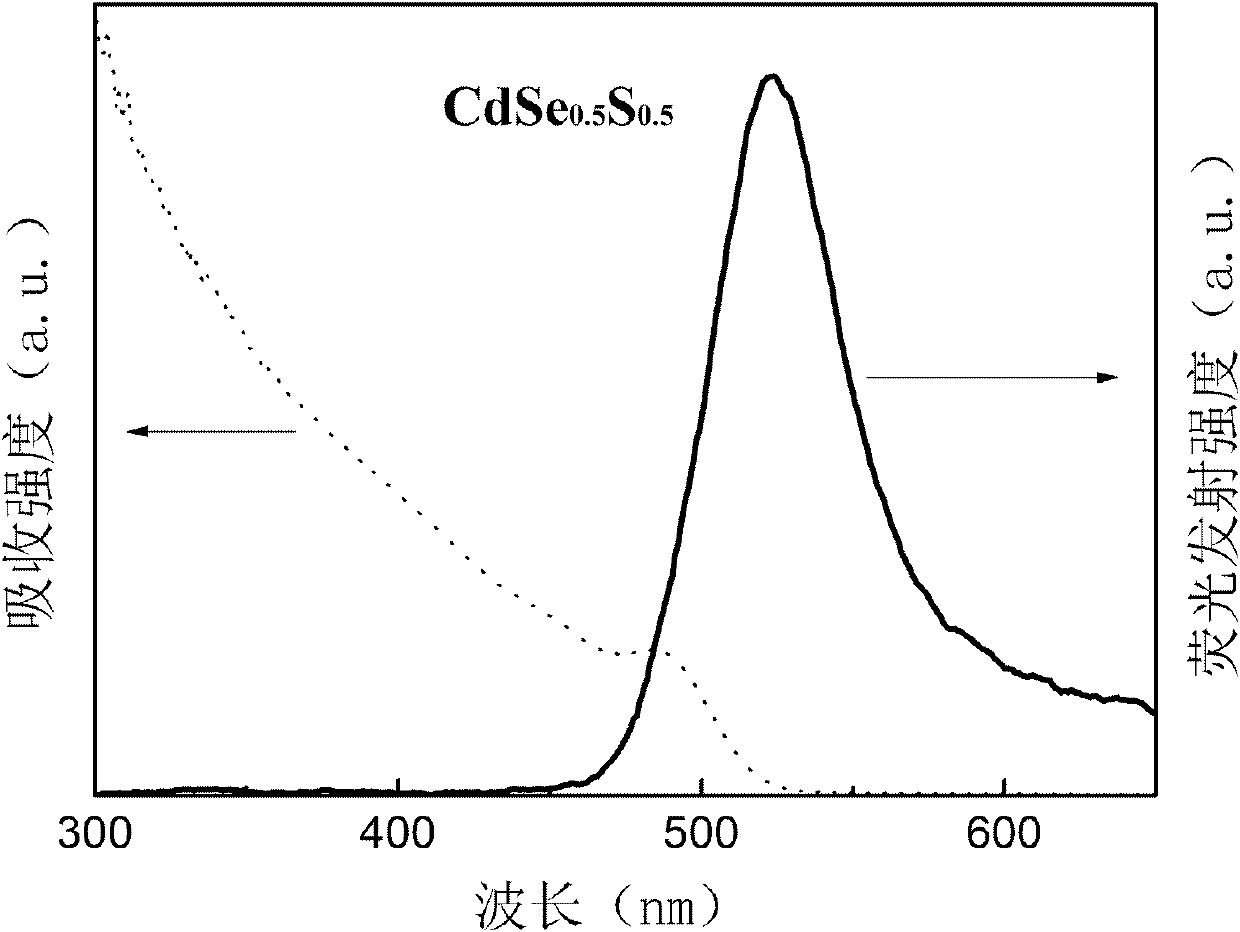

[0041] Embodiment 3: Preparation of CdSe 0.5 S 0.5 Ternary Alloy Quantum Dots

[0042] (1) Heat 0.678g (1mmol) cadmium stearate, 0.684g (3mmol) myristic acid and 10mL oleoylmorpholine to dissolve, and then cool to room temperature to obtain a cadmium-containing precursor;

[0043] (2) Heat 0.039g (0.5mmol) Se powder, 0.016g (0.5mmol) S powder and 5mL oleoylmorpholine to dissolve, and cool to room temperature to obtain a precursor solution containing Se and S;

[0044] (3) Add the above two precursor solutions into a 50mL three-necked bottle, under the action of a magnetic stirring heating mantle, first heat to 130°C, keep warm and stir for 40min to fully mix the two precursor solutions, and then mix the two precursor solutions at 10°C / The heating rate of min is heated to 230°C, and the heating is stopped after 3 hours;

[0045] (4) Take out the reaction solution and add it to propanol at normal temperature to precipitate the crude product of quantum dots. After centrifugat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com